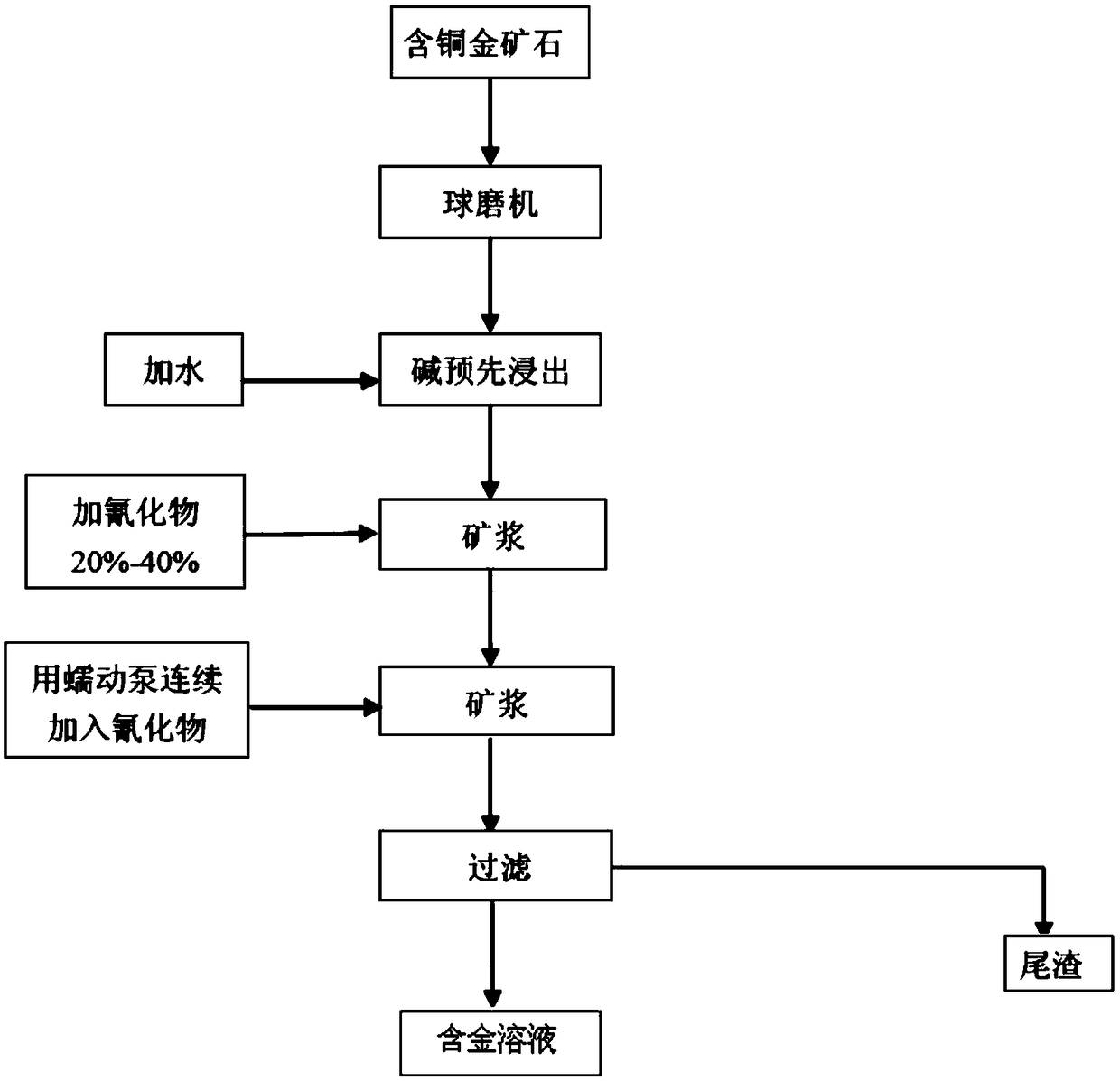

Method of adding chemical reagents continuously for cyanidation leaching copper-bearing gold ores by peristaltic pump in laboratory

A technology of cyanide leaching and peristaltic pump, applied in the direction of improving process efficiency, etc., can solve problems such as high cyanide consumption and environmental pollution, achieve the effects of reducing cyanide consumption, avoiding manual operation errors, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]The laboratory peristaltic pump equipment used in the test is a precision peristaltic pump BT100~2J, with an adjustable flow range: 0.0002ml / min~380ml / min. The conditions of the beneficiation test are: the gold grade of the copper-bearing gold ore used is 3.37g / t, and the copper grade is 0.28%. The copper-containing gold ore is ground by a ball mill until the mass percentage of particles with a particle size of -200 mesh is 90%. Add water and stir until the pulp concentration is 33%, add 8g of calcium oxide per kilogram of ore, pH value 11, pre-leaching time 2 hours; take cyanide solution with a mass concentration of 10%, total 11.6ml, add 2.9ml at one time, leaching 4 After that, the continuous dosing mode with a peristaltic pump was set to 0.0066ml / min, the cyanide concentration in the solution was maintained at 0.019%, and the cyanide leaching time was 26 hours in total. The ore pulp after cyanide leaching is filtered through a medium-speed qualitative filter paper t...

Embodiment 2

[0050] The laboratory peristaltic pump equipment used in the test is a precision peristaltic pump BT100~2J, with an adjustable flow range: 0.0002ml / min~380ml / min. The conditions of the beneficiation test are: the gold grade of the copper-bearing gold ore used is 1.68g / t, and the copper grade is 0.20%. Grind the copper-containing gold ore through a ball mill until the mass percentage of particles with a particle size of -200 mesh is 95%, add water and stir until the pulp concentration is 40%, add 5g of calcium oxide per kilogram of ore, the pH value is 11.5, and the pre-leaching time is 2h. The cyanide solution with a mass concentration of 10%, the total amount is 9.0ml, 1.8ml is added at one time, leached for 2 hours, and then the continuous dosing method with a peristaltic pump is set to 0.0055ml / min, and the cyanide concentration in the solution is maintained at 0.013%. The total cyanide leaching time is 24h. The ore pulp after cyanide leaching is filtered through a medium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com