Full-automatic piece separation robot

A robotic and fully automatic technology, applied in the direction of manipulators, program-controlled manipulators, glass manufacturing equipment, etc., can solve problems such as damage, difficulty in realization, and difficulty in moving large pieces of glass at will, achieving flexibility, easy processing and recycling, and realization of human The effect of computer interaction function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

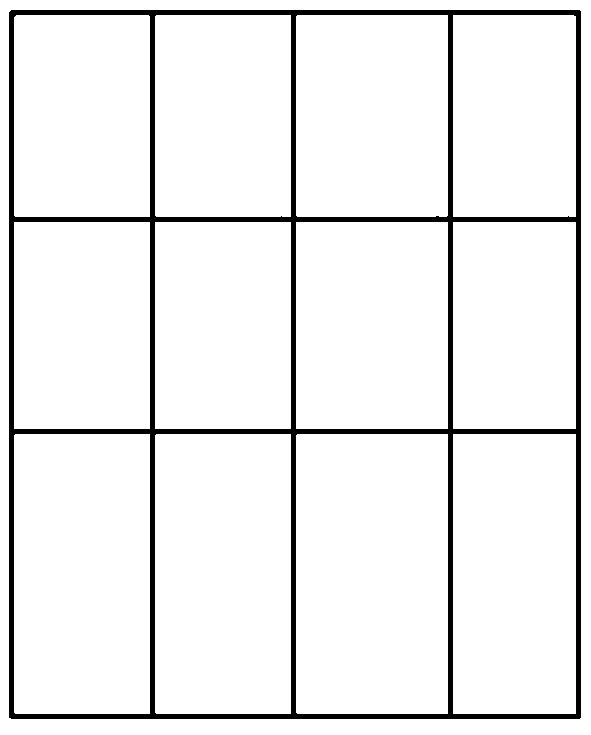

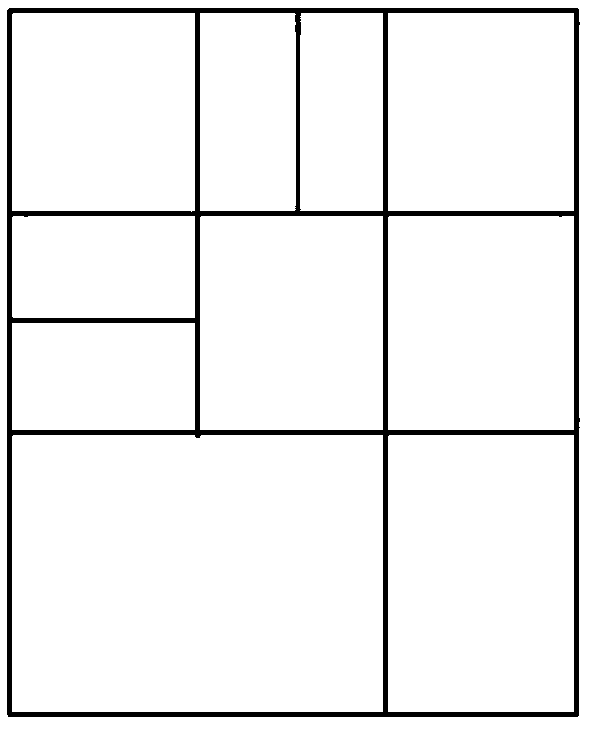

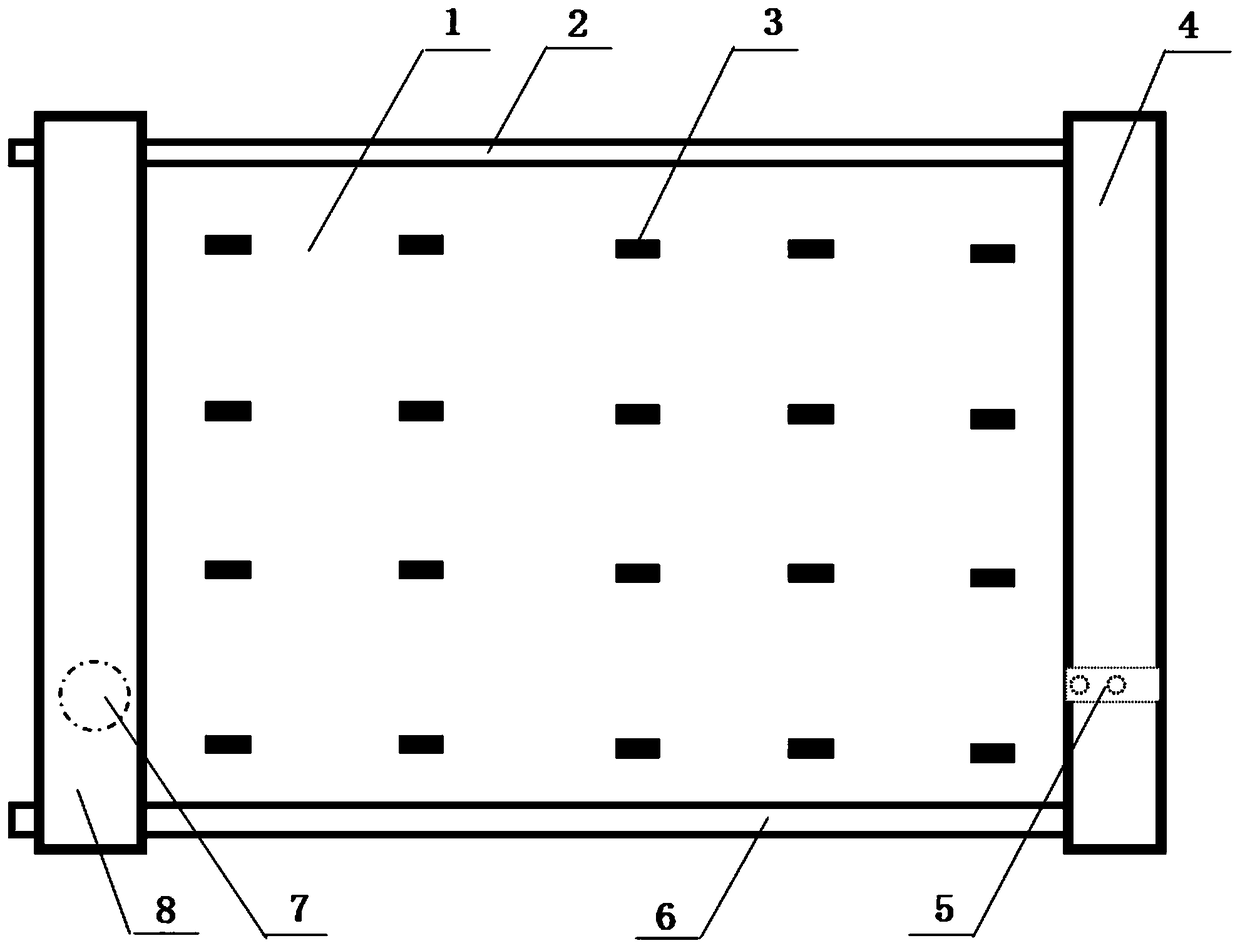

[0035] A fully automatic sharding robot, such as Figure 3 to Figure 5 As shown, it includes a fragmentation platform 1, a fragmentation robot arm 4, a sorting robot arm 8 and a control system. The slicing table is composed of multiple groups of rollers 3 and linear guides 2 and 6 arranged in parallel on both sides thereof, and the glass 9 to be sharded is transported forward by the rollers; the slicing mechanical arm and the sorting mechanical arm The parallel straddle is installed on the upper ends of two linear guide rails, and can move on the linear guide rails respectively. A waste glass transmission mechanism 10 and a waste glass storage container 11 are installed below the slicing table. In this embodiment, the waste glass transmission mechanism adopts a conveyor belt mechanism, and the waste glass after slicing falls into the waste glass storage container from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com