Preparation method of neodymium-doped carbon quantum dot composite material with hemp being carbon source

A technology of carbon quantum dots and composite materials, which is applied in the field of nano-luminescent material preparation, can solve problems such as environmental pollution and hemp resource waste, and achieve the effects of good biocompatibility, small size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

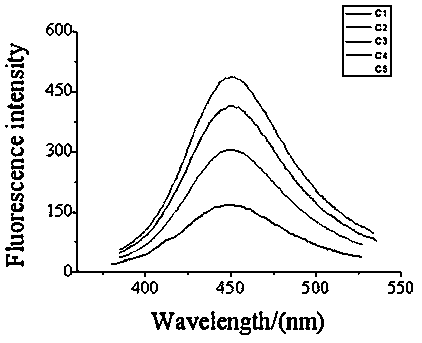

Image

Examples

Embodiment 1

[0022] (1) A solution configuration: In the reactor, add deionized water: 97 mL, neodymium chloride: 3g, heat and stir to dissolve, cool to room temperature, stir evenly, and obtain A solution;

[0023] (2) B solution configuration: In the reactor, add methanol: 120mL, quercetin: 5g20mL, heat and stir to dissolve, cool to room temperature, stir evenly, and obtain B solution;

[0024] (3) Preparation of quercetin neodymium complex: put 40 mL of solution B in a reactor, stir, and raise the temperature to 65±2°C, add 20 mL of solution A to solution B dropwise, and use volume Adjust the pH to 8.5 with 15% ammonia water, keep the temperature at 65±2°C, stir and react for 8 hours, a large amount of brown precipitate can be obtained, centrifuged, washed with distilled water until neutral, and then washed with methanol for 2~ 3 times. Vacuum drying obtains quercetin neodymium complex;

[0025] (4) Preparation of neodymium-doped carbon quantum dot composite material: In a reaction ke...

Embodiment 2

[0027] (1) A solution configuration: In the reactor, add deionized water: 95 mL, neodymium chloride: 5g, heat and stir to dissolve, cool to room temperature, stir evenly, and obtain A solution;

[0028] (2) B solution configuration: In the reactor, add methanol: 116mL, quercetin: 8g, heat and stir to dissolve, cool to room temperature, stir evenly, and obtain B solution;

[0029] (3) Preparation of quercetin neodymium complex: put 36 mL of solution B in a reactor, stir, and raise the temperature to 65±2°C, add 20 mL of solution A to solution B dropwise, and use volume Adjust the pH to 8.5 with 15% ammonia water, keep the temperature at 65±2°C, stir and react for 8 hours, a large amount of brown precipitate can be obtained, centrifuged, washed with distilled water until neutral, and then washed with methanol for 2~ 3 times. Vacuum drying obtains quercetin neodymium complex;

[0030] (4) Preparation of neodymium-doped carbon quantum dot composite material: In a reaction kettle...

Embodiment 3

[0032] (1) A solution configuration: In the reactor, add deionized water: 98 mL, neodymium chloride: 2g, heat and stir to dissolve, cool to room temperature, stir evenly, and obtain A solution;

[0033] (2) Solution B configuration: In the reactor, add methanol: 122mL, quercetin: 4g, heat and stir to dissolve, cool to room temperature, stir evenly, and obtain B solution;

[0034] (3) Preparation of quercetin neodymium complex: put 44 mL of solution B in a reactor, stir, and raise the temperature to 65±2°C, add 20 mL of solution A to solution B dropwise, and use volume Adjust the pH to 8.5 with 15% ammonia water, keep the temperature at 65±2°C, stir and react for 8 hours, a large amount of brown precipitate can be obtained, centrifuged, washed with distilled water until neutral, and then washed with methanol for 2~ 3 times. Vacuum drying obtains quercetin neodymium complex;

[0035] (4) Preparation of neodymium-doped carbon quantum dot composite material: In a reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com