Textile size recycling method

A technology of textile pulp and pulp, applied in textile and papermaking, fiber types, dry cleaning fiber products, etc., can solve the problems of low efficiency and the introduction of many impurities in the desizing solution, so as to improve the success rate of recovery and reduce the amount of impurities introduced. , the effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

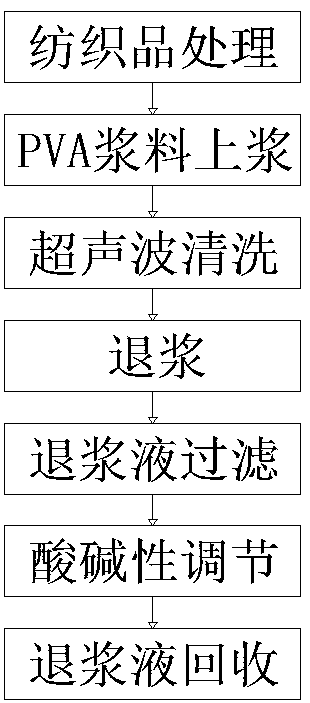

[0024] Embodiment 1, with reference to Figure 1-2 , a method for reusing textile pulp, comprising the following steps:

[0025] S1: Textile treatment, cleaning the floating dust on the surface of textile raw materials, and drying the textile raw materials;

[0026] S2: PVA size sizing, immersing textile raw materials into PVA size, performing sizing treatment, and then completing drying and weaving to obtain fabric A;

[0027] S3: Ultrasonic cleaning, put the fabric A into the ultrasonic cleaning pool, and add an appropriate amount of pure water to the ultrasonic cleaning pool, and control the ultrasonic cleaning pool for low-frequency cleaning;

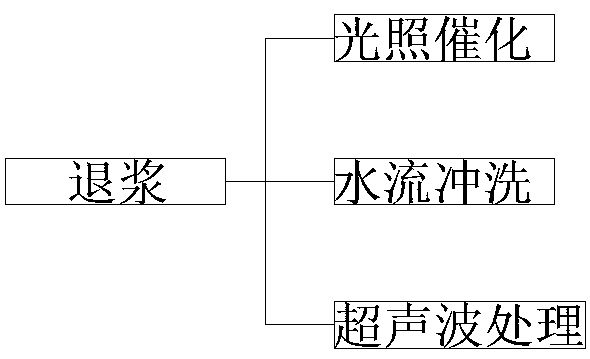

[0028] S4: Desizing, desizing the ultrasonically cleaned fabric A to obtain desizing liquid and fabric B;

[0029] S5: Filtration of the desizing liquid, putting the desizing liquid into the suction filtration equipment for suction filtration, and injecting an appropriate amount of pure water to wash the waste residue;

[0030] S...

Embodiment 2

[0033] Embodiment 2, with reference to Figure 1-2 , a method for reusing textile pulp, comprising the following steps:

[0034] S1: Textile treatment, cleaning the floating dust on the surface of textile raw materials, and drying the textile raw materials;

[0035] S2: PVA size sizing, immersing textile raw materials into PVA size, performing sizing treatment, and then completing drying and weaving to obtain fabric A;

[0036] S3: Ultrasonic cleaning, put the fabric A into the ultrasonic cleaning pool, and add an appropriate amount of pure water to the ultrasonic cleaning pool, and control the ultrasonic cleaning pool for low-frequency cleaning;

[0037] S4: Desizing, desizing the ultrasonically cleaned fabric A to obtain desizing liquid and fabric B;

[0038] S5: Filtration of the desizing liquid, putting the desizing liquid into the suction filtration equipment for suction filtration, and injecting an appropriate amount of pure water to wash the waste residue;

[0039] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com