Preparation method of high-activity palladium carbon hydroxide based on microreactor

A technology of palladium hydroxide carbon and micro-reactor, which is applied in the field of preparation of highly active palladium hydroxide carbon, can solve the problems of uneven mixing, uneven heating, weakening of catalyst activity, etc., and achieve uniform catalyst particles, high catalytic activity, The effect of solving mass and heat transfer problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

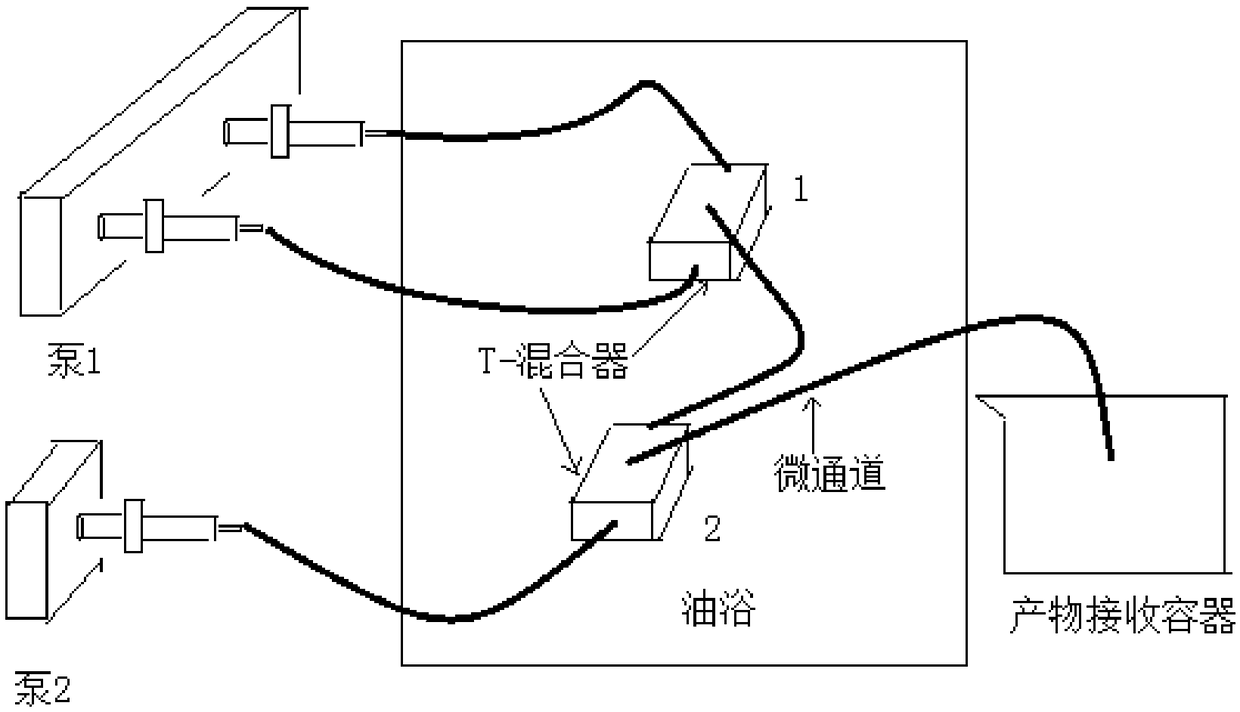

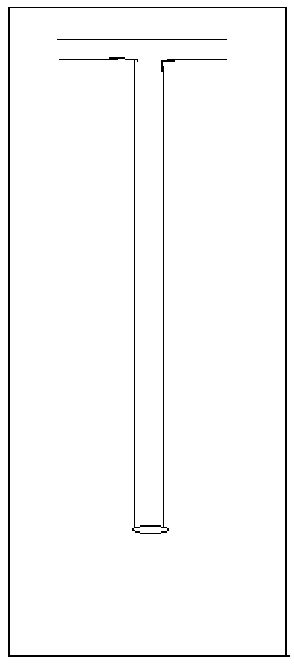

[0027] A kind of preparation method based on the high activity palladium hydroxide carbon of microreactor, adopts microreactor, comprises the following steps:

[0028] (1) 5.0g of carbon black particles were pulverized to obtain carbon black powder, and 500mL of deionized water was added, which was then ultrasonically dispersed to obtain a carbon black slurry;

[0029] (2) dissolving the precipitant sodium carbonate in water to obtain a precipitant solution; ultrasonically dissolving the palladium salt in water to obtain a palladium salt solution;

[0030] (3) Use one of the syringe pump, plunger pump, diaphragm pump and peristaltic pump to inject the carbon black slurry and the precipitant solution into the microreactor at 2.5mL / min, and use a constant temperature oil bath to control The temperature is in the range of 50-100°C;

[0031] (4) Using one of a syringe pump, a plunger pump, a diaphragm pump and a peristaltic pump, inject the palladium salt solution into the micror...

Embodiment 2

[0035] A kind of preparation method based on the high activity palladium hydroxide carbon of microreactor, adopts microreactor, comprises the following steps:

[0036] (1) 5.5g of carbon black particles were pulverized to obtain carbon black powder, and 1000mL of deionized water was added, and then ultrasonically dispersed to obtain carbon black slurry;

[0037] (2) dissolving the precipitating agent sodium hydroxide in water to obtain an intermediate solution; ultrasonically dissolving the palladium salt in water to obtain a palladium salt solution;

[0038] (3) Utilize a kind of in syringe pump, plunger pump, diaphragm pump and peristaltic pump, inject carbon black slurry and palladium salt solution in the microreactor with 20mL / min respectively, utilize constant temperature oil bath to control temperature at 100°C;

[0039] (4) Using one of the syringe pump, plunger pump, diaphragm pump and peristaltic pump, inject the precipitant into the microreactor at 40mL / min, and use...

Embodiment 3

[0043] A kind of preparation method based on the high activity palladium hydroxide carbon of microreactor, adopts microreactor, comprises the following steps:

[0044] (1) 5.2g of carbon black particles were pulverized to obtain carbon black powder, and 800mL of deionized water was added, which was then ultrasonically dispersed to obtain a carbon black slurry;

[0045] (2) dissolving the precipitant sodium hydroxide in water to obtain an intermediate solution; ultrasonically dissolving the palladium salt in water to obtain a palladium salt solution;

[0046] (3) Using one of the syringe pump, plunger pump, diaphragm pump and peristaltic pump, inject the carbon black slurry and the precipitant solution or the carbon black slurry and the palladium salt solution into the microreactor at 10mL / min respectively In the process, use a constant temperature oil bath to control the temperature within the range of 80°C;

[0047] (4) Using one of the syringe pump, plunger pump, diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com