Recyclable polyester material with main chain containing active double bonds as well as preparation method and application thereof

A polyester material, a lively technology, applied in the field of recyclable polyester materials, can solve the problems of non-recyclable and difficult to obtain, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

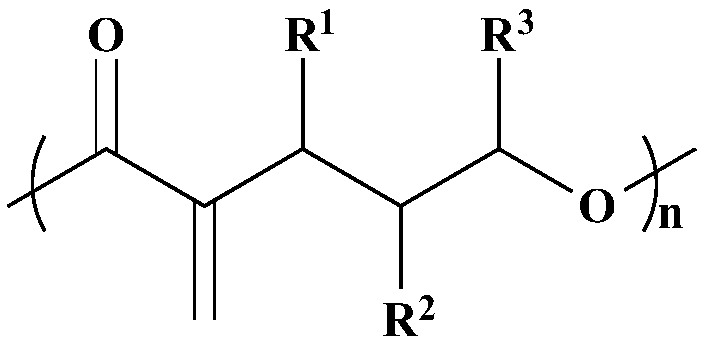

Method used

Image

Examples

Embodiment 1

[0028]

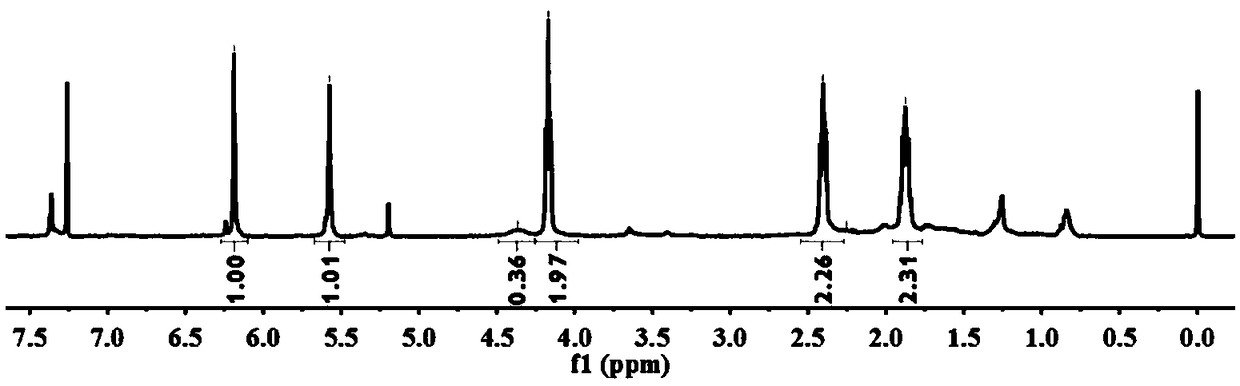

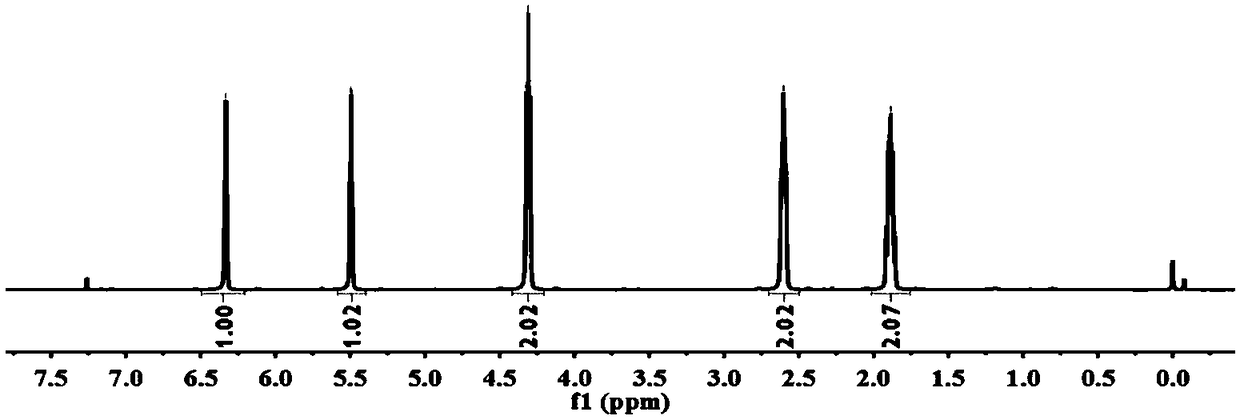

[0029] At 20°C, add 10 μmol of catalyst 1 and 5 mL of toluene to a pre-dried 25 mL round-bottomed flask, then add 20 μmol of benzyl alcohol, stir for 5 minutes, add 1 mmol of α-methylene-β-valerolactone, and place under nitrogen protection Stir for 2 hours under certain conditions, add 1ml of hydrochloric acid acidified methanol to terminate the polymerization reaction, add 100mL of n-hexane, filter to obtain the polymer, wash with 30mL of n-hexane each time, wash 3 times, and dry in a vacuum oven to constant weight , to obtain 0.2 g of white powder, the average molecular weight of the polymer measured by gel chromatography is 8000, the molecular weight distribution is 1.10, 100% of the double bonds in the NMR determination polymer are retained, and the DSC test shows that the melting point of the polymer is 72 ° C.

Embodiment 2

[0031] In the same experimental apparatus used in Example 1, under the same conditions, only the temperature was reduced to -30 ° C for 3 hours to obtain 0.21 grams of polymer, and the average molecular weight of the polymer measured by gel chromatography was 12000, and the molecular weight distribution was 1.11. 100% of the double bonds in the polymer are retained as determined by NMR, and the melting point of the polymer is 73° C. according to the DSC test.

Embodiment 3

[0033] In the same experimental apparatus used in Example 1, under the same conditions, only the amount of benzyl alcohol was changed to 50 μmol, after 2 hours, 0.19 grams of polymer was obtained, and the average molecular weight of the polymer was determined by gel chromatography 6000, and the molecular weight distribution was 1.15 100% of the double bonds in the polymer are retained as determined by NMR, and the melting point of the polymer is 72° C. according to the DSC test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com