Component-based CMDB propellant mechanical prediction method

A technology of propellant and mechanics, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of model parameter acquisition relying on experimental data, gap between model prediction and actual demand, and insufficient systematic and in-depth research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In order to verify the feasibility of the method, the mass fractions of the selected CMDB propellant components are: 50% nitrocellulose NC (12.5% nitrogen content), 32% NG, 10% Octogen HMX, and the remaining additives 8%.

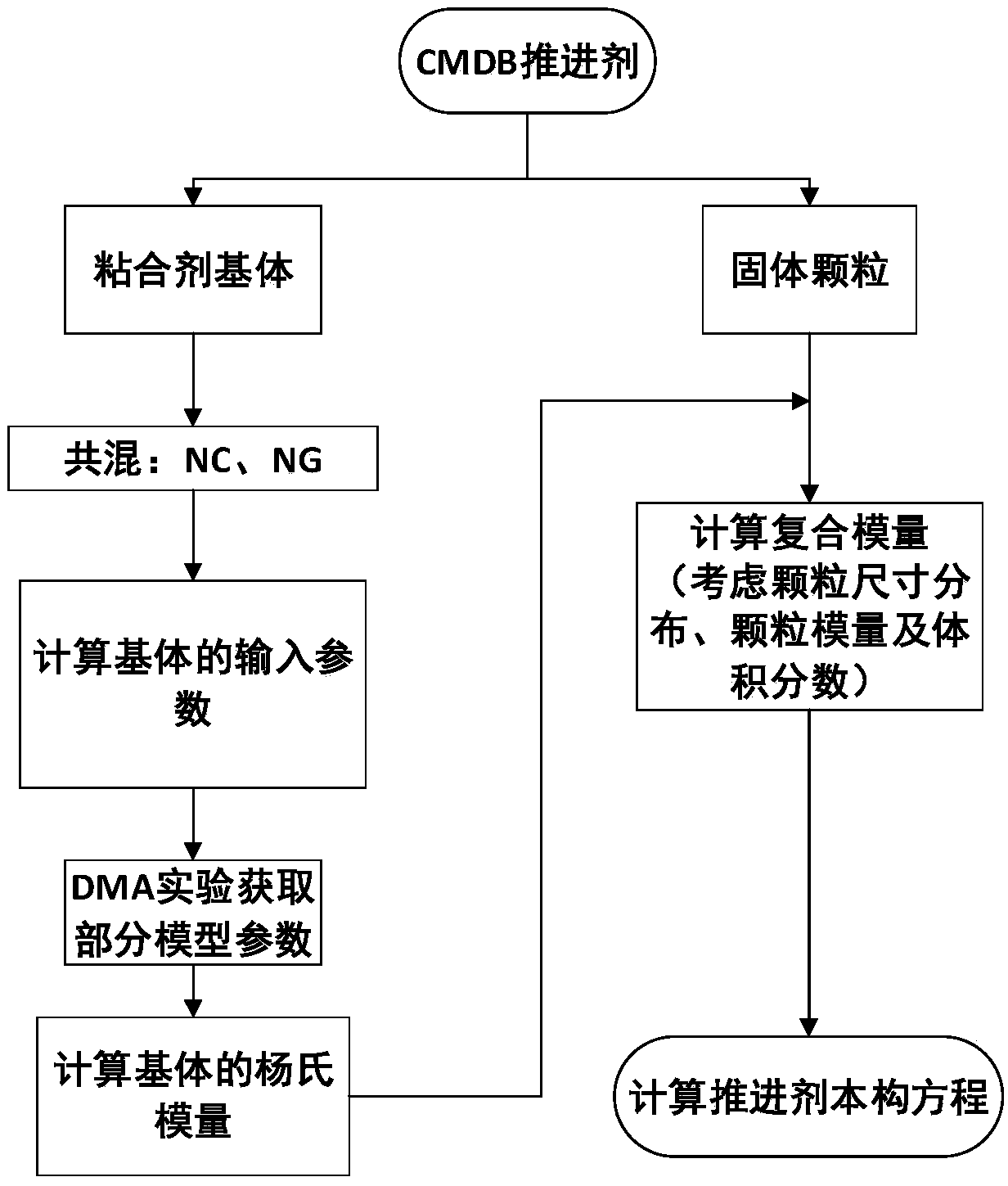

[0083] like figure 1 As shown, a component-based CMDB propellant mechanics prediction method disclosed in this embodiment includes the following steps:

[0084] Step 1: Select and obtain the input parameters of the components according to the atomic group contribution and selection principle table.

[0085] Obtain the molecular degree of freedom N and zero-point binding energy E of the chemical bond by looking up the contribution of the atomic group and the selection principle table coh , and the van der Waals volume V w . According to the principle of superposition, the molecular degree of freedom N=61.3 and the zero-point binding energy E of nitrocellulose NC in CMDB propellant can be respectively determined coh =235070J / mol, and van der Waals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com