Elevator traction machine absorber based on metal rubber

A technology of elevator traction machine and metal rubber, which is applied in the field of elevators, can solve the problems of elastic materials that are difficult to work stably for a long time, and achieve the effects of long fatigue aging life, high system vibration isolation rate, and taking into account the limit function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

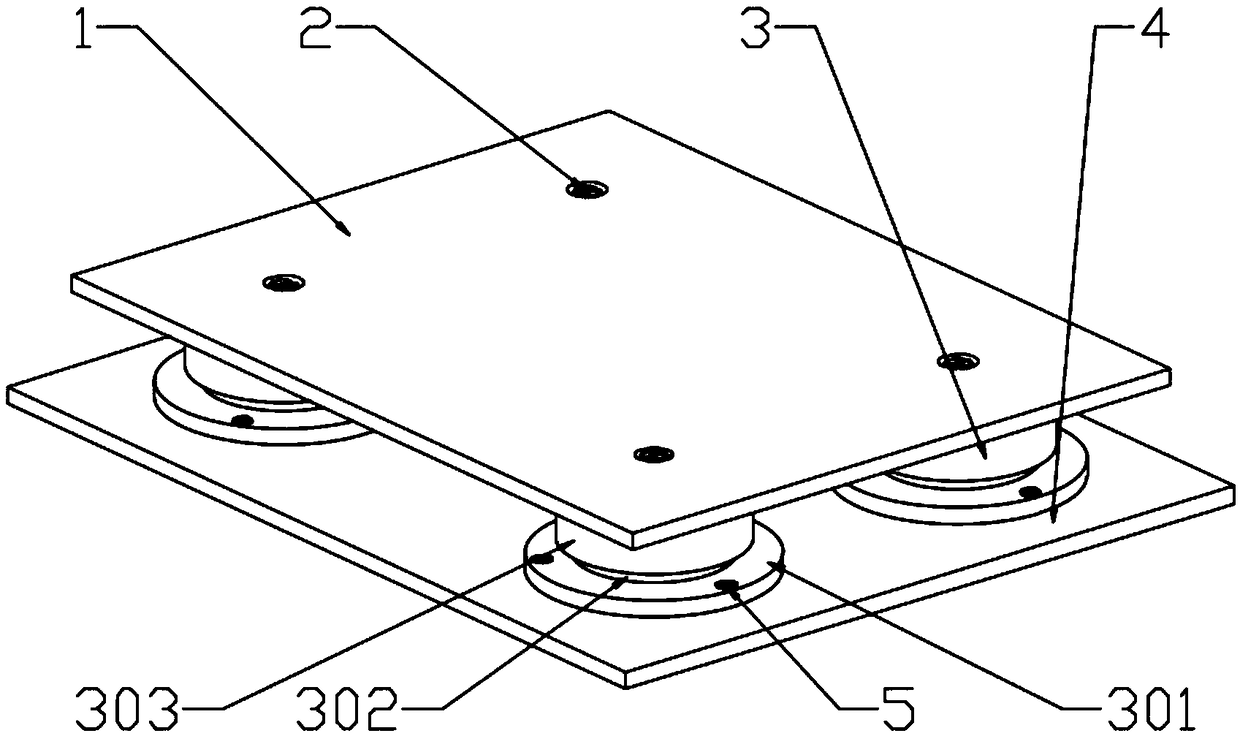

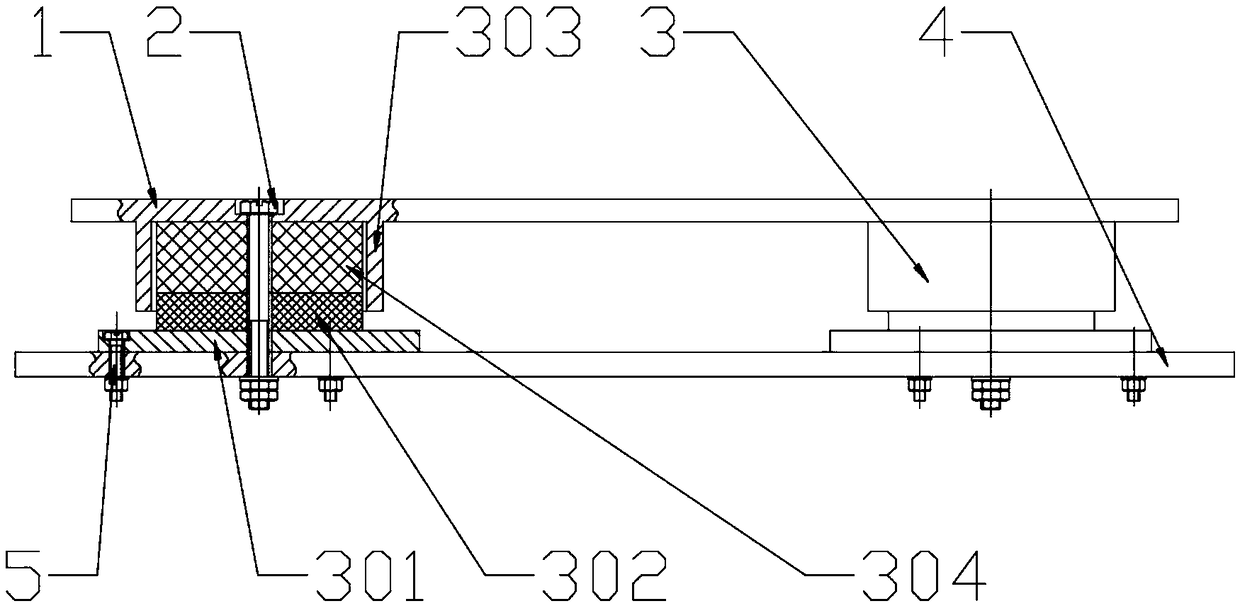

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] according to figure 1 , figure 2 As shown, the present invention provides an embodiment: a metal rubber-based elevator traction machine shock absorber, including a load-bearing panel 1 for carrying the elevator traction machine, characterized in that: the upper side of the load-bearing panel 1 The four corners are all provided with a first counterbore, so that the inner slotted bolt can pass through the first counterbore for tightening, and a damper foot 3 is welded below the corresponding position of the first counterbore, and the damper foot 3 includes Machine foot base 301 and metal sleeve 303, a through hole (not shown) is provided in the middle of the machine foot base 301, and the metal sleeve 303 is fixed to the machine foot base 301 through the through hole, so that the metal sleeve The barrel 303 and the machine foot base 301 can be fixed, and the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com