Copper alloy and application thereof

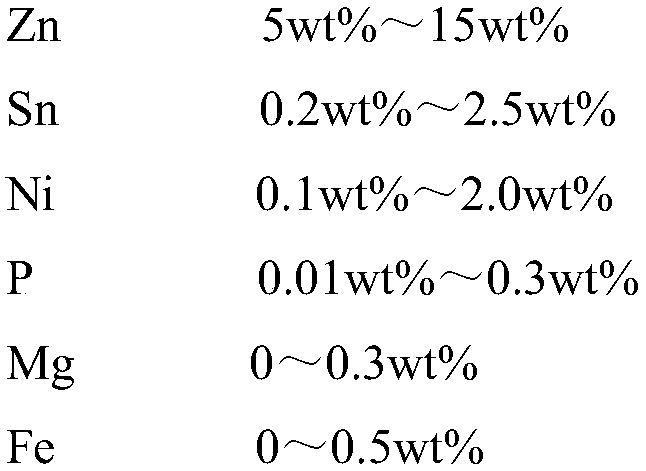

A copper alloy, an unavoidable technology, applied in the field of alloys, can solve the problems of insufficient improvement of bending performance and insufficient control of crystal plane orientation, and achieve the effect of reducing material cost, improving strength and bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

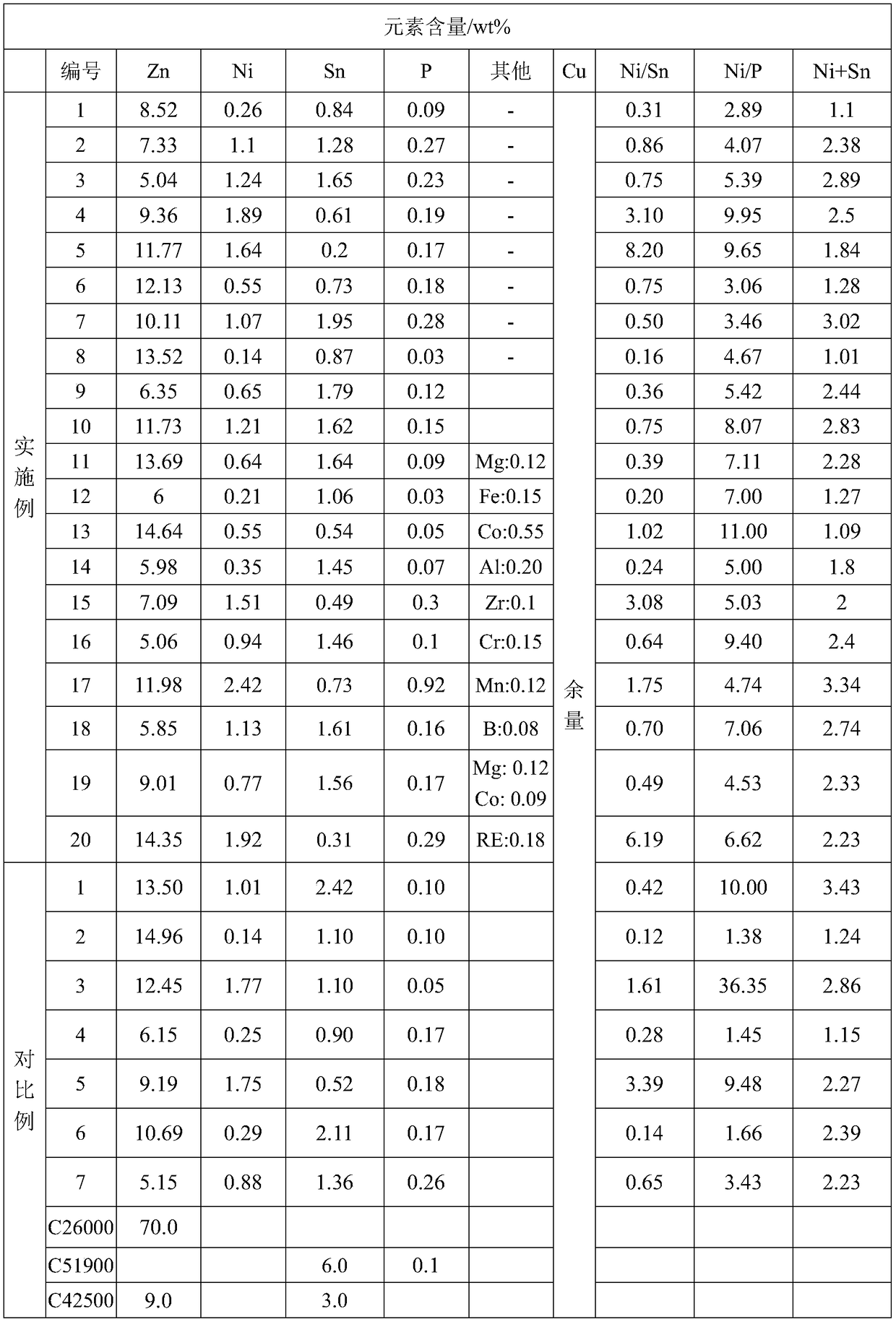

[0092] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0093] According to the copper alloy ingredients shown in each example in Table 1, semi-continuous casting was used for smelting at 1120°C-1200°C to produce an ingot with a specification of 440mm×250mm. After the above ingot was kept at 850° C. for 5 hours, it was hot-rolled to have a plate thickness of 16.5 mm. Then, due to the descaling of the surface, it is necessary to implement milling. After the hot-rolled plate and the lower milled surface are 0.5-1.0mm, the thickness of the hot-rolled plate reaches 15mm; after that, a plate with a thickness of 2mm is obtained through one cold rolling; The rolled plate is heated to 440°C and kept for 8 hours for the first aging. Then, the plate after the first aging is subjected to the second cold rolling, and the cold rolling is to 0.35 mm, and then the second aging treatment is carried out at 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com