High-power-density high-efficiency high-reliability magnetic claw motor

A high-power-density, high-efficiency technology, applied to synchronous motors with rotating armatures and stationary magnets, etc., can solve problems such as increased inverter capacity, complex claw pole structure, and low power factor, and achieve improved torque ability, improved mechanical strength, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

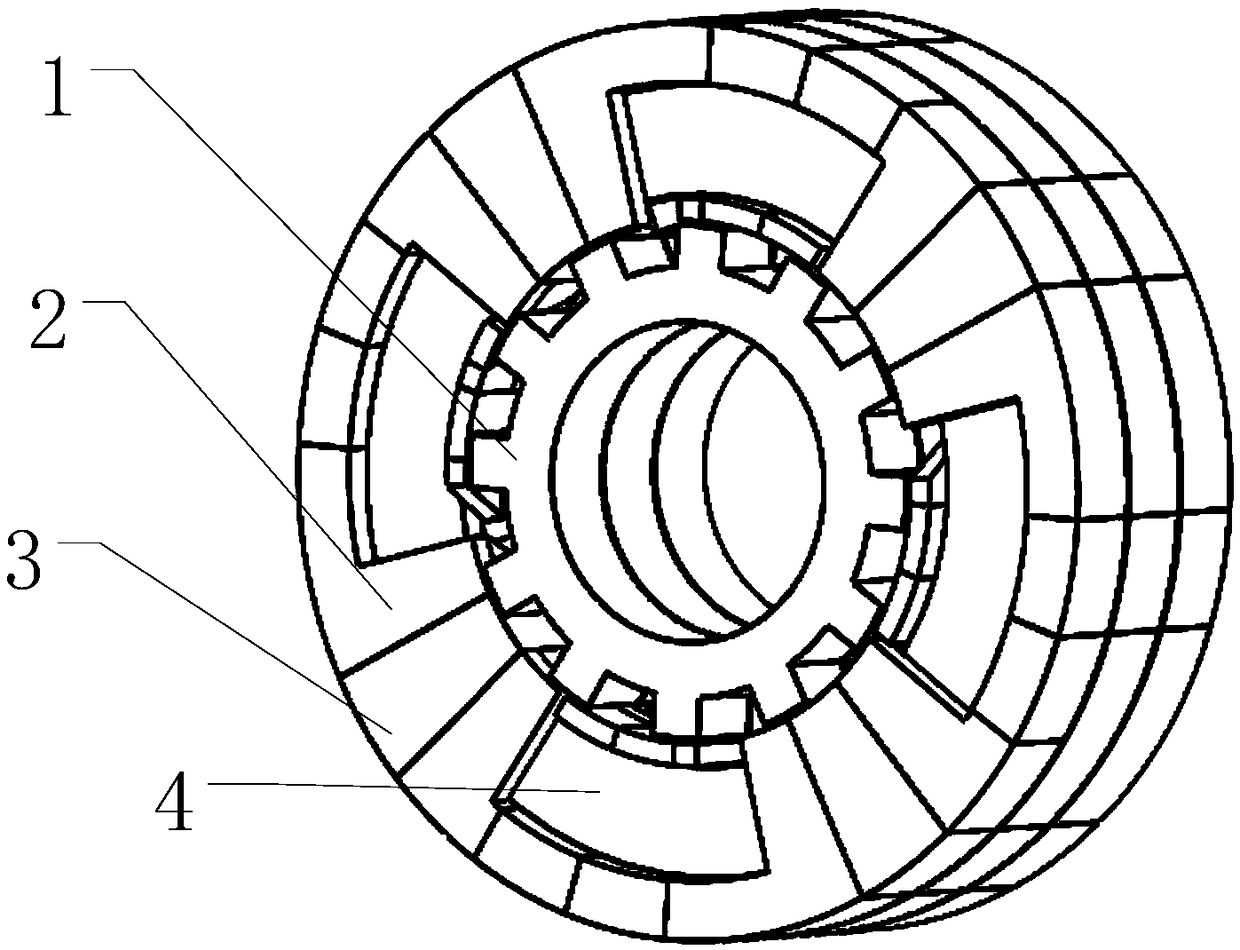

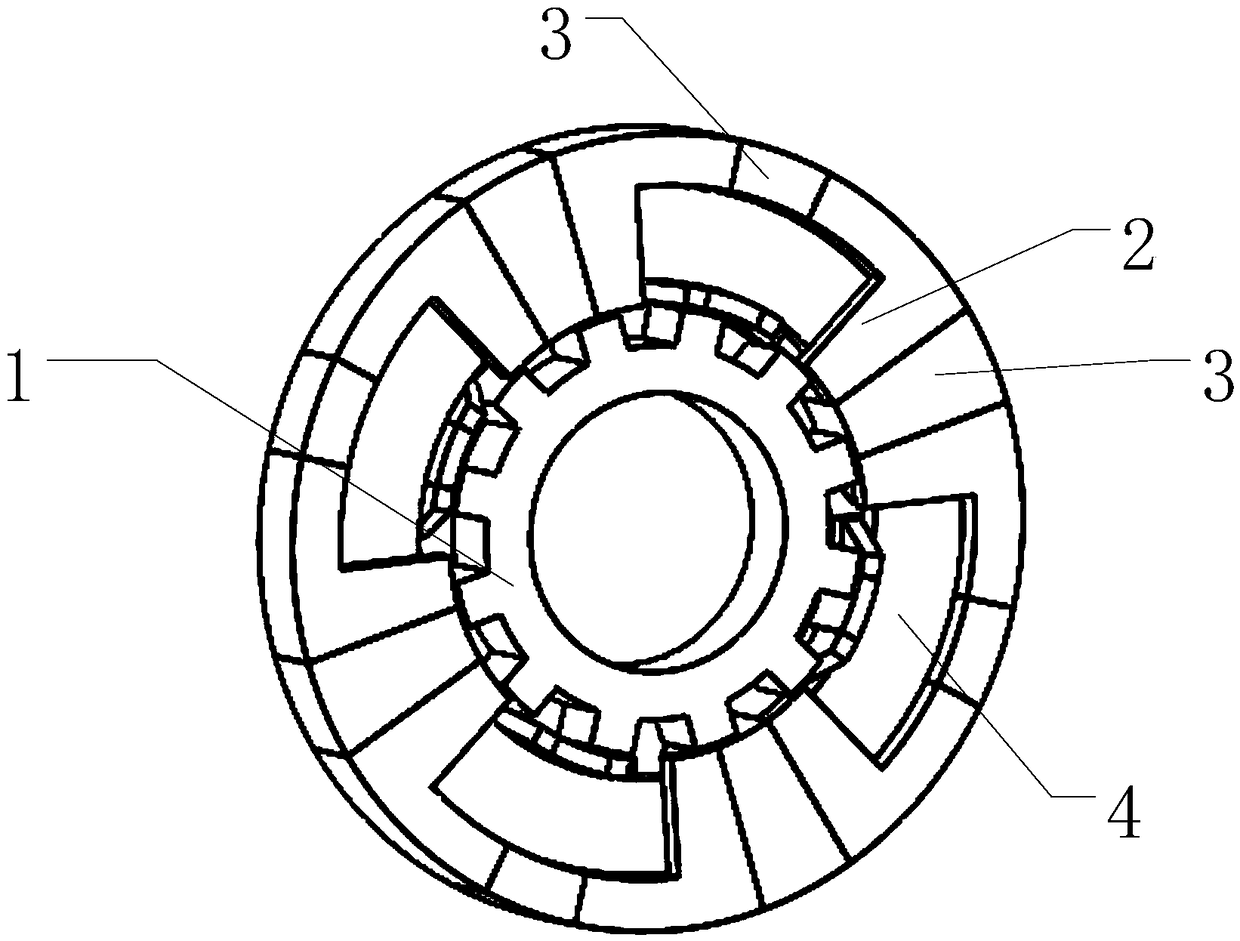

[0045] The magnetic claw motor with high power density, high efficiency and high reliability of this embodiment is composed of a plurality of magnetic claw motor modules, and two adjacent magnetic claw motor modules are axially offset by a specific angle on the stator side. They are all single-stator and single-rotor structures, including a rotor magnetic core 1 , a stator magnetic core 2 , an embedded special-shaped permanent magnet 3 , and an armature winding 4 .

[0046] The rotor is only composed of a rotor magnetic core 1; the rotor magnetic core 1 is a salient pole cogging structure, which is formed by laminating silicon steel sheets;

[0047] The stator magnetic core 2 is of unequal width claw pole structure, adopts the manufacturing process of molding, and the material used is SMC;

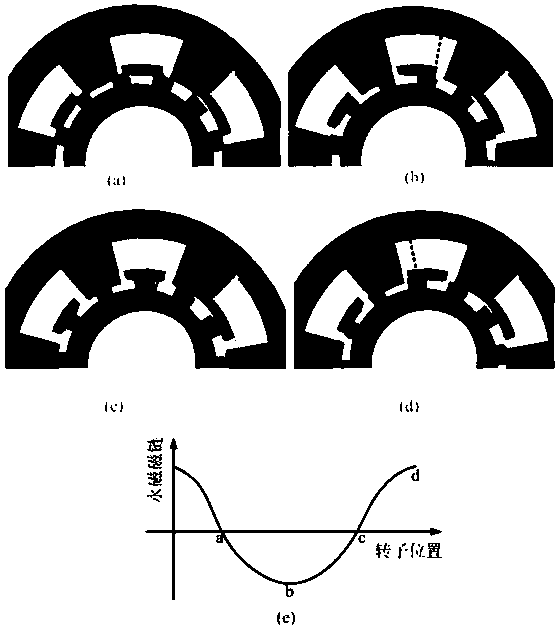

[0048] The special-shaped permanent magnets 3 are made of ferrite materials, and are magnetized along the circumferential direction of the magnetic claw motor, and the magnetization direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com