Classification system for building residue soil

A classification system and construction dregs technology, applied in construction waste recycling, solid separation, recycling technology, etc., can solve the problems of large amount of manual processing, large site occupation area, low degree of automation, etc., and achieve significant economic benefits and social benefits, small footprint and site area, and high degree of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

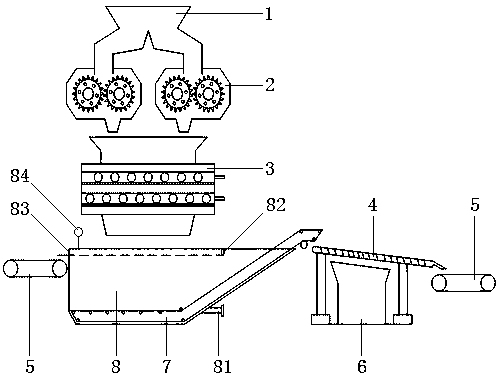

[0020] refer to figure 1 , a kind of construction dregs classification system of the present invention, it comprises crusher 2, iron remover 3, water tank 8 and vibration screening device 4 connected in sequence, the input end of described crusher 2 is also provided with feed hopper 1, The top of described vibratory screening device 4 is inclined to be equipped with sand filter screen, and the below of described sand filter screen is provided with sand collection box 6, and the bottom end of sand filter screen in vibratory screening device 4 is connected with belt conveyor 5; One side of the water tank 8 is provided with an overflow tank 83 and a liquid level valve 84 , and a sprocket conveyor 7 is also provided in the water tank 8 to connect with the input end of the vibration screening device 4 .

[0021] Such as figure 1 As shown, three of the sides of the water tank 8 in the present invention are arranged at right angles to the bottom plate, and the other side is inclined...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap