A kind of preparation method of tpu grating composite film with 2D anti-counterfeiting pattern

A technology of grating film and composite film, applied in the direction of copying/marking method, diffraction grating, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

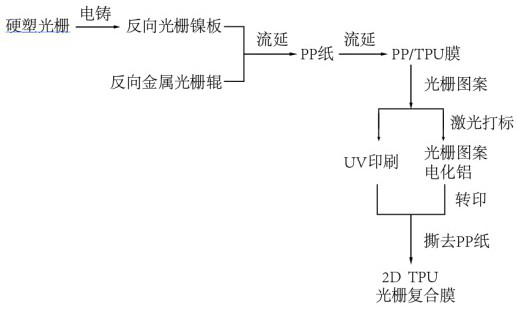

[0033] 1) Prepare PP / TPU grating film: the method for preparing PP / TPU grating film is to prepare PP / TPU grating film through hard plastic grating sheet;

[0034] The process steps of preparing PP / TPU grating film by hard plastic grating sheet include:

[0035] a. Copy the hard plastic grating sheet through the electroforming process to prepare the reverse grating nickel plate;

[0036] b. the grating nickel plate is installed on the roller of the casting production machine;

[0037] c. Through the casting production line, the PP raw material is melted and cast onto the grating nickel plate roller surface for cooling and shaping, and the PP paper with regularly arranged lenses on the surface is prepared;

[0038] d. Cast composite TPU again on PP paper to obtain PP / TPU grating film;

[0039] 2) Grating pattern design: According to the pattern application design of the convex lens arrangement rules of different grating types, make non-jumping anti-counterfeiting patterns;

...

Embodiment 2

[0046] 1) Prepare PP / TPU grating film: the method for preparing PP / TPU grating film is to prepare PP / TPU grating film through hard plastic grating sheet;

[0047] The process steps of preparing PP / TPU grating film by hard plastic grating sheet include:

[0048] a. Copy the hard plastic grating sheet through the electroforming process to prepare the reverse grating nickel plate;

[0049] b. the grating nickel plate is installed on the roller of the casting production machine;

[0050] c. Through the casting production line, the PP raw material is melted and cast onto the grating nickel plate roller surface for cooling and shaping, and the PP paper with regularly arranged lenses on the surface is prepared;

[0051] d. Cast composite TPU again on PP paper to obtain PP / TPU grating film;

[0052] 2) Grating pattern design: According to the pattern application design of the convex lens arrangement rules of different grating types, make non-jumping anti-counterfeiting patterns;

...

Embodiment 3

[0059] 1) Prepare PP / TPU grating film: the method for preparing PP / TPU grating film is to prepare PP / TPU grating film by metal grating roller;

[0060] The process steps of preparing PP / TPU grating film by metal grating roller include:

[0061] a. According to the number of grating lines required for production, the reverse metal grating roller with lenses arranged according to specific rules is processed by high-precision laser engraving equipment;

[0062]b. the metal grating roller is installed on the casting production machine;

[0063] c. Through the casting production line, the PP raw material is melted and cast to the surface of the metal grating roller for cooling and shaping, and the PP paper with regularly arranged lenses on the surface is prepared;

[0064] d. Cast composite TPU again on PP paper to obtain PP / TPU grating film;

[0065] 2) Grating pattern design: According to the pattern application design of the convex lens arrangement rules of different grating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com