Domestic tetrachloroethylene dry cleaning machine

A technology of tetrachloroethylene and dry cleaning machine, which is applied to household appliances, dry cleaning equipment, applications, etc., can solve the problems of reduced cleaning efficiency, lack of decontamination, clothing deformation, etc., to reduce cleaning intensity, save energy, and ensure no damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

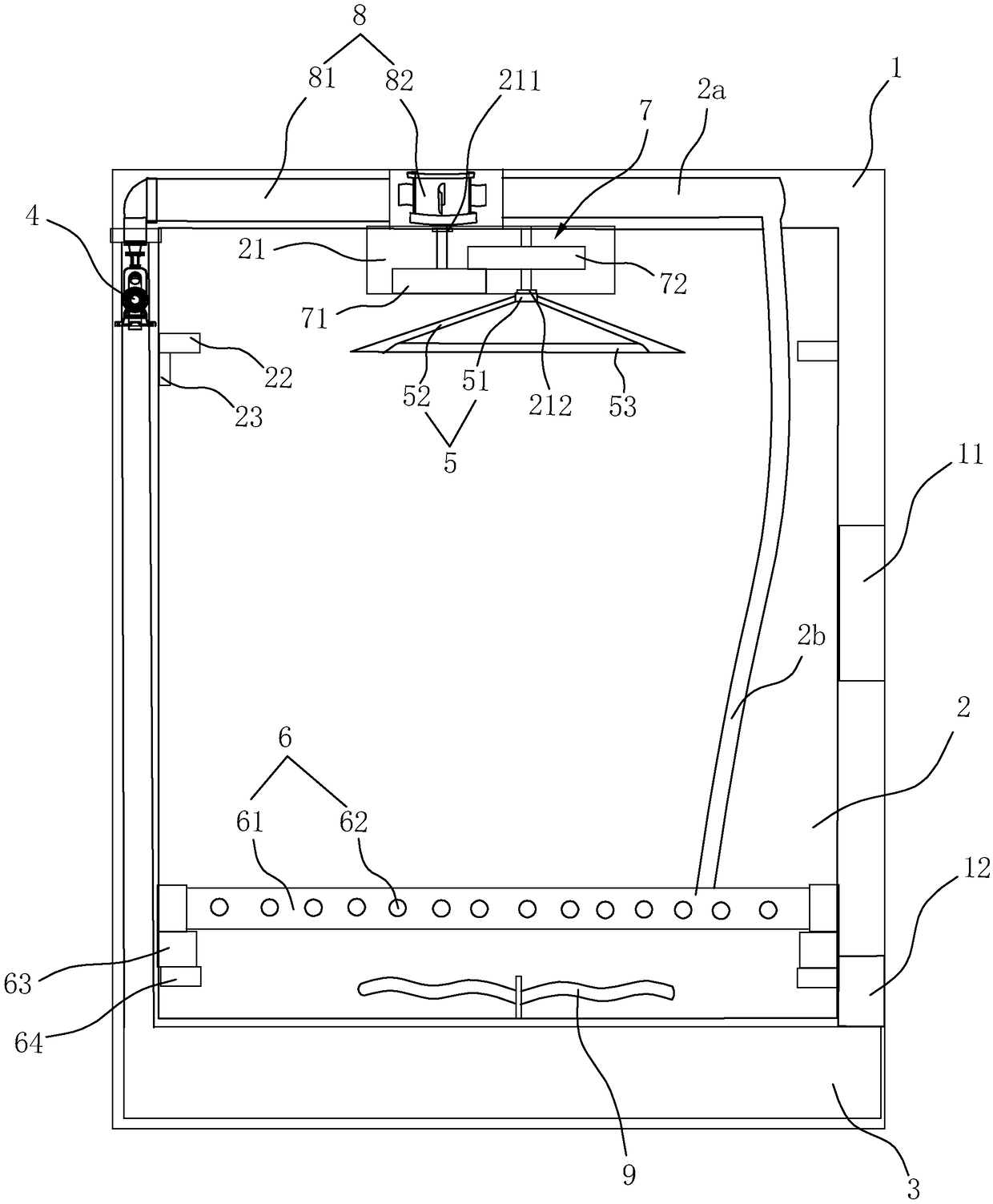

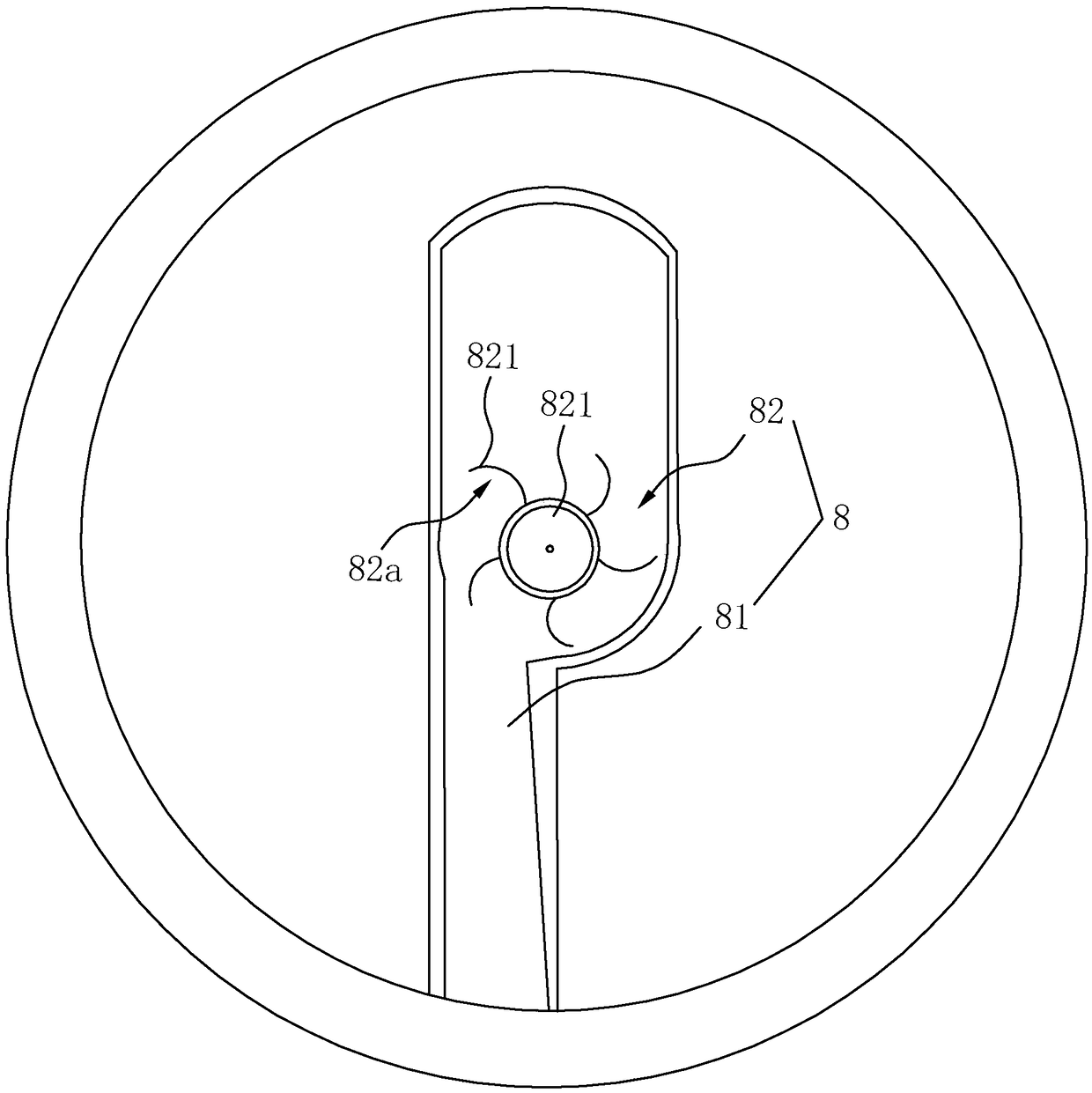

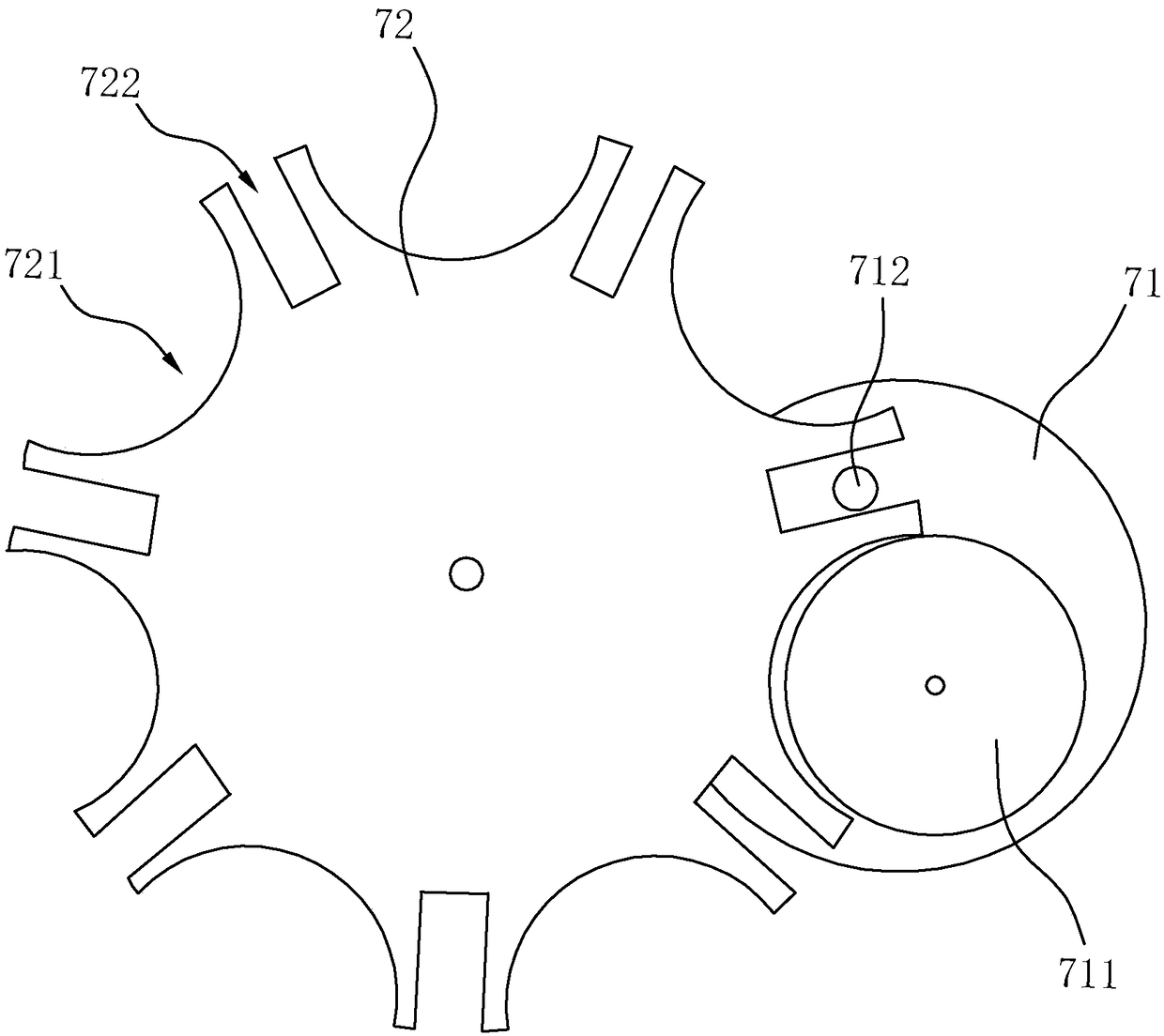

[0020] Such as Figure 1 ~ Figure 3 As shown, in this embodiment, the household perchlorethylene dry cleaning machine includes a casing 1 and a cleaning bucket 2 arranged in the casing 1, the bottom of the cleaning bucket 2 is provided with a liquid storage chamber 3 for storing dry cleaning solvent, and the cleaning bucket 2 is provided with a liquid channel 2a communicating with the cleaning bucket 2, and the liquid storage chamber 3 is communicated with the liquid channel 2a through the circulation pump 4. The liquid channel 2a is provided with a guide structure 8, the guide structure 8 has a pressurized channel 81, the width of the pressurized channel 81 gradually decreases along the direction of liquid flow, so that the flow rate of the liquid flowing through the pressurized channel 8 will be accelerated, Equivalent to directly pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com