Method for preparing multielement non-metallic-element co-doped carbon quantum dots

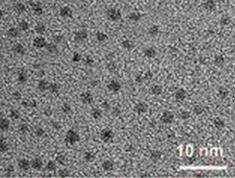

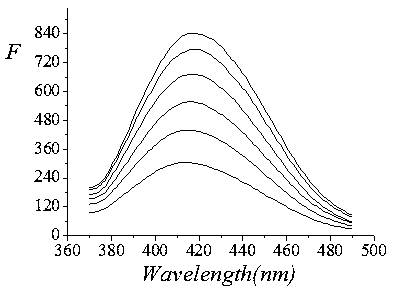

A non-metallic element, carbon quantum dot technology, applied in the field of nano-luminescent material preparation, can solve the problems of inability to accurately control the lateral size and surface chemistry, low fluorescence quantum yield of synthetic methods, unclear light-emitting mechanism, etc., to achieve quantum production. rate improvement, size uniformity, and size-dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Pretreatment of cassia seed shell powder: In the reactor, add 3.0mol / L hydrochloric acid solution: 80 mL, ammonium persulfate: 6g, dissolve, then add cassia seed shell powder: 14g, soak at room temperature for 8 hours, and then boil After cooling for 30 minutes, wash with deionized water until neutral, separate the solid and liquid, then wash with deionized water until neutral, and dry to obtain pretreated cassia husk powder;

[0022] (2) Preparation of crude multivariate non-metallic elements co-doped carbon quantum dots: In the reaction kettle, add 1-ethyl-2,3-dimethylimidazolium hexafluorophosphonium salt: 34g, 1-ethyl- 3-methylimidazole tetrafluoroborate: 34g, 1-ethyl-3-methylimidazolium bistrifluoromethanesulfonimide salt: 17g, pretreated cassia seed shell powder: 15g, stir evenly, and cover with a sealing cap , placed in an incubator at a constant temperature of 140±2°C, and reacted for 19 hours to obtain a light yellow viscous transparent liquid, which is car...

Embodiment 2

[0025] (1) Pretreatment of cassia seed shell powder: In the reactor, add 3.0mol / L hydrochloric acid solution: 79 mL, ammonium persulfate: 5g, dissolve, then add cassia seed shell powder: 16g, soak at room temperature for 8h, and then boil After cooling for 30 minutes, wash with deionized water until neutral, separate the solid and liquid, then wash with deionized water until neutral, and dry to obtain pretreated cassia husk powder;

[0026] (2) Preparation of crude multivariate non-metallic elements co-doped carbon quantum dots: In the reaction kettle, add 1-ethyl-2,3-dimethylimidazolium hexafluorophosphonium salt: 35g, 1-ethyl- 3-methylimidazole tetrafluoroborate: 36g, 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt: 19g, pretreated cassia seed shell powder: 10g, stir evenly, and cover with a sealing cap , placed in an incubator at a constant temperature of 140±2°C, and reacted for 18 hours to obtain a light yellow viscous transparent liquid, which is carbon qua...

Embodiment 3

[0029] (1) Pretreatment of cassia seed shell powder: In the reactor, add 3.0mol / L hydrochloric acid solution: 81 mL, ammonium persulfate: 4g, dissolve, then add cassia seed shell powder: 15g, soak at room temperature for 8 hours, and then boil After cooling for 30 minutes, wash with deionized water until neutral, separate the solid and liquid, then wash with deionized water until neutral, and dry to obtain pretreated cassia husk powder;

[0030] (2) Preparation of crude multivariate non-metallic elements co-doped carbon quantum dots: In the reaction kettle, add 1-ethyl-2,3-dimethylimidazolium hexafluorophosphonium salt: 37g, 1-ethyl- 3-methylimidazole tetrafluoroborate: 35g, 1-ethyl-3-methylimidazolium bistrifluoromethanesulfonimide salt: 15g, pretreated cassia seed shell powder: 10g, stir evenly, and cover with a sealing cap , placed in an incubator at a constant temperature of 140±2°C, and reacted for 20 hours to obtain a light yellow viscous transparent liquid, which is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com