Yellow tea of new technology, and production method thereof

A new process and technology for yellow tea, applied in the field of new process yellow tea and its production, can solve the problems affecting the safety and quality of tea, increase the production scale of processing, increase the processing cost, etc. Degradation, soup color yellow bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

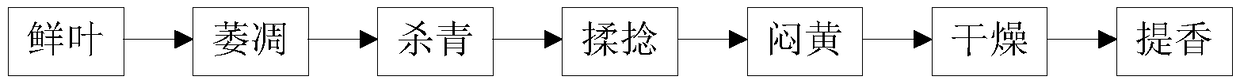

[0024] A method for preparing sweet-flavored (crispy rice-flavored) type yellow tea of a new process, the steps are as follows:

[0025] 1. Fresh leaf standard: The tea tree of Fuding Dabai variety has one bud and one leaf, and one bud and two leaves. It requires no damage, no purple buds, and no pests and diseases.

[0026] 2. Withering: spread the picked fresh tea leaves on the bamboo plaque in time, with a thickness of 2.5cm, the temperature of the withering room is 20°C, the humidity is about 65%, and the withering time is about 12 hours. The moderate standard of withering is: the water content of fresh leaves is about 65%, the leaf quality is soft, and the green air is scattered.

[0027] 3. Finishing: Use the 6CST-40 type tea drum finishing machine, and set the finishing temperature at about 240°C. The finishing needs to be done evenly and thoroughly, and no reddening phenomenon can occur; generally, the moisture content of the leaves is about 50%, and the leaves can b...

Embodiment 2

[0033] A method for processing sweet and fragrant (crispy rice) type yellow tea of new technology, the steps are as follows:

[0034] 1. Fresh leaf standard: The tea tree of Fuding Dabai variety has one bud and one leaf, and one bud and two leaves. It requires no damage, no purple buds, and no pests and diseases.

[0035] 2. Withering: Spread the picked fresh tea leaves on the bamboo plaque in time, with a thickness of 3 cm. The temperature of the withering room is 22°C, the humidity is about 70%, and the withering time is about 14 hours. The moderate standard of withering is: the water content of fresh leaves is about 65%, the leaf quality is soft, and the green air is scattered.

[0036] 3. Finishing: Use the 6CST-40 type tea drum finishing machine, set the finishing temperature at about 260°C, the finishing needs to be uniform and thorough, and reddening cannot occur; when the moisture content of the leaves is about 53%, the leaves can be kneaded into a ball, slightly It...

Embodiment 3

[0042] 1. Fresh leaf standard: The tea tree of Fuding Dabai variety has one bud and one leaf, and one bud and two leaves. It requires no damage, no purple buds, and no pests and diseases.

[0043] 2. Withering: Spread the picked fresh tea leaves on the bamboo plaque in time, with a thickness of 3.5cm. The temperature of the withering room is 25°C, the humidity is about 80%, and the withering time is about 16 hours. The moderate standard of withering is: the water content of fresh leaves is about 65%, the leaf quality is soft, and the green air is scattered.

[0044] 3. Finishing: Use the 6CST-40 type tea drum finishing machine, set the finishing temperature at about 300°C, the finishing needs to be uniform and thorough, and reddening cannot occur; until the moisture content of the leaves is about 55%, the leaves can be rolled into a ball, slightly It is elastic, the stem is not easy to break, the grass smell disappears, and the floral fragrance is moderate.

[0045] 4. Kneadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com