A laser emitting device

A laser emission and laser technology, which is applied in the field of radar, can solve the problems such as the inability of the laser spacing to become very dense, the difficulty of production and adjustment, and the low space utilization rate. volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

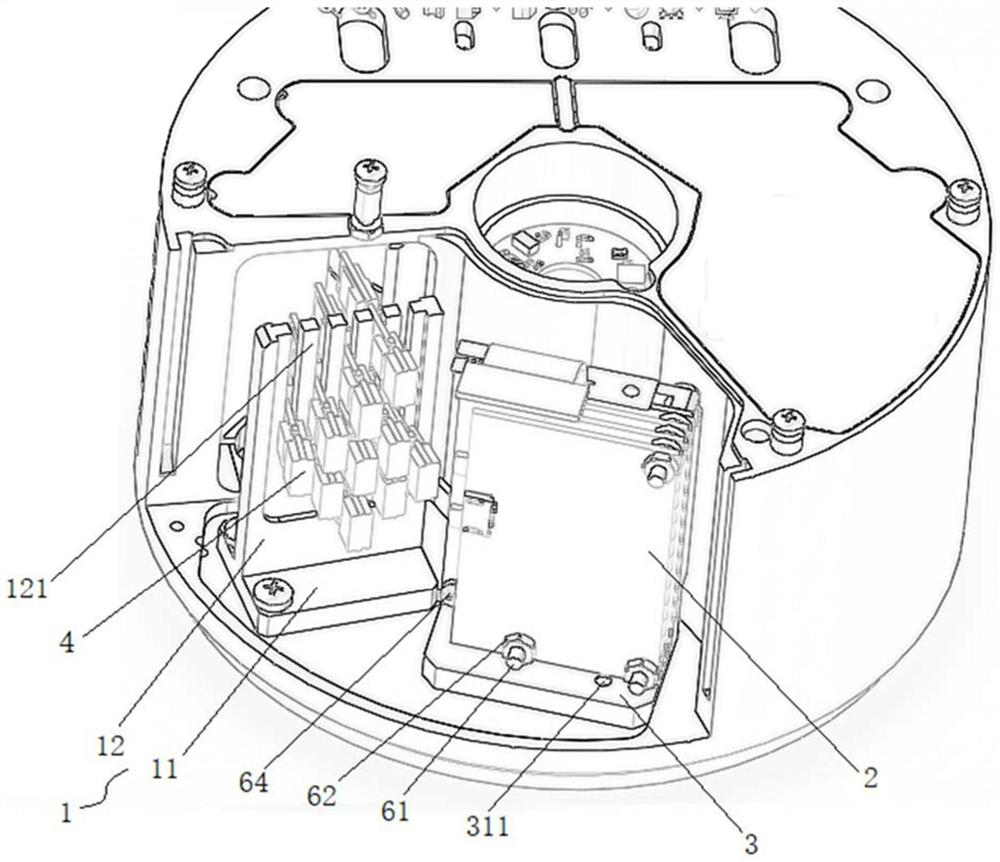

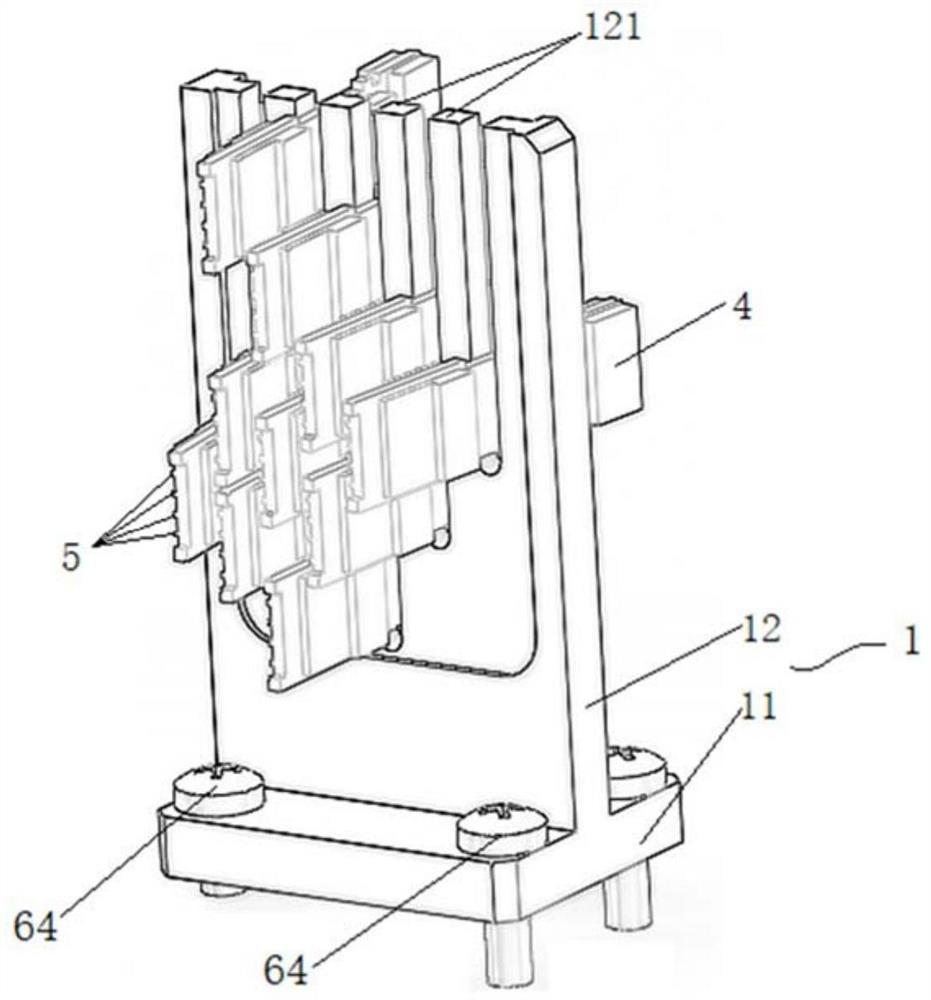

[0067] combine Figure 1 to Figure 5 As shown, a laser emitting device includes a laser bracket 1, a transmitting circuit group 2, a transmitting circuit bracket 3, at least one laser emitting board 4 and a plurality of flexible electrical connectors,

[0068] The laser bracket 1 and the transmitting circuit bracket 3 are arranged at intervals, the laser emitting board 4 is mounted on the laser bracket 1, and at least one laser 5 is arranged on the laser emitting board 4;

[0069] The transmitting circuit group 2 is mounted on the transmitting circuit bracket 3, and the transmitting circuit group 2 is connected to the laser emitting board 4 through the flexible electrical connector.

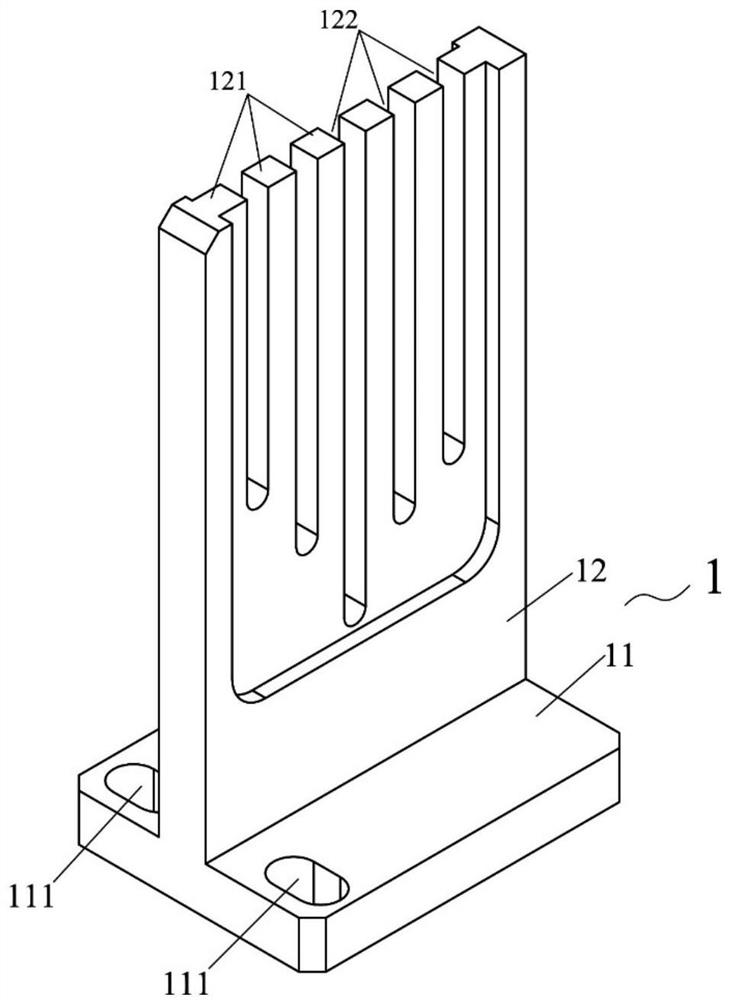

[0070] Such as figure 2 and image 3 As shown, the laser bracket 1 includes a first bottom plate 11 and a first side plate 12, the first bottom plate 11 is connected to the first side plate 12, and the first side plate 12 has a plurality of combs arranged side by side Teeth 121, a slot 122 fo...

Embodiment 2

[0112] refer to figure 1 and figure 2 As shown, a laser emitting device includes a laser bracket 1, a transmitting circuit group 2, a transmitting circuit bracket 3, at least one laser emitting board 4 and a plurality of flexible electrical connectors,

[0113] The laser bracket 1 and the transmitting circuit bracket 3 are arranged at intervals, the laser emitting board 4 is mounted on the laser bracket 1, and at least one laser 5 is arranged on the laser emitting board 4;

[0114] The transmitting circuit group 2 is mounted on the transmitting circuit bracket 3, and the transmitting circuit group 2 is connected to the laser emitting board 4 through the flexible electrical connector.

[0115] Such as Figure 6 As shown, the laser bracket 1 includes a first bottom plate 11 and a first side plate 12, the first bottom plate 11 is connected to the first side plate 12, and the first side plate 12 has a plurality of combs arranged side by side Teeth 121, a slot 122 for installin...

Embodiment 3

[0160] refer to figure 1 and figure 2 As shown, a laser emitting device includes a laser bracket 1, a transmitting circuit group 2, a transmitting circuit bracket 3, at least one laser emitting board 4 and a plurality of flexible electrical connectors,

[0161] The laser bracket 1 and the transmitting circuit bracket 3 are arranged at intervals, the laser emitting board 4 is mounted on the laser bracket 1, and at least one laser 5 is arranged on the laser emitting board 4;

[0162] The transmitting circuit group 2 is mounted on the transmitting circuit bracket 3, and the transmitting circuit group 2 is connected to the laser emitting board 4 through the flexible electrical connector.

[0163] refer to Figure 6As shown, the laser bracket 1 includes a first bottom plate 11 and a first side plate 12, the first bottom plate 11 is connected to the first side plate 12, and the first side plate 12 has a plurality of combs arranged side by side Teeth 121, a slot 122 for installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com