Brewing process of fresh rose flower beer

A rose and beer technology, applied in the field of beer brewing, can solve problems such as not being considered beer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

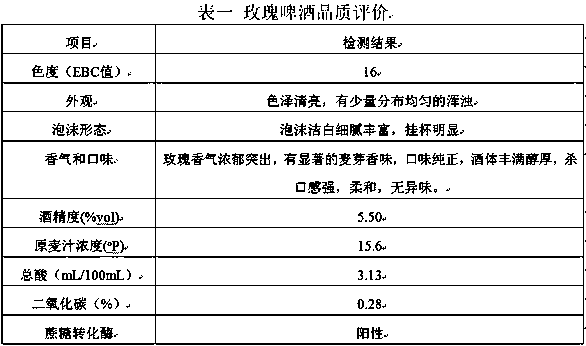

[0089] Specific implementation mode one: Pale rose beer brewing

[0090] This time, a small trial production is carried out on the 200L small beer brewing equipment.

[0091] 1. Brewing raw materials and dosage

[0092] Barley malt: 40kg

[0093] Hops: 200g (alpha-acid content between 3-7%)

[0094] Rose flowers: 2kg.

[0095] 2. Crushed barley malt

[0096] Weigh 40kg of barley malt, add 2L of pure water several times to fully stir to evenly moisten the barley malt skin, and crush the barley malt with a roller mill.

[0097] 3. Barley mashing

[0098] Add 160 liters of clean water into the mash tun, start the agitator, and add the crushed barley malt. The saccharification adopts the boil-out saccharification method, and the specific operation is as follows:

[0099] 1. Add the crushed barley malt into the mash tun, stir and heat up to 37°C, and wet the material for 10 minutes;

[0100] 2. Stir and heat up to 50°C, keep warm for 30 minutes, and stop for protein;

[01...

specific Embodiment approach 2

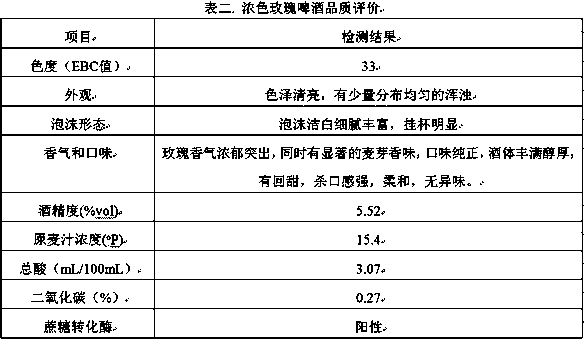

[0120] Specific implementation mode two: brewing of thick rose beer

[0121] Small trial production on 200L small beer brewing equipment

[0122] 1. Brewing raw materials and dosage

[0123] Barley malt: 40kg

[0124] Crystallized malt: 2.5kg (120-150EBC)

[0125] Caramel malt: 2.5kg (120-150EBC)

[0126] Hops: 200g (alpha-acid content between 3-7%)

[0127] Rose flowers: 2kg.

[0128] 2. Crushed barley malt

[0129] Weigh 2.5kg of crystalline malt, 2.5kg of caramel malt and 40kg of barley malt, add 2L of pure water several times and stir thoroughly, and use a roller mill to crush the crystallized malt, caramel malt and barley malt. The wheat germ is broken without breaking, and the malt mixed liquid is obtained.

[0130] 3. Barley mashing

[0131] Add 160 liters of clean water into the mash tun, start the agitator, and add the malt mixed liquid. The saccharification adopts the boil-out saccharification method, and the specific operation is as follows:

[0132] 1. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com