Method for distinguishing quality of frying oil through combination of gas chromatographic fingerprint and principal component analysis method

A principal component analysis and fingerprint technology, applied in the field of oil identification, can solve the problems of inability to comprehensively reflect the chemical characteristics and structural characteristics of oil, poor repeatability, large amount of consumables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

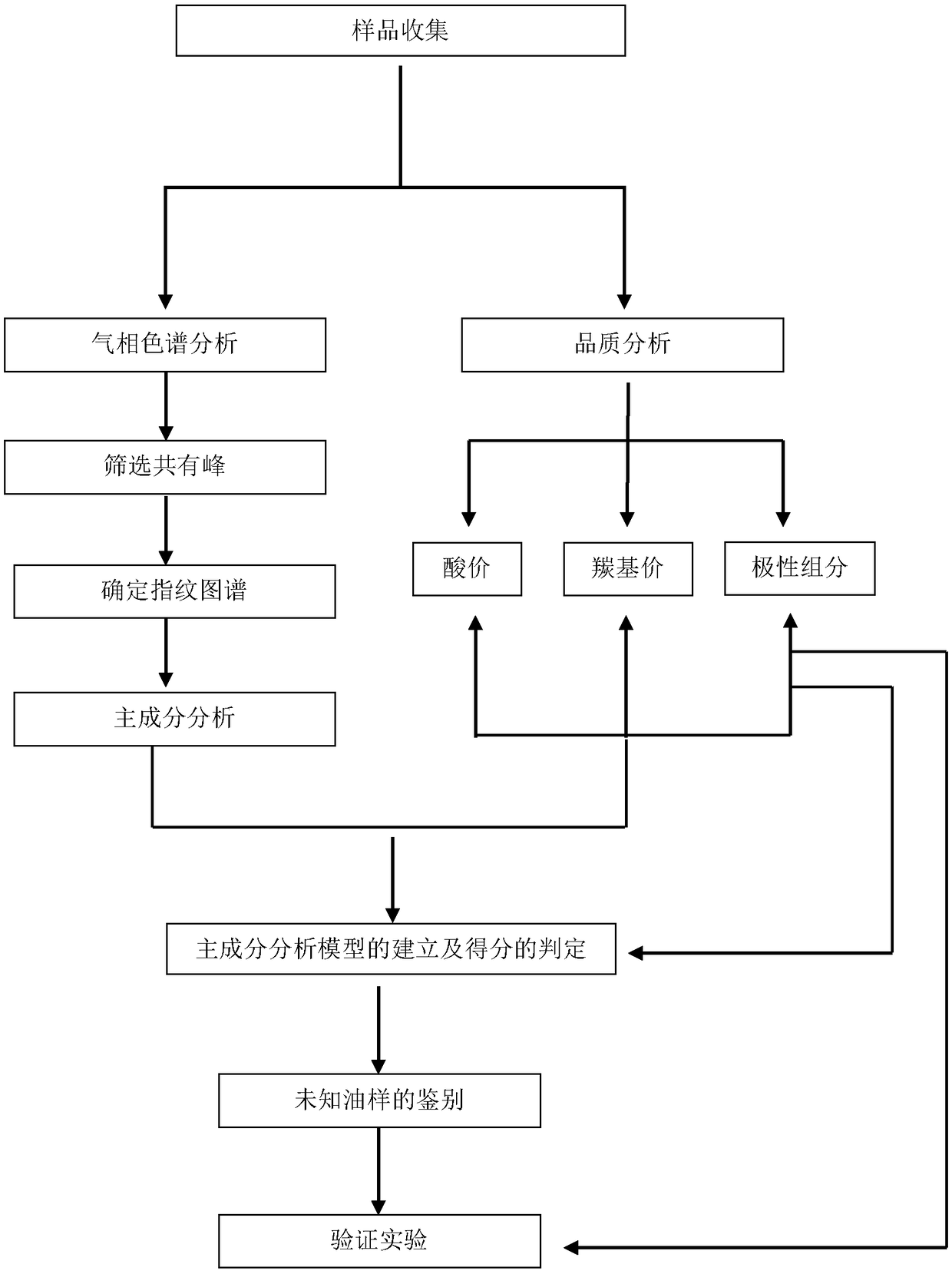

Method used

Image

Examples

Embodiment 1

[0052] (1) The establishment of the gas phase fingerprint database of frying oil standard samples

[0053] (1) Select a sample of soybean oil that has been continuously fried for 30 hours and perform gas chromatographic analysis for 3 to 5 times in parallel to obtain gas chromatographic data with a retention time of 20 to 70 min, including the retention time of each gas chromatographic peak and the corresponding Peak area;

[0054] (2) According to the chromatographic peak retention time and peak type of each sample, screen the common peaks of the samples;

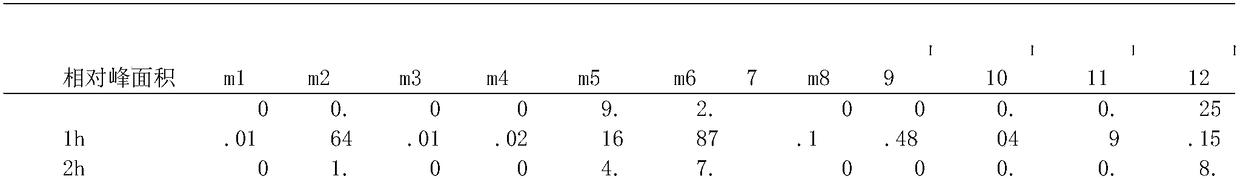

[0055] (3) Select the peak with suitable retention time and peak area as the reference peak, and calculate the relative peak area Ar (Ar=Ai / As) of the shared peak, see Table 1;

[0056] Table 112 The relative peak area of the common peaks (select the No. 7 peak with better peak shape and retention time as reference peak)

[0057] Table 1 Relative peak area values of all samples

[0058]

[0059]

[0060] (2) Comprehensive evalua...

Embodiment 2

[0079] Take 5 samples of frying oil from the Zaodian store near Beijing Technology and Business University for 5 consecutive days, denote them as Day1, Day2, Day3, Day4, Day5 respectively, and perform the methyl esterification of the samples, and then import the gas phase data after gas chromatography analysis. In the similarity evaluation software of traditional Chinese medicine chromatographic fingerprints, by comparing with the common peaks of standard samples, the breakfast shop uses soybean oil. According to the peak shape and peak area, the sampling on the third day is better, and the third day is selected. The frying oil sample Day3 is the reference peak, and the relative peak area of each frying oil sample is calculated separately for principal component analysis;

[0080] It can be seen from Table 6 that the comprehensive score of Day1 is -2.53<-2.442948753<-2.39, which is old frying oil; the comprehensive score of Day2 is -6.921513579<-2.53, which is good frying oil; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com