Portable suspension conveying system and suspension conveyor for spraying

A conveying system and a convenient technology, which is applied in the direction of conveyors, spraying devices, transportation and packaging, etc., can solve the problems of large site space, large energy consumption, complex layout, etc., to overcome the occupation of production sites, reduce energy consumption, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

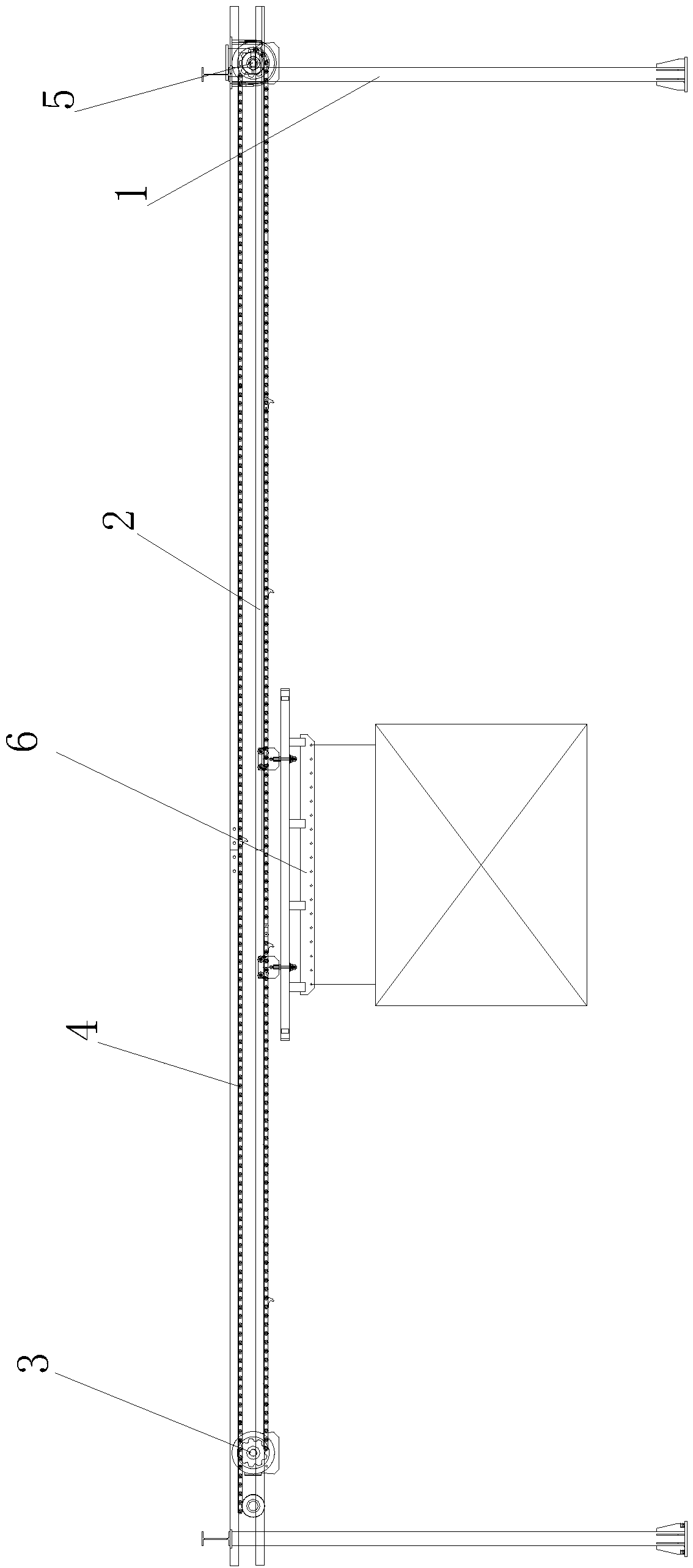

[0057] This embodiment includes a portable suspension conveying system, including a track system, a stacking car group and a control system;

[0058] The track system includes a linear conveying section supported by a steel structure frame 1, a traverse device, a turnout device and a turning device; the steel structure frame 1 is a general-purpose steel structure connected by assembly or welding. The steel structure frame is mainly used to hang and carry the weight of the conveyor line body and products, so that the entire conveyor system is in a suspended state.

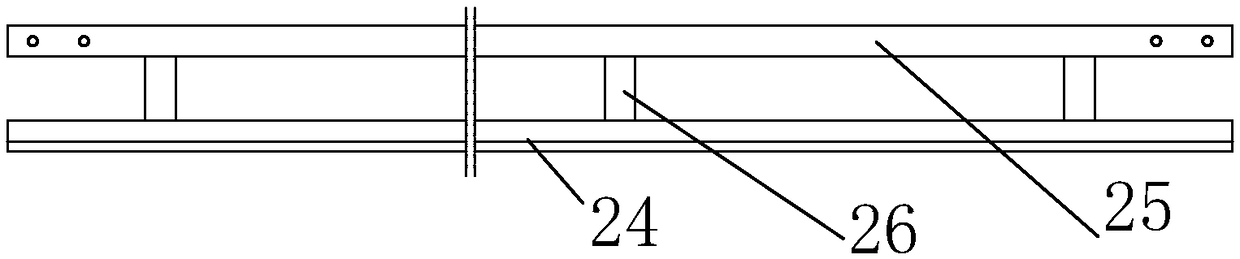

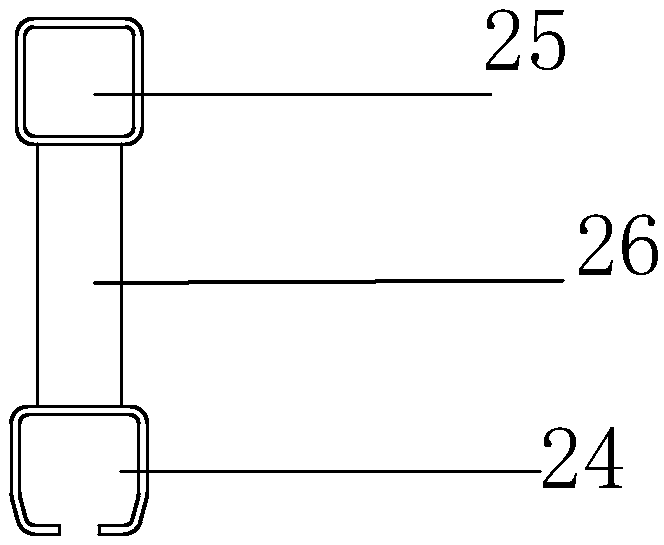

[0059] The linear conveying section comprises a straight rail 2 and a traction drive, and the straight rail includes a reinforcing beam 26 and a C-shaped track 24 arranged in parallel, and a connecting beam 25 is vertically arranged between the reinforcing beam 26 and the C-shaped track 24; The opening of the C-shaped track 24 is downward. The traction transmission device includes a driving device 3, a traction rop...

Embodiment 2

[0068] This embodiment builds a kind of suspension conveyor for the paint spraying industry based on embodiment 1, such as Figure 15 As shown, according to the running sequence of the conveyor, it includes the first linear conveying section 101, the first traversing device 102, the second linear conveying section 103, the second traversing device 104, the third linear conveying section 105, the switch device 106, The fourth linear conveying section 107, the first rotary device 108, the accumulation and storage device 109 and the second rotary device 110;

[0069] The first straight line conveying section is provided with the unloading area 001 and the loading area 002, the end of the loading area 002 is connected with the first traverse device 102, and the products are transported to the upper line area 002, and are transported to the production line with the assistance of manual or workshop cranes The accumulative car group is hung up, and after the hoisting is completed, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com