Intelligent coal-mine gas extraction pump station and working method thereof

A technology for coal mine gas and pumping stations, which is applied in the field of intelligent coal mine gas drainage and pumping stations, can solve problems such as downtime, unreliable system, lack of redundant design, etc., and achieve the effect of system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

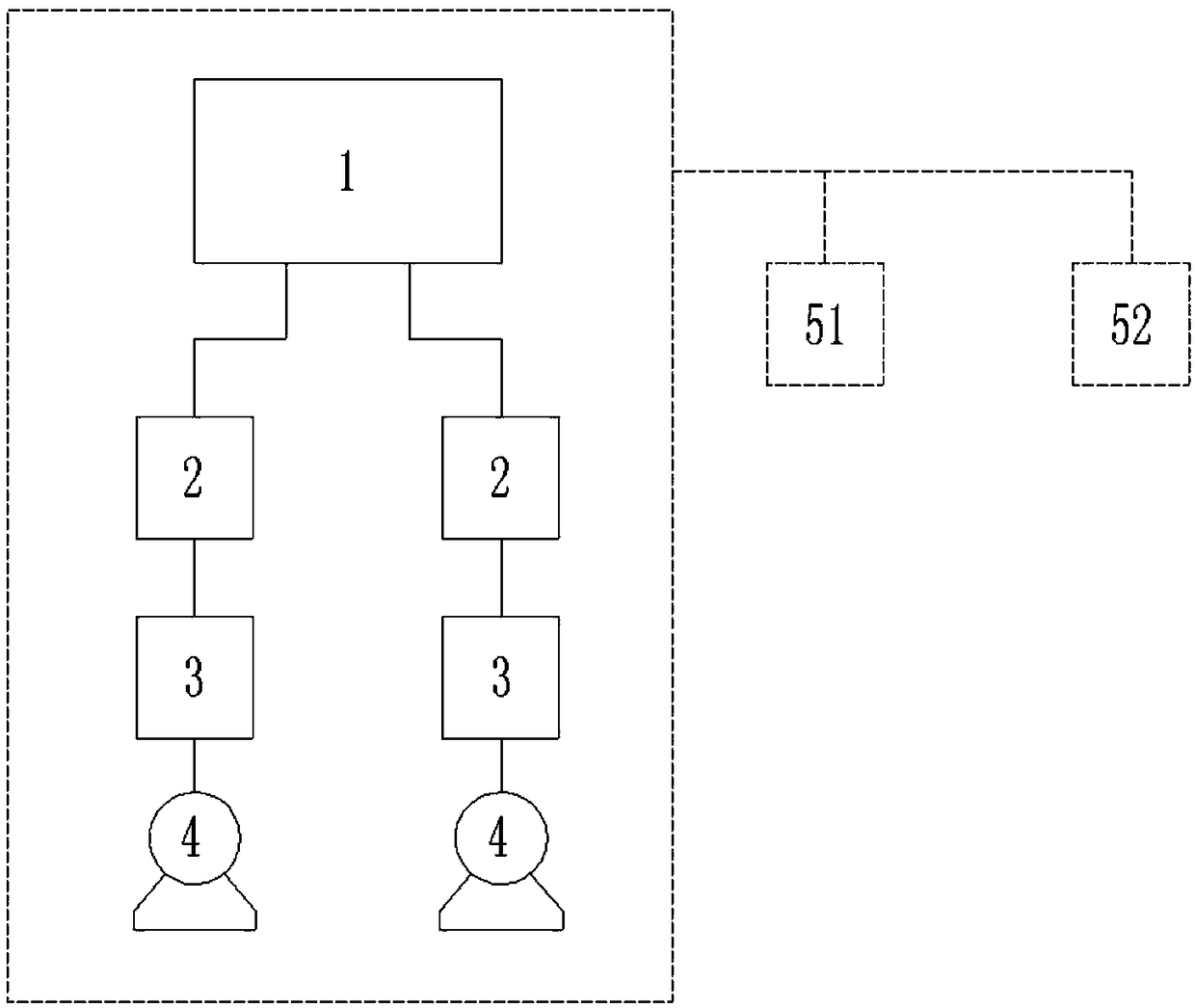

[0034] An intelligent water ring vacuum pump for coal mine gas extraction, including a control device 1, the control device 1 is connected to control several frequency converters 2, and each frequency converter 2 is connected to control a water ring vacuum pump 4, each A contactor 3 is installed between each water ring vacuum pump 4 and the frequency converter 2 , and the control circuit of the contactor 3 is electrically connected with the control device 1 .

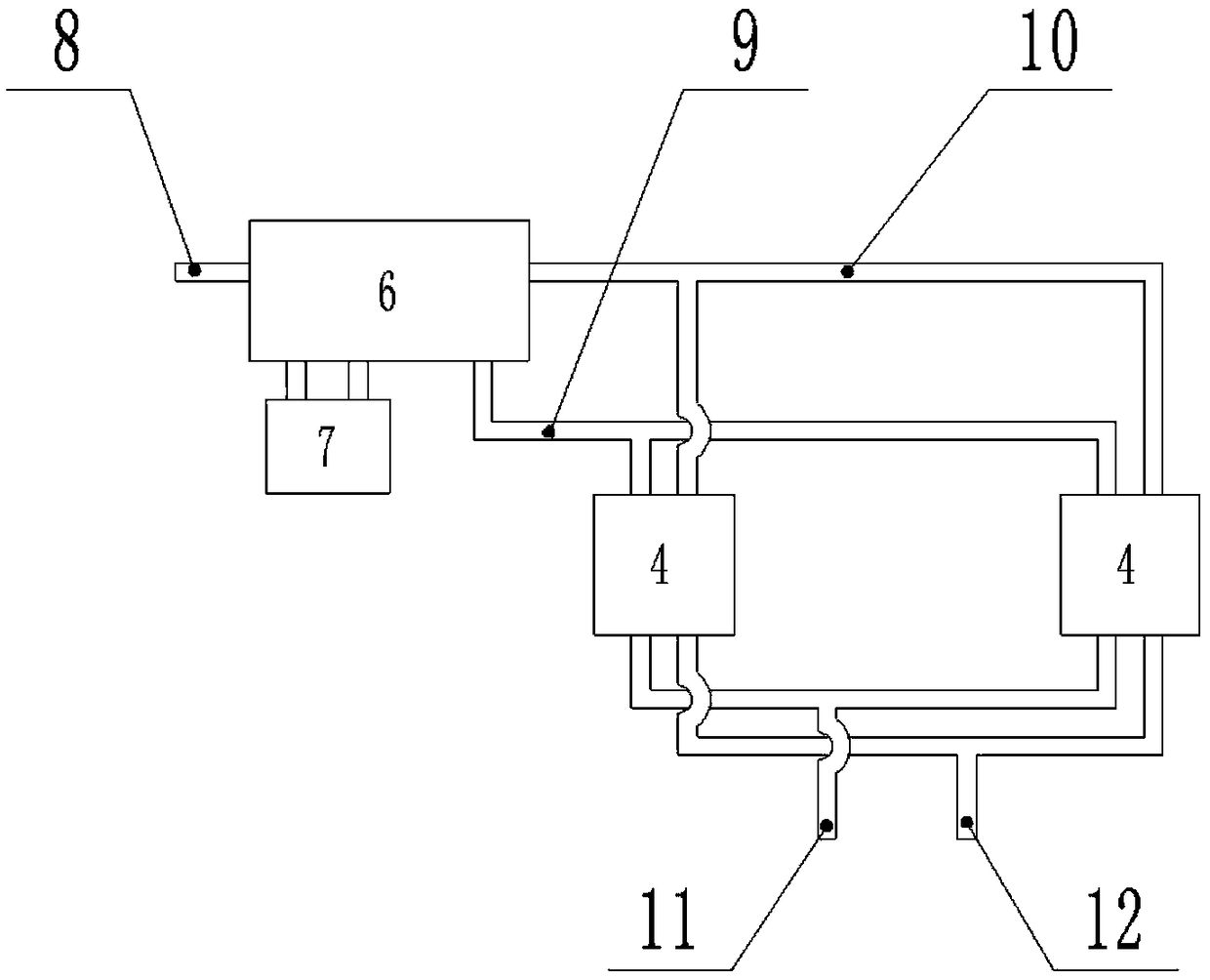

[0035] It also includes a water tank 6, a water inlet pipeline 9, a drain pipeline 10, an exhaust pipeline 11 and an air extraction pipeline 12. The water tank 6 is equipped with a replenishment pipe 8, and the water replenishment pipe 8 is used to supplement the water in the water tank 6. Water, the circulating water inlet of the water ring vacuum pump 4 communicates with the water tank 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com