C-shaped steel machining equipment for steel structures

A technology for processing equipment and C-shaped steel, applied in metal processing equipment, shearing machine equipment, metal sawing equipment, etc., can solve the problems of high labor intensity, tool damage, long time consumption, etc., to reduce labor intensity and improve work. Efficiency, the effect of incision leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

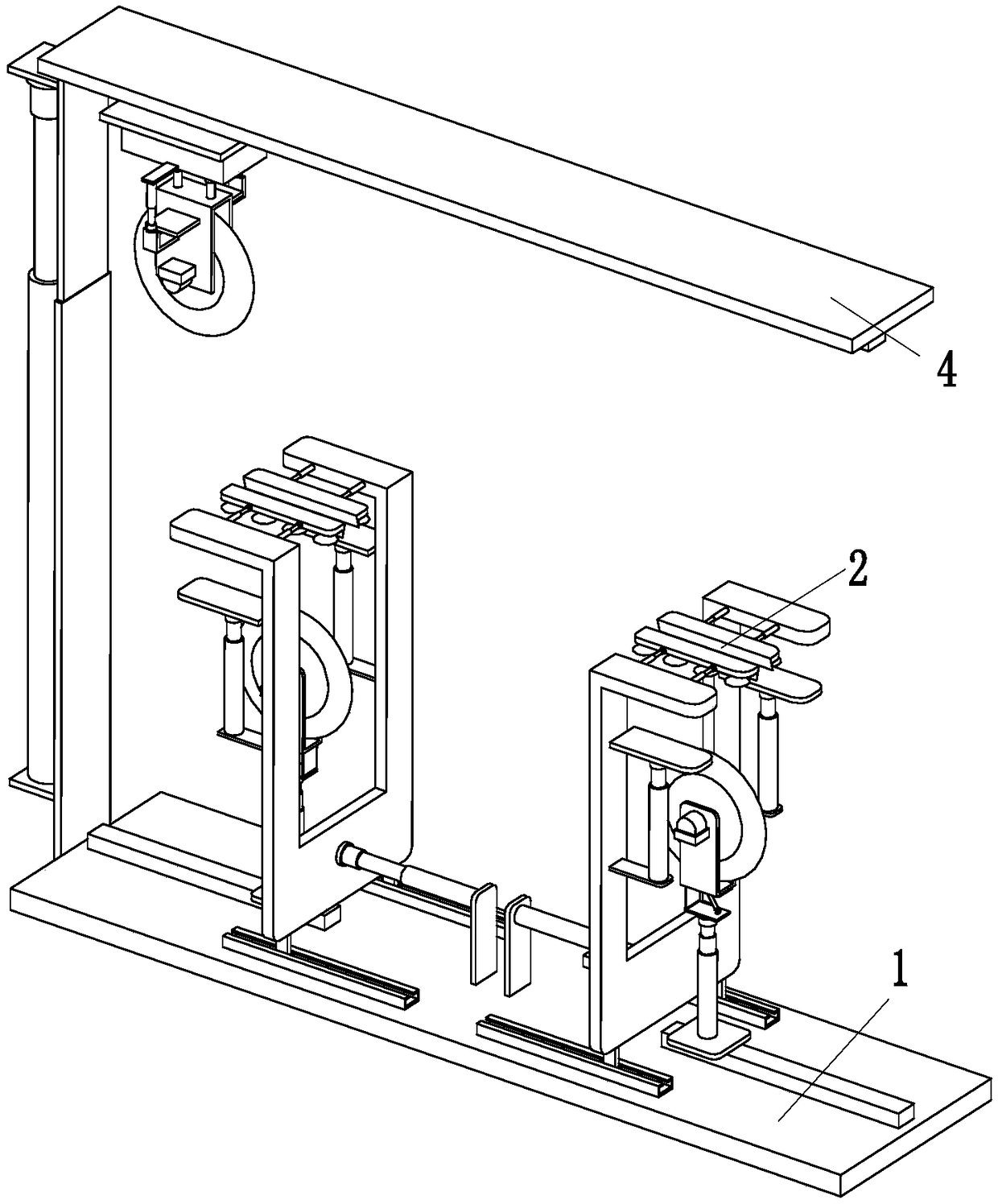

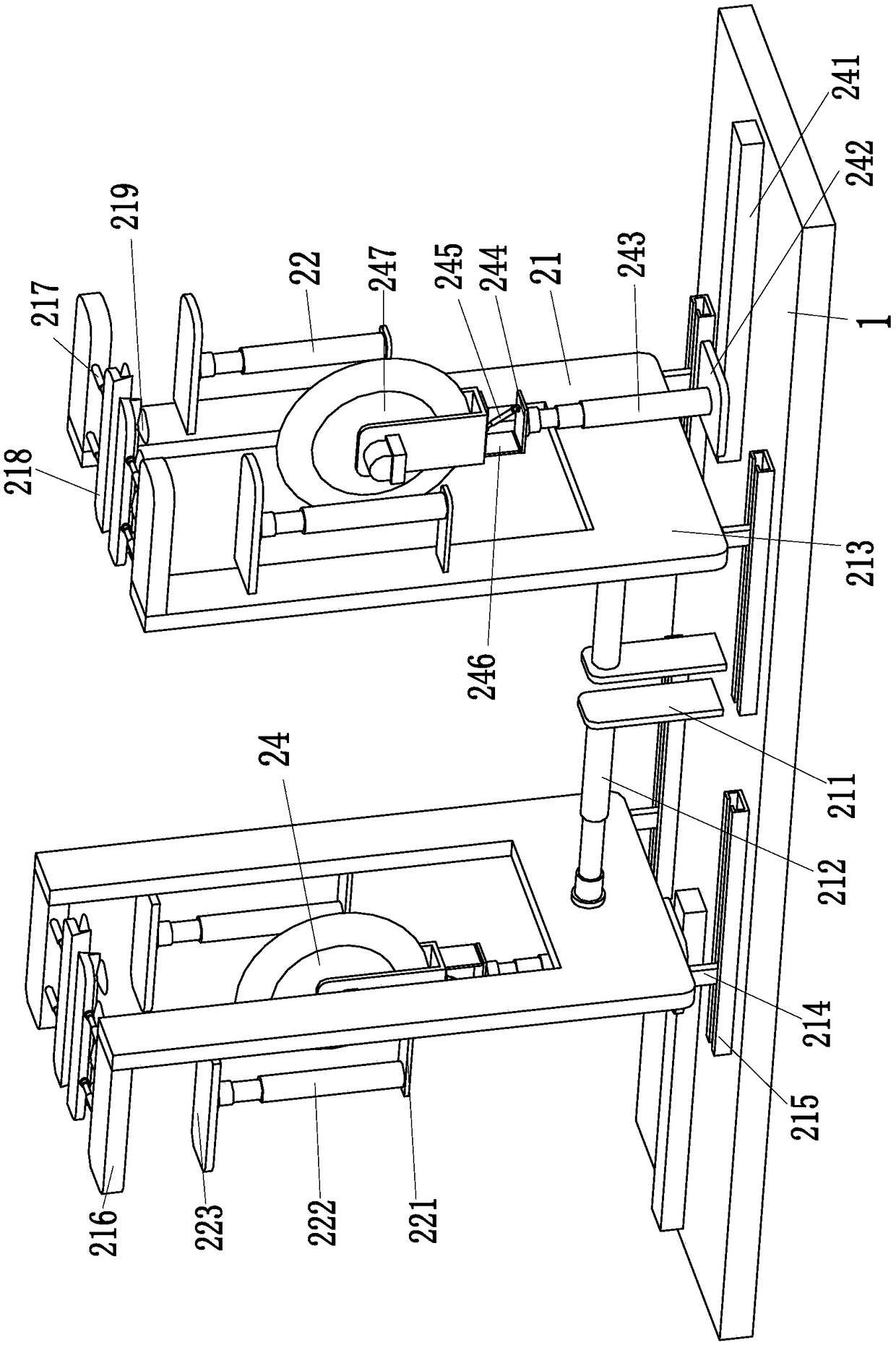

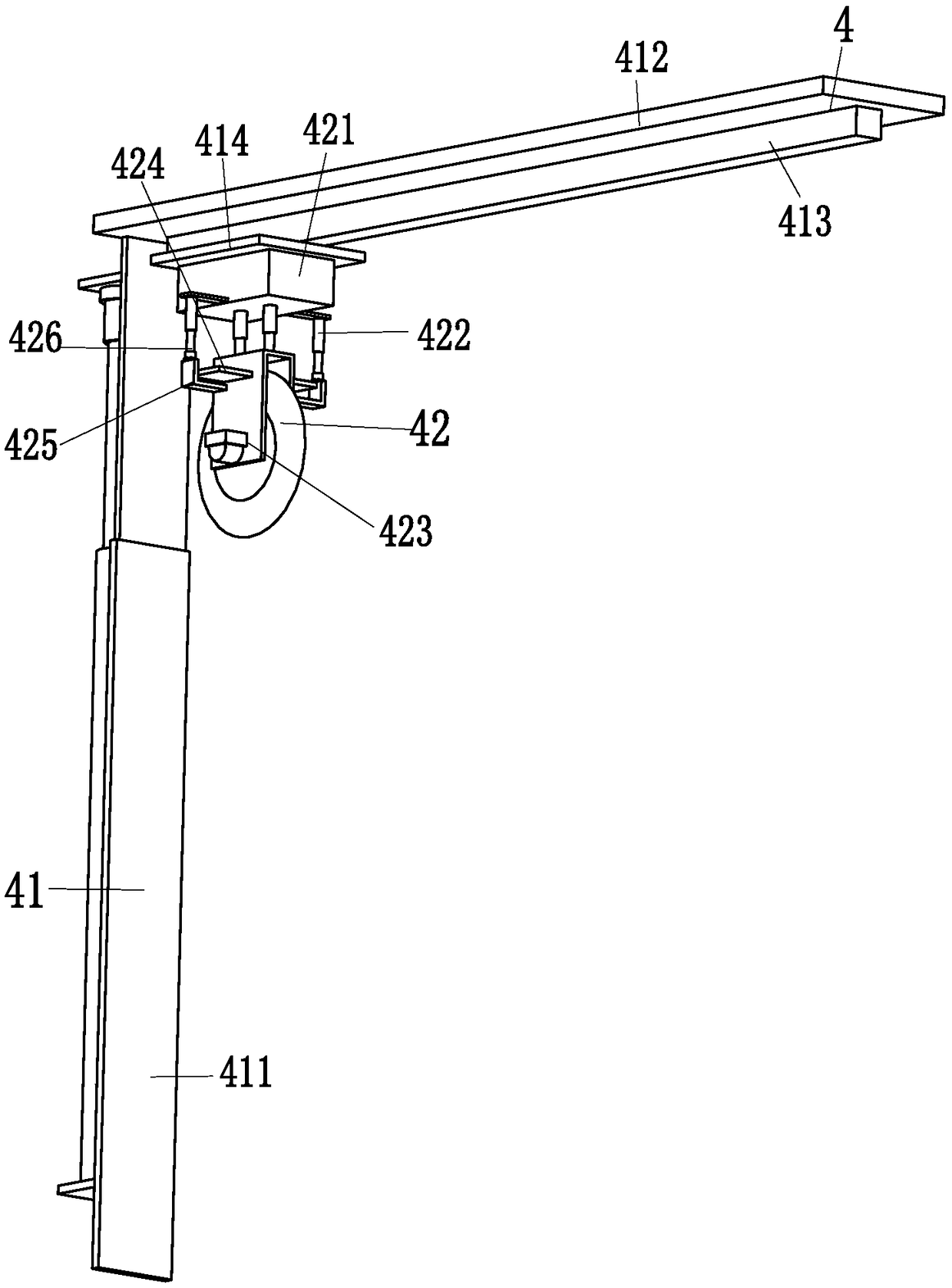

[0023] Such as Figure 1 to Figure 4 As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a C-shaped steel processing equipment for steel structure, including a main board 1, two compacting and cutting devices 2 and an upper end cutting device 4, and the middle part of the upper end of the main board 1 is installed Two compacting and cutting devices 2 are arranged, and an upper end cutting device 4 is installed on the left end of the main board 1 .

[0024]The compacting and cutting device 2 includes a lower end compacting m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap