Monitoring deviation timely reminding technology of reverse osmosis nanofiltration system

A technology of system monitoring and reverse osmosis, applied in reverse osmosis, membrane technology, osmosis/dialysis water/sewage treatment, etc., can solve problems such as system misjudgment and error, and achieve the effect of reducing operation maintenance and personnel management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For setting forth the present invention in more detail, the present invention is implemented as follows:

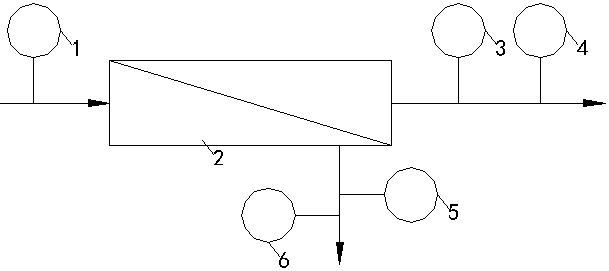

[0014] As shown in the accompanying drawings, a reverse osmosis nanofiltration system monitoring deviation timely prompting technology described in the example of the present invention includes an influent water conductivity meter (1), a reverse osmosis nanofiltration system (2), and a produced water conductivity meter (3 ), influent flow meter (4), concentrated water conductivity meter (5), concentrated water flow meter (6). The inlet water conductivity meter (1) is installed on the water inlet pipeline of the system, the water inlet of the reverse osmosis nanofiltration system (2) is connected to the inlet water conductivity meter (1) through the pipeline, and the product water conductivity The instrument (3) and water inlet flow meter (4) are installed on the water production pipeline of the system, and are connected to the water production port of the reverse o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com