A large diameter flange drilling device

A drilling device and large-diameter technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as the inability to meet the drilling requirements of flange workpieces with a diameter greater than five meters, and achieve The effect of widening the processing diameter range, flexible and convenient use, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

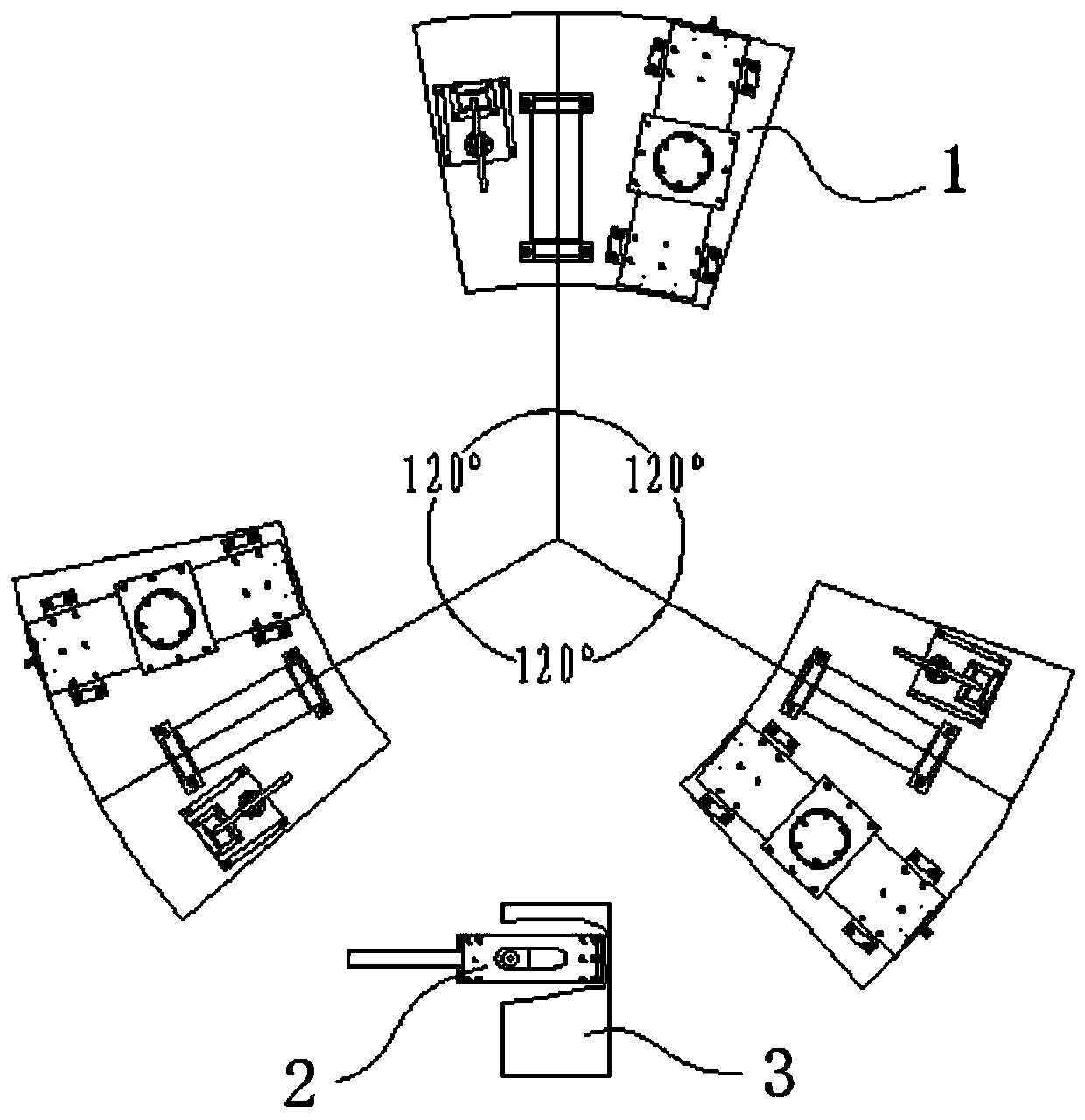

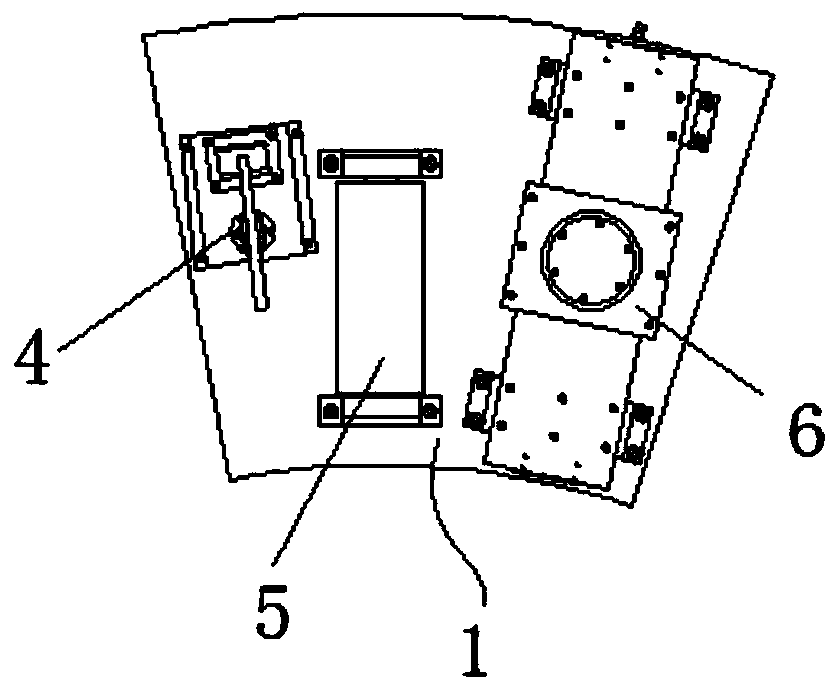

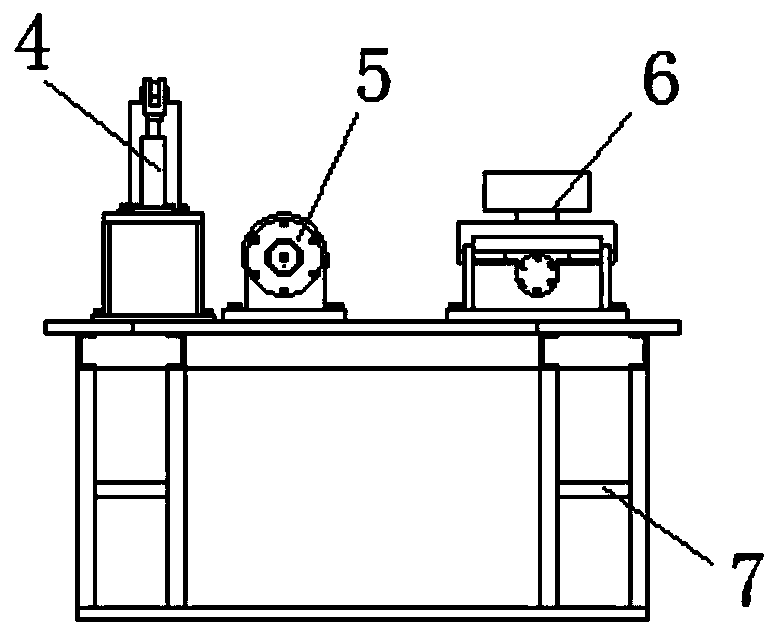

[0036] Such as Figure 1-15 As shown, the present invention comprises a transposition positioning mechanism 2, a drilling device 3, a drilling mold 10 and a plurality of supporting workbenches 1, each supporting workbench 1 is evenly distributed along the circumferential direction, and the transposition positioning mechanism 2 and the drill The hole device 3 is arranged between two adjacent supporting tables 1, and the indexing mechanism 2 is installed on the upper side of the drilling device 3, and the supporting table 1 is provided with a clamping mechanism 4, The horizontal idler 5 and the vertical roller mechanism 6 are provided with a moving block 206 on the indexing positioning mechanism 2, and a liftable positioning pin 202 is arranged inside the moving block 206. When the mechanism is working, the workpiece 8 and the drilling mold 10 are connected an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com