Visual guidance method applicable to automobile door automatic assembling process

An automatic loading, vision-guided technology, applied in motor vehicles, transportation and packaging, program-controlled manipulators, etc., can solve the problems of large random errors in the assembly process, inaccurate assembly positions, poor sealing in the car, etc., to achieve precision. , The effect of reducing door assembly errors and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

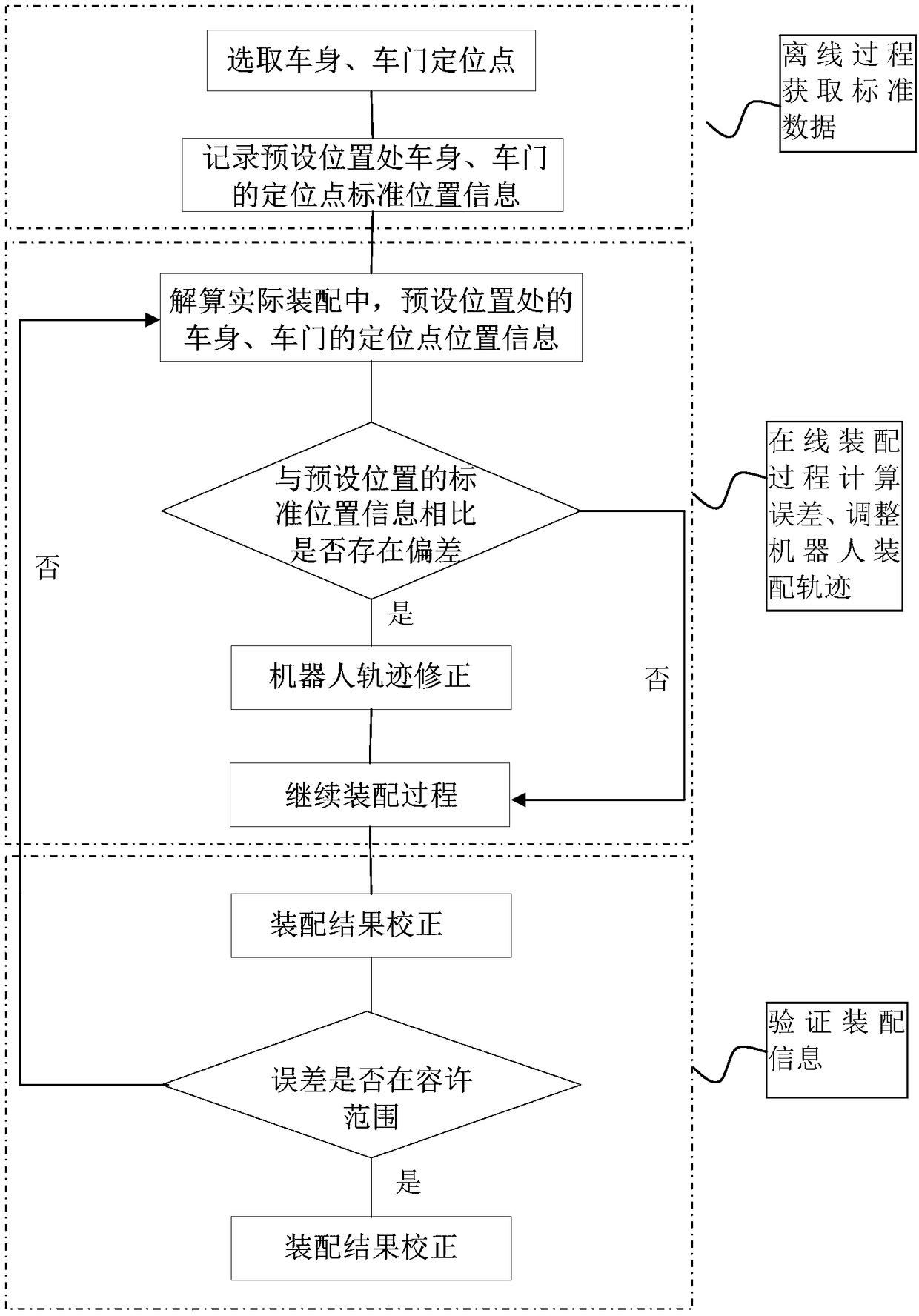

[0047] A visual guidance method applicable to the automatic loading process of automobile doors, comprising the following steps:

[0048] 1. Obtain standard data in offline process

[0049] The standard data stored in the system is obtained according to the following steps:

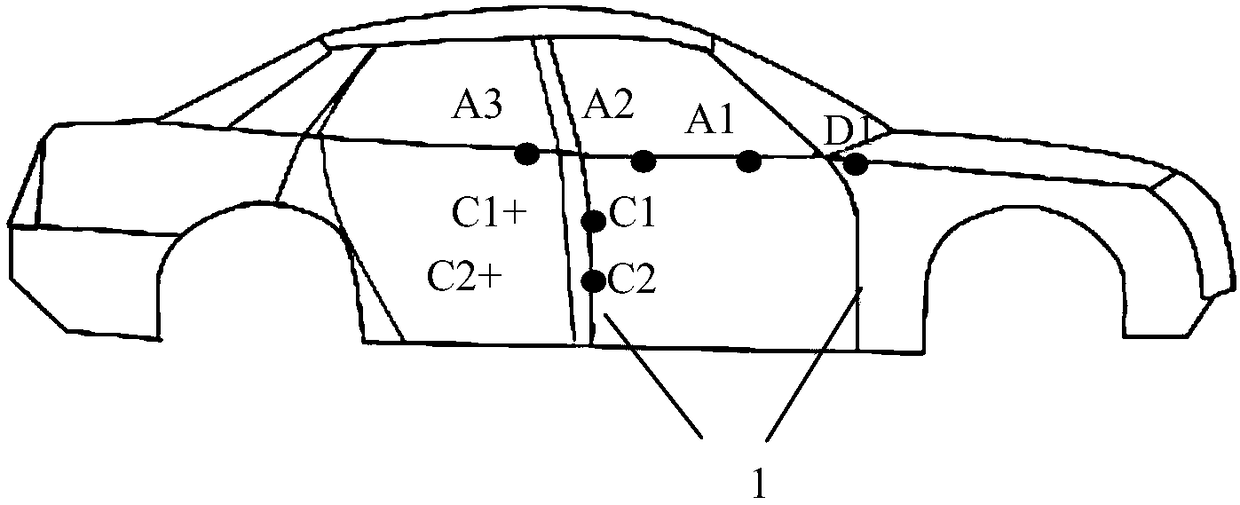

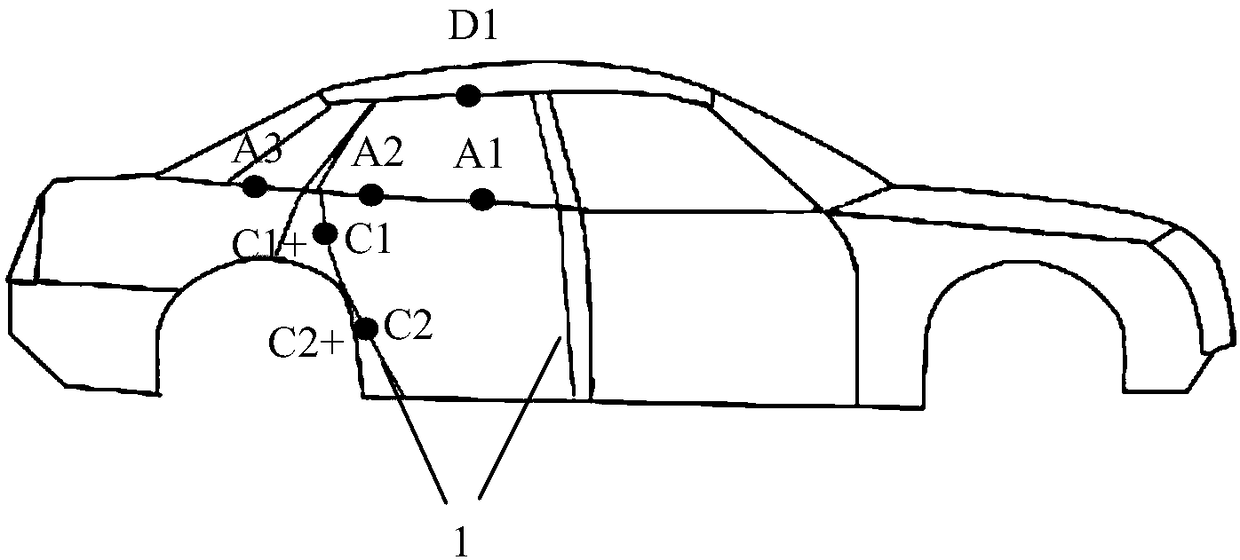

[0050] ① After adjustment, when the robot can accurately complete the door assembly and the gap between the door and the car body is within the preset range, record the multiple points distributed along the car body from front to back as the positioning point A, and connect the positioning points A to form a straight line; figure 2 or image 3 As shown, there are three positioning points A in this embodiment, which are respectively marked as A1, A2, and A3, and wherein two points (A1, A2) are distributed on the same car door;

[0051] Note that the gap line between the longitudinal edge of the door opening and closing position and the car body is the first reference line 1; corresponding to the same p...

Embodiment 2

[0064] A visual guidance method applicable to the automatic loading process of automobile doors, comprising the following steps:

[0065] 1. Obtain standard data in offline process

[0066] ①The standard data stored in the system is obtained according to the following steps:

[0067] After adjustment, when the robot can accurately complete the door assembly, and the gap between the door and the car body is within the preset range, record the multiple points distributed along the car body from front to back as the positioning point A, and connect the positioning points A to form a Continuous curve, the continuous curve formed by connecting the anchor point A coincides with the extension line of the car waistline; for example figure 2 or image 3 As shown, there are three positioning points A in the present embodiment, which are respectively marked as A1, A2, and A3, wherein two points (A1, A2) are distributed on the same car door;

[0068] Note that the gap line between the...

Embodiment 3

[0092] A visual guidance method suitable for the automatic loading process of automobile doors. The difference between this embodiment and the above-mentioned embodiment 2 lies in: the selection of the positioning points of the vehicle body and the vehicle door in the offline process and the online assembly process. Specifically, record along The multiple points distributed from the front to the rear of the vehicle body are the positioning points A, connecting the positioning points A can form a continuous curve, and a straight line formed by connecting the positioning points A coincides with the extension line of the lower edge of the window; as shown in Figure 9 or Figure 10 As shown, there are four positioning points A in this embodiment, respectively marked as A1, A2, A3, A4, wherein two points (A1, A2) are distributed on the same door;

[0093] Note that the gap line between the longitudinal edge of the door opening and closing and the vehicle body is the first reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com