A kind of seamless bridge expansion joint based on phosphorus and magnesium material and its construction method

A technology of seamless bridges and expansion joints, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of low service life, complicated construction, low early strength, etc., achieve increased bulk density and compressive strength, and easy construction and operation , the effect of high early intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

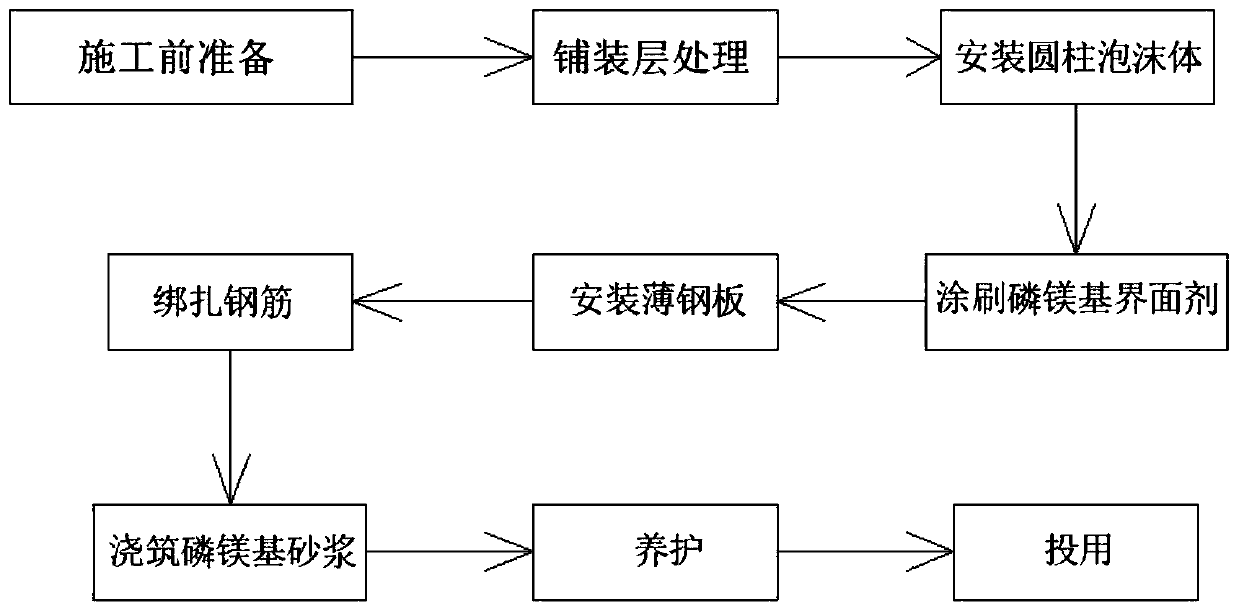

Method used

Image

Examples

Embodiment 1

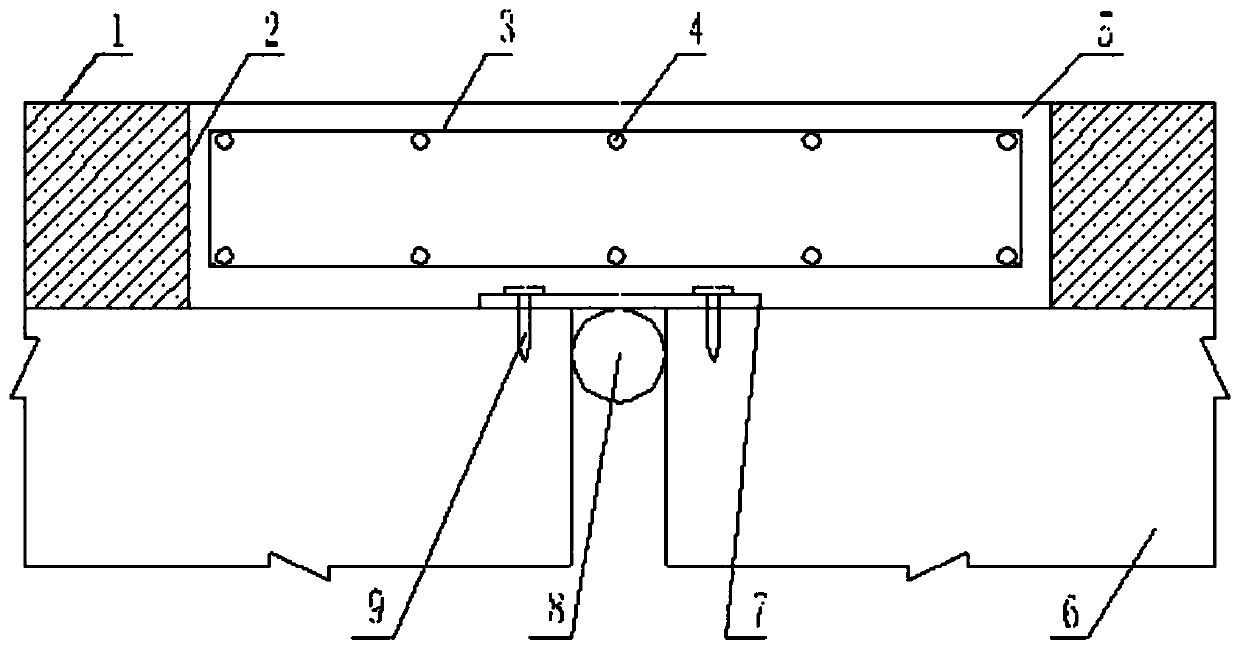

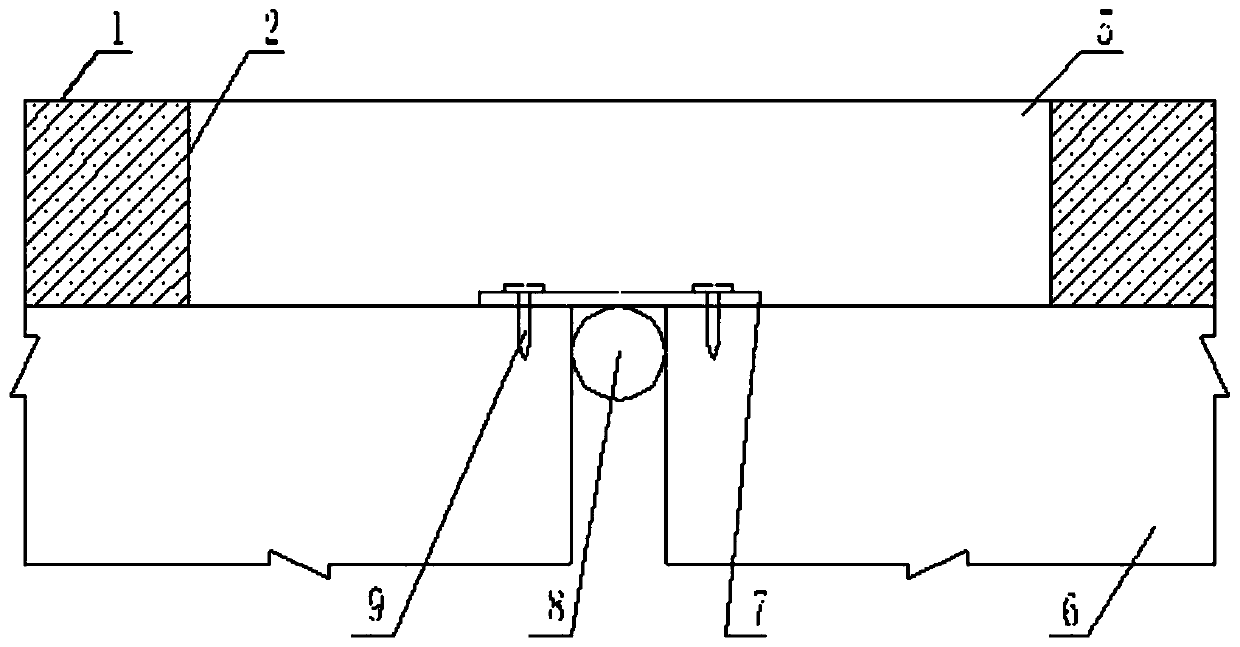

[0061] like figure 1 Shown, a kind of seamless bridge expansion joint based on phosphorus magnesium material, comprises pavement layer 1 and cast-in-place concrete layer 6, is provided with phosphorus-magnesium material interface layer between said pavement layer 1 and cast-in-place concrete layer 6 2. The thin steel plate 7 and the transverse steel bar 3 and the vertical steel bar 4 arranged on the inner side of the interface layer 2 of phosphorus-magnesium material. The thin steel plate 7 is arranged on the crack of the cast-in-place concrete layer 6. 1. The interface layer 2 of phosphorus and magnesium material, the gap between the cast-in-place concrete layer 6 and the thin steel plate 7 is filled with a phosphorus and magnesium mortar layer 5 .

[0062] Further, the horizontal steel bar 3 is rectangular, the vertical steel bar 4 is arranged inside the horizontal steel bar 3, and the vertical steel bar 4 is connected with the horizontal steel bar 3 through a steel wire; th...

Embodiment 2

[0077] like figure 1 Shown, a kind of seamless bridge expansion joint based on phosphorus magnesium material, comprises pavement layer 1 and cast-in-place concrete layer 6, is provided with phosphorus-magnesium material interface layer between said pavement layer 1 and cast-in-place concrete layer 6 2. The thin steel plate 7 and the transverse steel bar 3 and the vertical steel bar 4 arranged inside the interface layer 2 of the phosphorus-magnesium material, the thin steel plate 7 is arranged on the crack of the cast-in-place concrete layer 6, the horizontal steel bar 3 and the paving 1. The interface layer 2 of phosphorus and magnesium material, the gap between the cast-in-place concrete layer 6 and the thin steel plate 7 is filled with a phosphorus and magnesium mortar layer 5 .

[0078]Further, the horizontal steel bar 3 is rectangular, the vertical steel bar 4 is arranged inside the horizontal steel bar 3, and the vertical steel bar 4 is connected with the horizontal steel...

Embodiment 3

[0093] like figure 1 Shown, a kind of seamless bridge expansion joint based on phosphorus magnesium material, comprises pavement layer 1 and cast-in-place concrete layer 6, is provided with phosphorus-magnesium material interface layer between said pavement layer 1 and cast-in-place concrete layer 6 2. The thin steel plate 7 and the transverse steel bar 3 and the vertical steel bar 4 arranged on the inner side of the interface layer 2 of phosphorus-magnesium material. The thin steel plate 7 is arranged on the crack of the cast-in-place concrete layer 6. 1. The interface layer 2 of phosphorus and magnesium material, the gap between the cast-in-place concrete layer 6 and the thin steel plate 7 is filled with a phosphorus and magnesium mortar layer 5 .

[0094] Further, the horizontal steel bar 3 is rectangular, the vertical steel bar 4 is arranged inside the horizontal steel bar 3, and the vertical steel bar 4 is connected with the horizontal steel bar 3 through a steel wire; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com