Complicated spool arrangement fixing device in wall, wall body structure and construction method of wall body structure

A technology of fixing device and wall structure, applied in the direction of walls, pipe supports, building components, etc., can solve the problems of dense and cluttered walls, difficult maintenance, and different sizes of lines and pipes, so as to achieve convenient and safe use and ensure safety. , the effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

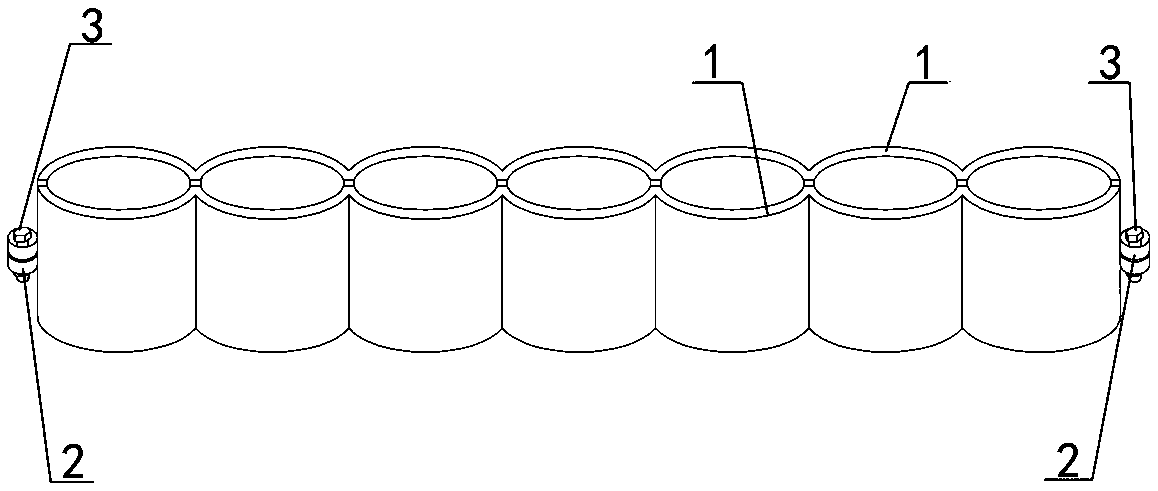

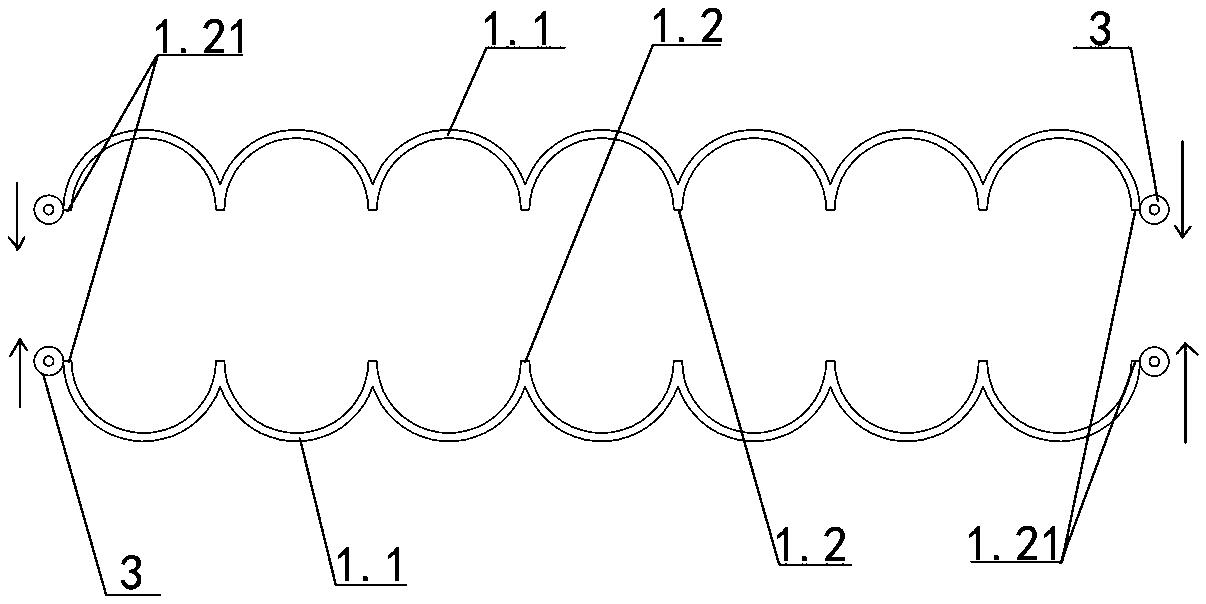

[0035] Embodiment one sees Figure 1-4 As shown in the figure, a complex wire pipe arrangement and fixing device in the wall includes a wire pipe sleeve and a locking assembly. The half-pipe sheet 1 that mirrors the sheet structure and is used in combination, the half-pipe sheet is made of stainless steel pipe, the half-pipe sheet includes a row of continuous outward bending, at least two semicircular casings 1.1, each semicircular casing has two Half-segment splicing seam 1.2, a half-segment splicing seam 1.2 is shared between adjacent semi-circular casings, each half-segment splicing seam of the front and rear two half-segments is spliced together, and the corresponding semi-circular casing 1.1 is spliced to form Complete round casing. The pipe diameters of the circular sleeves are the same.

[0036] There are two groups of locking components, which are respectively fixedly connected to the outermost ends of the line pipe row sleeves, and each group includes two thread...

Embodiment 2

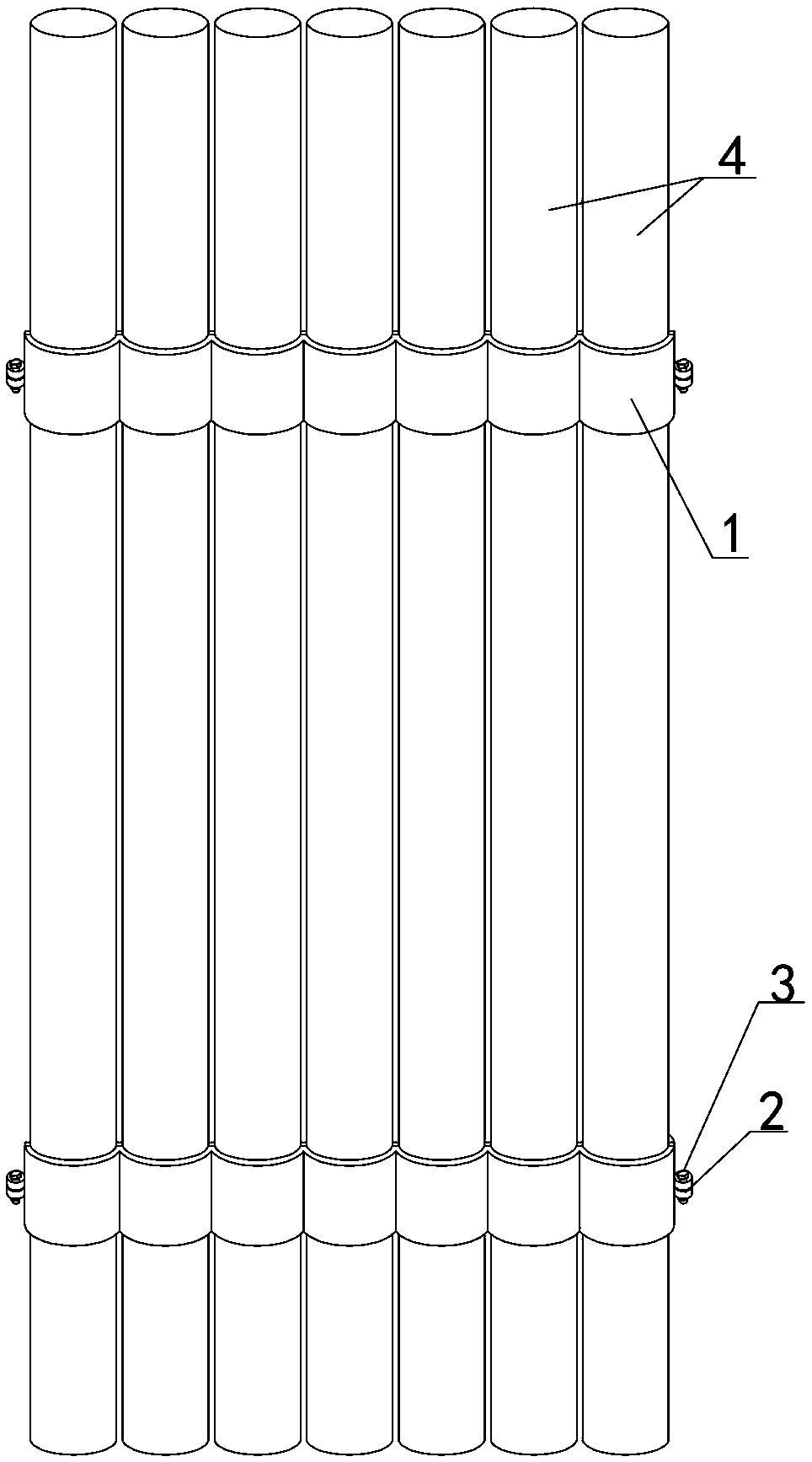

[0041] Embodiment two see Figure 6-7 As shown, the height of the circular casing is 5cm-10cm. The difference from Embodiment 1 is that the pipe diameters of the circular sleeves are different.

[0042] There are seven circular casings in this embodiment, the diameters of the circular casings from left to right are 12mm, 14mm, 10mm, 12mm, 12mm, 12mm and 12mm, and the wall thickness of the half-pipe is 5mm. The diameter of the locking bolt mentioned above is 10mm.

[0043] see Figure 8 As shown, a wall structure is disclosed by taking the complex wiring and pipe arrangement and fixing device in the wall as an example. A group of wire pipes 4 with different pipe diameters fixed in the wire pipe row casing, the complex wire pipe arrangement and fixing device in the wall is provided at least one on the upper part and the lower part of the wire pipe 4 respectively, and the complex wire pipe arrangement in the wall is fixed Both the device and the line pipe 4 are embedded in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com