Bridge reinforcing method and device

A technology for strengthening devices and bridges, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of being easily affected by the external environment, increasing the size and weight of components, and high cost of the outsourcing steel method, so as to improve corrosion resistance. As well as force capacity, high tensile strength and fatigue resistance, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper", "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

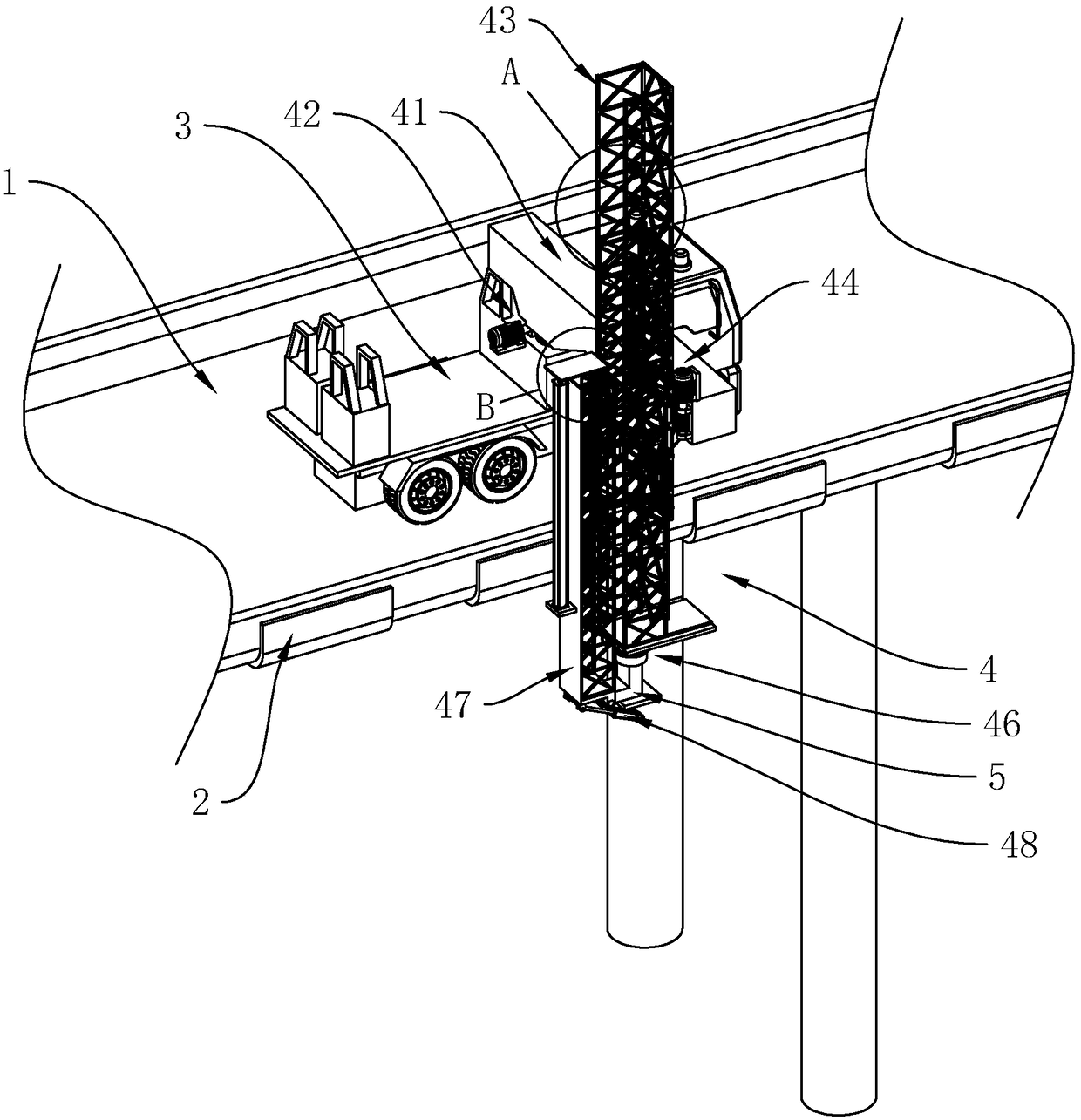

[0041] Such as figure 1 As shown, a bridge reinforcement device is used to reinforce the bridge slab 1, including carbon fiber cloth 2 fixed at the bottom of the bridge slab 1, a crane 3 arranged at the top of the bridge slab 1, installed on the crane 3 and extended to the bridge slab 1. The standing component 4 at the bottom, through which the operator can fix and bond the carbon fiber cloth 2 to the bottom of the bridge plate 1 to reinforce the bridge plate 1.

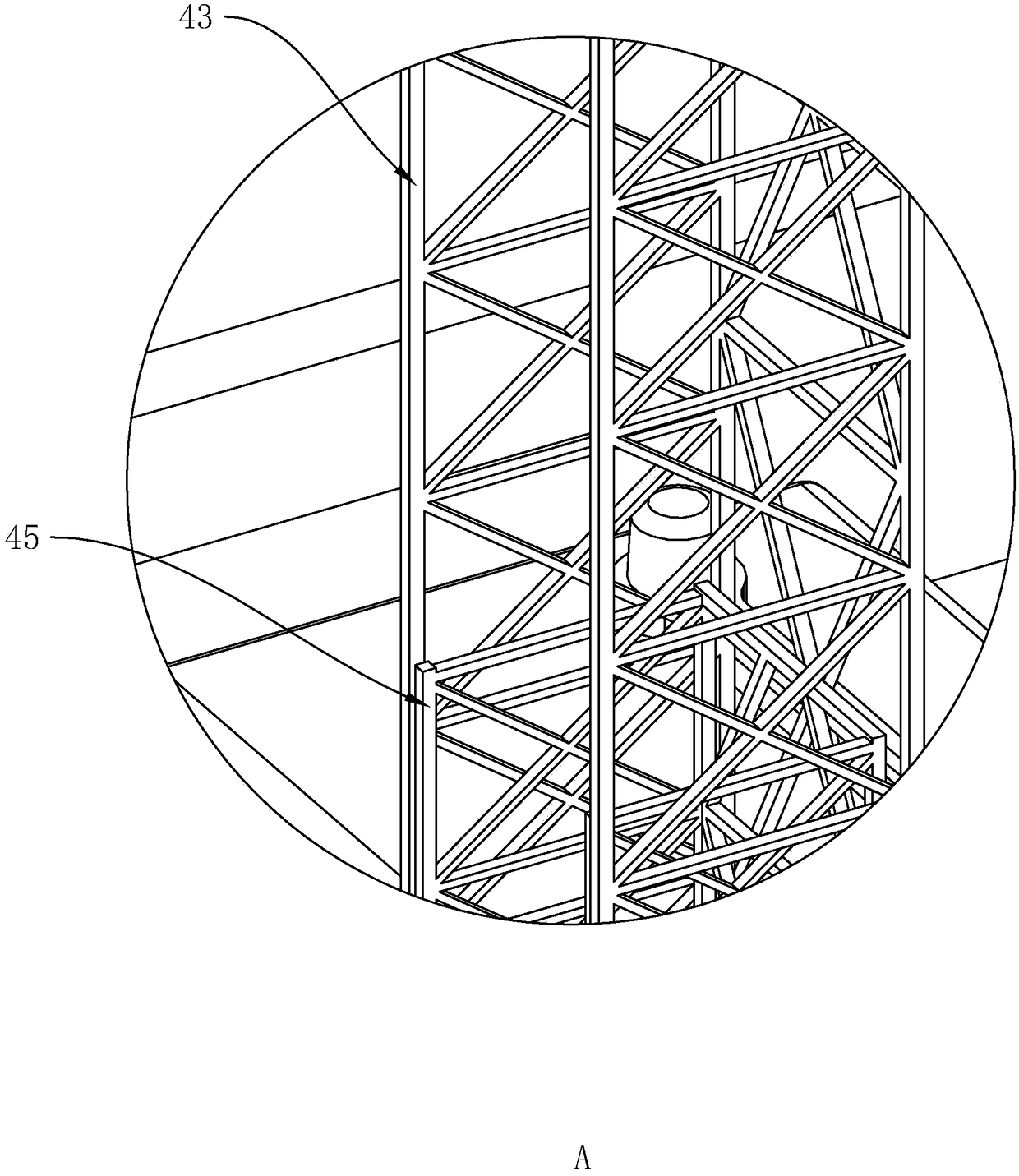

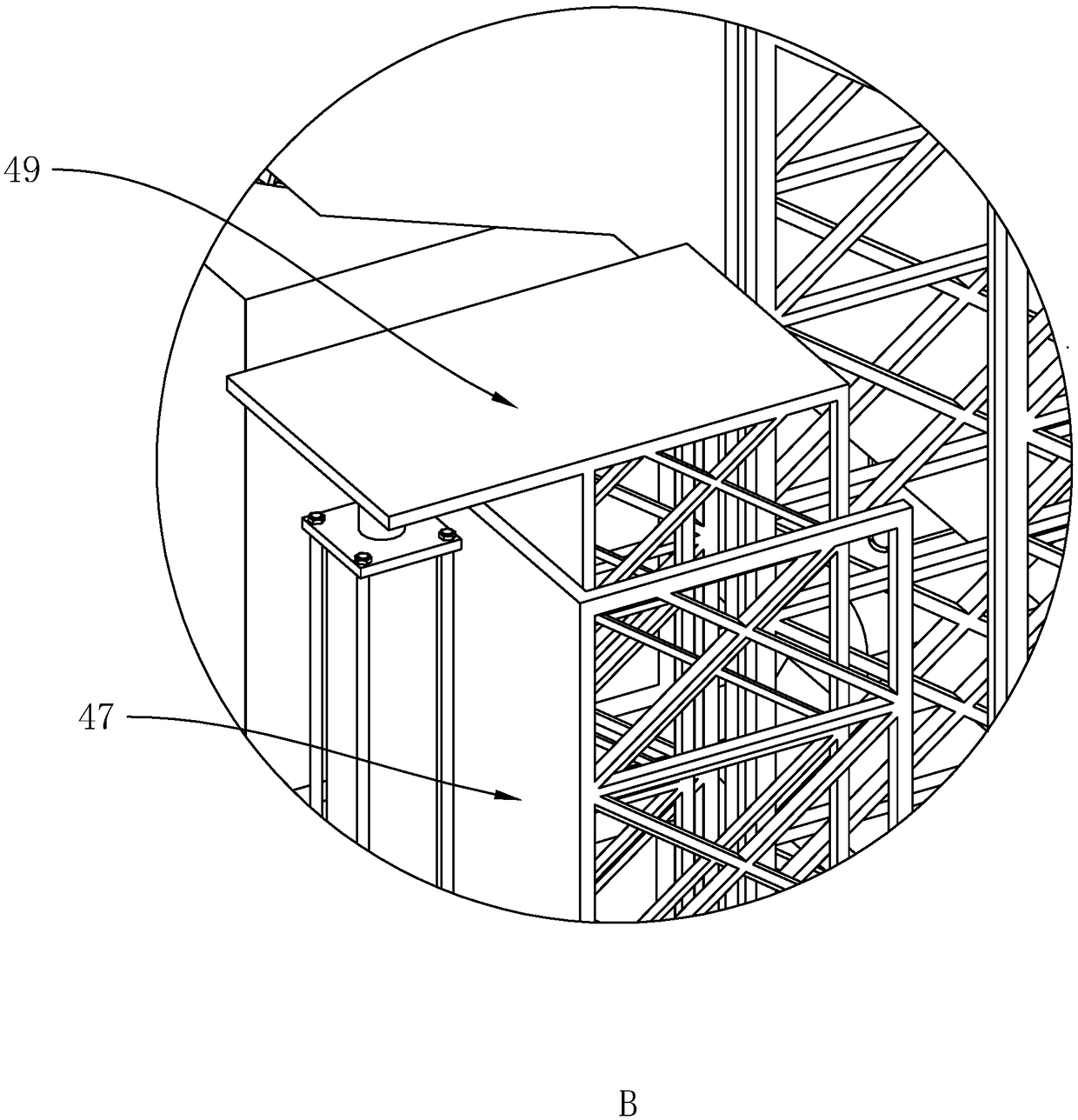

[0042] Such as figure 1The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com