Self-cleaning coarse grille belt conveying device, cleaning system and cleaning method

The technology of belt conveying and belt conveyor is applied in the field of self-cleaning coarse grid belt conveying device, which can solve the problems of increasing labor intensity of workers, harsh working environment, sticking to the belt, etc., so as to save labor intensity and labor cost, Automatic control of complete and tidy, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

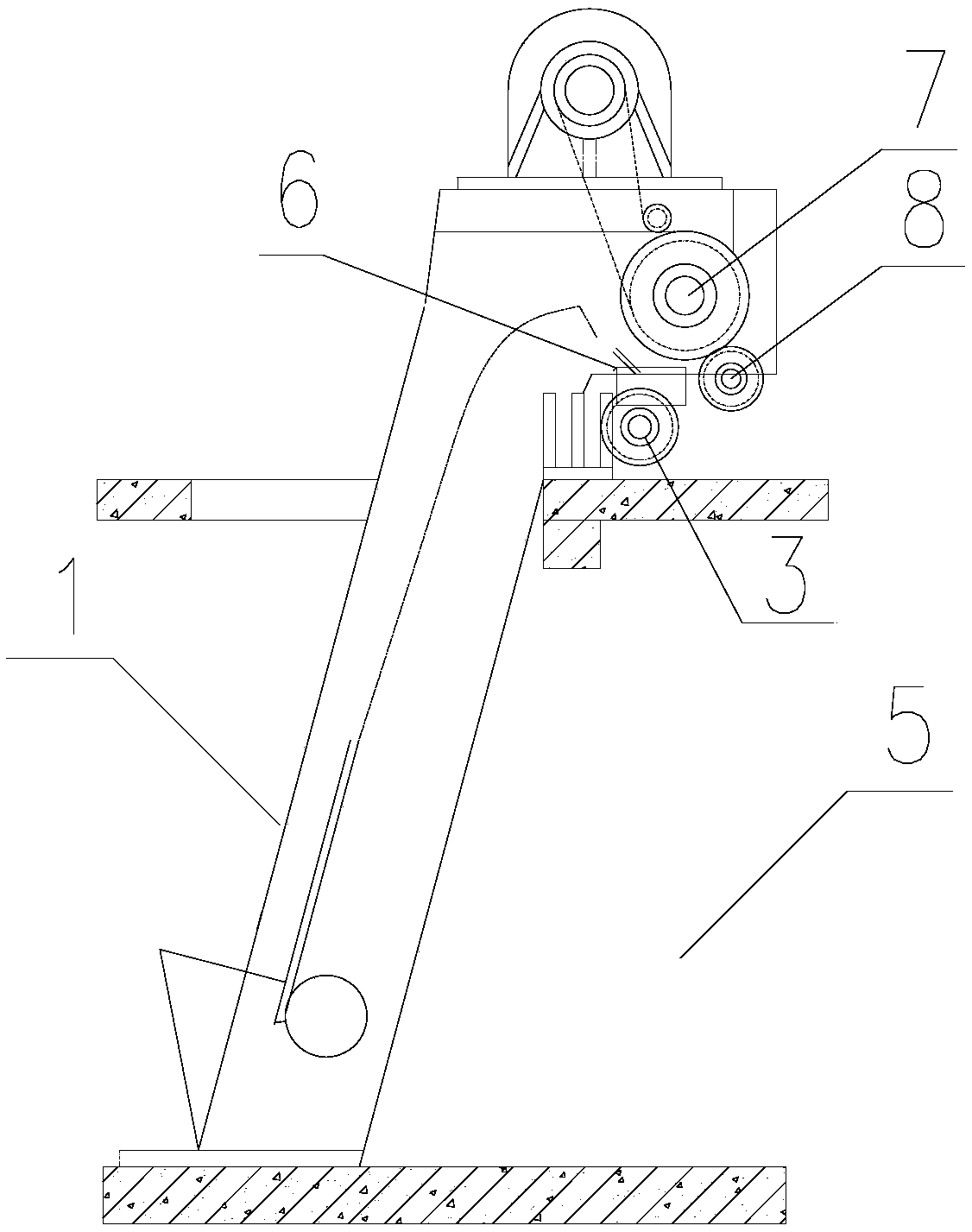

[0055] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0056] Coarse grid decontamination machine is a solid-liquid separation equipment that can continuously remove impurities in the fluid. It is indispensable in the production processes of urban sewage treatment, waterworks, power plant water inlets, textiles, food processing, papermaking, leather and other industries. The special equipment is the solid-liquid screening equipment commonly used in China at present.

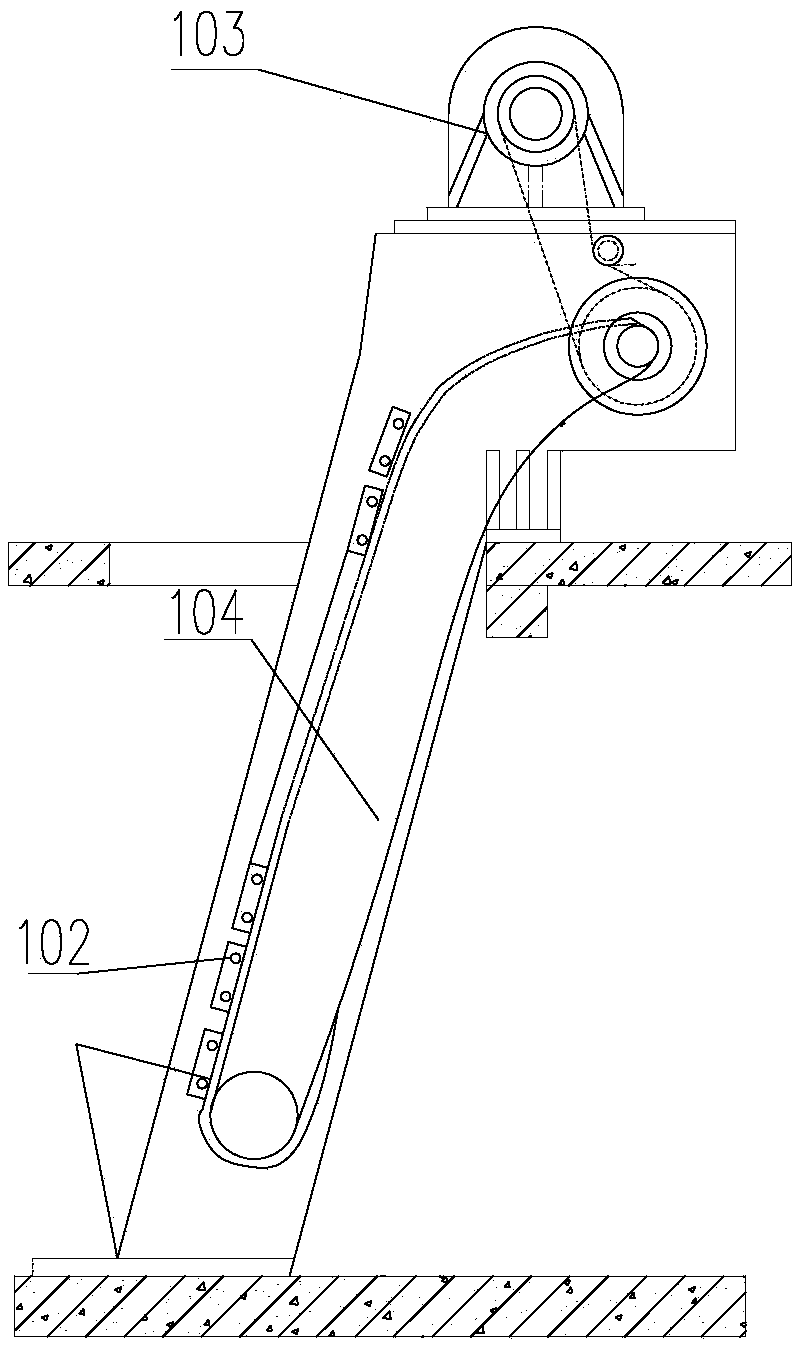

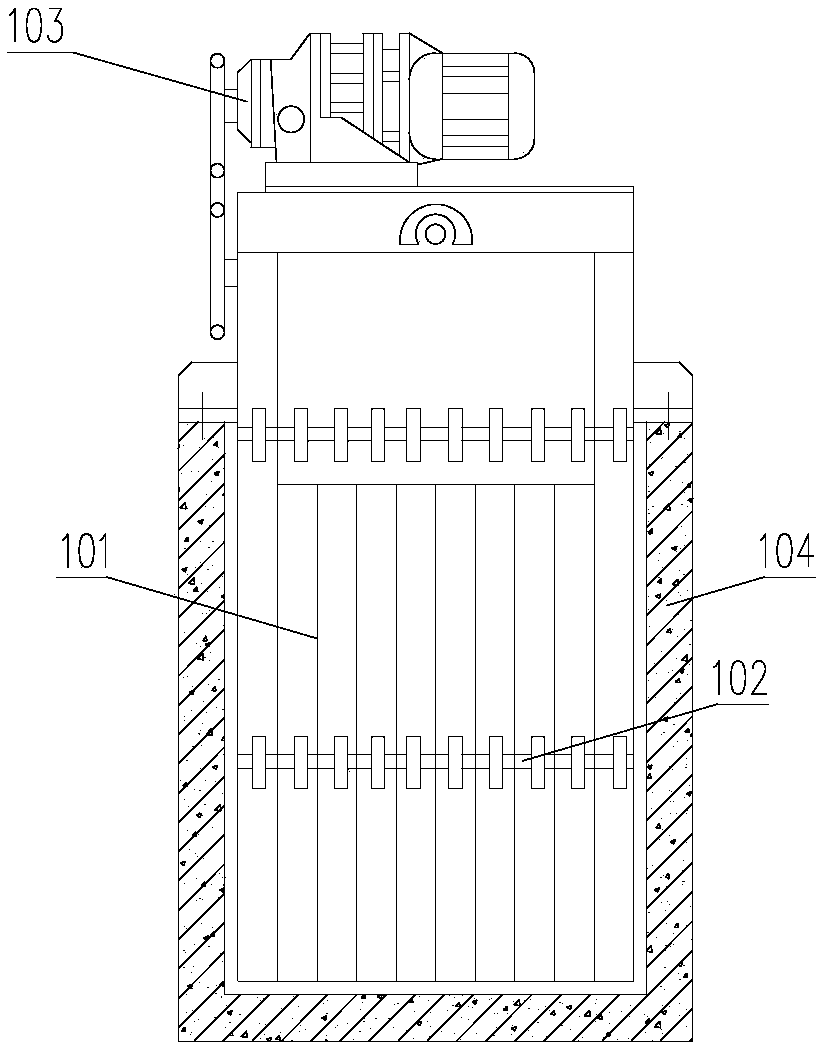

[0057] Such as figure 1 and figure 2 As shown, the coarse grid decontamination machine usually mainly includes coarse grid strips 101, decontamination rakes 102, screw conveyor 103 and frame 104, etc., the frame 104 is obliquely arranged in the decontamination tank, and the upper end of the frame 104 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com