Double-working-station modularization grinding and polishing robot

A modular and robotic technology, applied in grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problems of cumbersome work, single working mode, long part positioning time, etc., to reduce processing procedures, improve processing efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

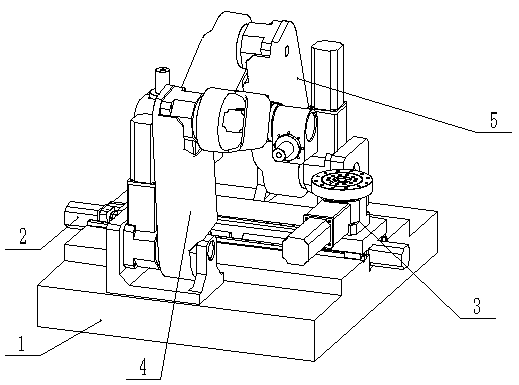

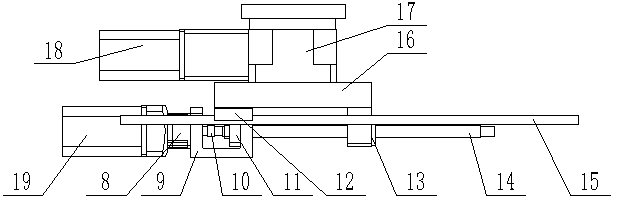

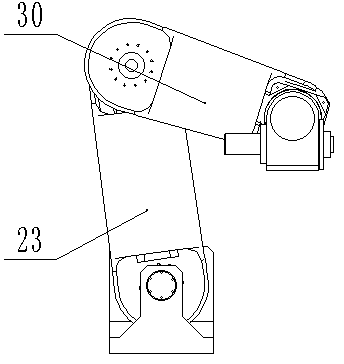

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the dual-station modular grinding and polishing robot consists of a bed module 1, a left workbench module 2, a right workbench module 3, a left manipulator module 4, and a right manipulator module 5.

[0029] Take the left workbench module 2 as an example to illustrate the implementation of the left and right workbench modules (because the right workbench module 3 and the left workbench module 2 are symmetrical, so it is omitted here). The left workbench module horizontal moving motor 19 front ends are connected with the left workbench module reducer 8, and the left workbench module reducer 8 is fixed on the left workbench module motor seat 9 by bolts. The left workbench module coupling 10 passes the left workbench module motor seat 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com