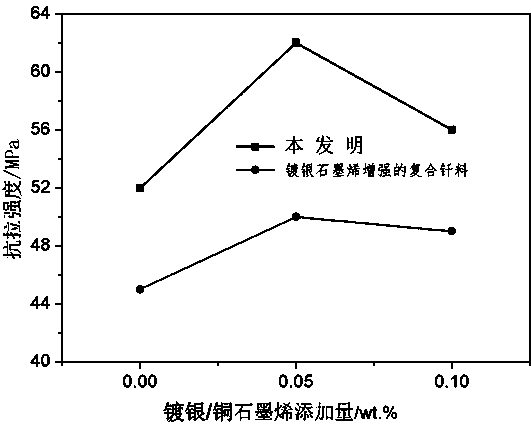

Pyrolysis method synthesis strong combination-based copper coated graphene reinforced high-strength Sn-Ag-Cu-RE series composite brazing filler metal and preparation method

A sn-ag-cu-re, copper-plated graphene technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem of less wettability than nickel, improve performance, inhibit spontaneous agglomeration, reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of a kind of pyrolysis synthesis of the high-strength Sn-Ag-Cu-RE composite brazing filler metal that is strongly combined with copper-plated graphene reinforced by the present invention comprises two major steps:

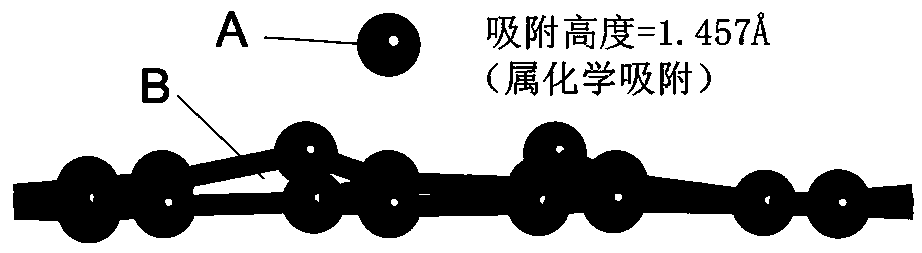

[0041] Step (1) Prepare copper-coated graphene by pyrolysis method to obtain copper-coated graphene strengthening phase;

[0042]Step (2) Mix the copper-coated graphene-reinforced phase obtained in step (1) with Sn-Ag-Cu-RE lead-free solder and prepare copper-coated graphene-reinforced high-strength Sn- Ag-Cu-RE composite solder.

[0043] The above step (1) specifically includes the following steps:

[0044] Step 1.1, place the pre-weighed graphene nanosheets in a high-energy ball mill for high-energy ball milling at a speed of 500r / min, and a ball milling time of 3 hours. After the ball milling, take it out for use;

[0045] Step 1.2. Mechanically mix the ball-milled GNSs with copper acetate (Cu(CH3COO)2•H2O) powder to obtain a unif...

Embodiment 1

[0056] Step (1): preparing copper-coated graphene by pyrolysis method to obtain a copper-coated graphene strengthening phase;

[0057] Step 1.1. Place the pre-weighed graphene nanosheets in the XQM-0.4L planetary ball mill for high-energy ball milling with a rotation speed of 500r / min and a ball milling time of 3 hours. After the ball milling, take it out for use;

[0058] Step 1.2. Mechanically mix the ball-milled GNSs with copper acetate (Cu(CH3COO)2•H2O) powder to obtain a uniformly colored mixed powder. Set the loading ratio to 10mol.%, that is, the amount of copper atomic substances is the amount of carbon atomic substances 1 / 10 of;

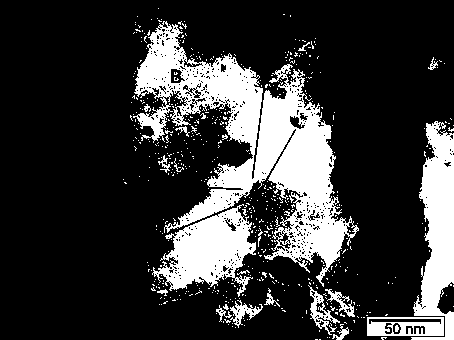

[0059] Step 1.3, place the uniformly mixed powder in a tube furnace with nitrogen, keep it warm at 500°C for 3 hours, and then cool to room temperature with the furnace to obtain copper-coated graphene.

Embodiment 2

[0061] Step (1): preparing copper-coated graphene by pyrolysis method to obtain a copper-coated graphene strengthening phase;

[0062] Step 1.1. Place the pre-weighed graphene nanosheets in the XQM-0.4L planetary ball mill for high-energy ball milling with a rotation speed of 500r / min and a ball milling time of 3 hours. After the ball milling, take it out for use;

[0063] Step 1.2. Mechanically mix the ball-milled GNSs with copper acetate (Cu(CH3COO)2•H2O) powder to obtain a uniformly colored mixed powder. Set the loading ratio to 10mol.%, that is, the amount of copper atomic substances is the amount of carbon atomic substances 1 / 10 of;

[0064] Step 1.3, place the uniformly mixed mixed powder in a tube furnace with nitrogen, keep it warm at 450°C for 5h, and then cool to room temperature with the furnace to obtain copper-coated graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com