Preparation method of sodium gualenate

A technology of sodium azulene sulfonate and sulfonating agent is applied in directions such as sulfonic acid preparation, sulfonate preparation, chemical instrument and method, and can solve the problems of high preparation cost, difficult to obtain raw materials, unfavorable large-scale production and application, etc., Achieve the effect of low production cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

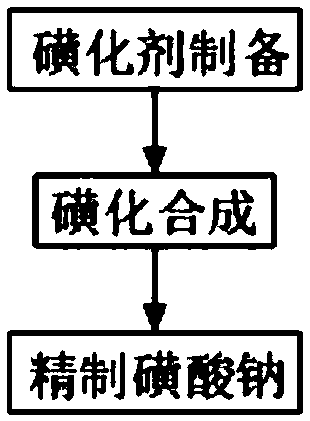

[0030] In order to solve this technical problem, the present invention proposes a kind of preparation method of sodium azulene sulfonate, please refer to figure 1 , for the preparation method of sodium azulene sulfonate that the first embodiment of the present invention proposes, comprise the steps:

[0031] (1) Preparation of sulfonating agent

[0032] Dichloroethane and triethyl phosphate are sequentially added into the reaction pot, sulfur trioxide is introduced under the condition of stirring, and the sulfonating agent is prepared at the first preset temperature.

[0033] In this step, sulfur trioxide is fed through a flow meter, and the above-mentioned first preset temperature is 0°C.

[0034] (2) Sulfonation synthesis: add guaiazulene and ethylene dichloride into the reaction pot, and add the sulfonating agent dropwise to In the reaction pot, after the dropwise addition is completed, the temperature is controlled to be lower than the third preset temperature for the fi...

Embodiment 2

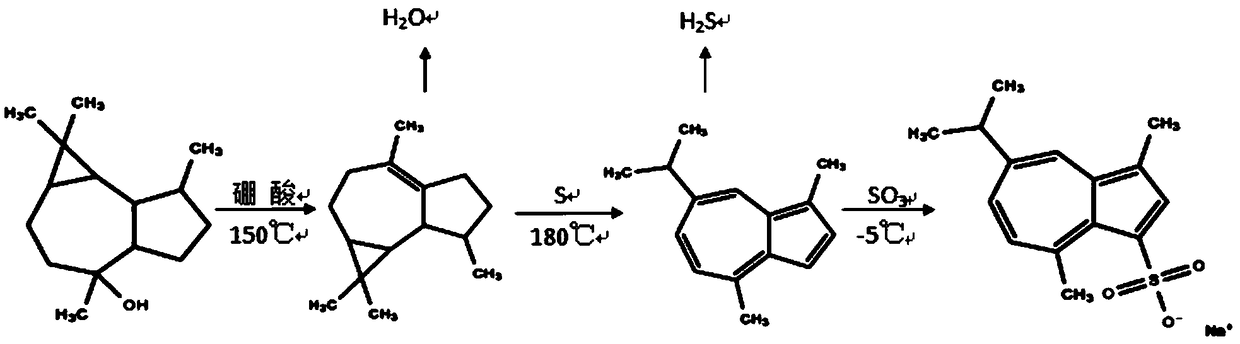

[0040] The preparation method of sodium azulene sulfonate proposed by the present invention is described in more detail below with a specific embodiment. Specifically, see figure 2 , the preparation method in this embodiment is specifically as follows:

[0041] (1), preparation of sulfonating agent

[0042] Put dichloroethane and triethyl phosphate into the reaction pot respectively, turn on the stirring device, and slowly introduce sulfur trioxide. Specifically, the sulfonating agent is prepared at 0° C. by feeding it through a flow meter according to the ratio for use in the next process.

[0043] (2), sulfonation synthesis

[0044] Put guaiazulene and dichloroethane into the reaction pot in proportion, turn on the stirring device to stir, and when the temperature of the material is -5°C, vacuum pump the sulfonating agent prepared in the above steps, and slowly introduce it at a controlled speed , Keep the reaction for half an hour in an environment lower than 10°C afte...

Embodiment 3

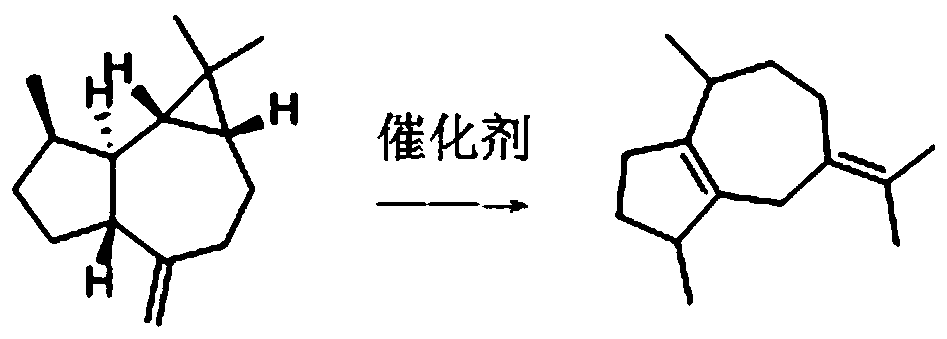

[0052] In the present invention, also propose a kind of preparation method of guaiacene, please refer to image 3 , including the following steps:

[0053](1) Turn on the vacuum equipment of the hydrogenation reactor, open the valve of the suction port, and inhale the orangerene into the reactor. Specifically, the raw material barrel is placed on the electronic scale, and the amount of raw material added is calculated through the reading change. After the suction is completed, turn off the vacuum equipment, turn on the stirring under normal pressure, start the suction port above the reactor, open the feed port above the reactor, add Raney nickel, close the feed port after feeding, and close the suction port above the reactor. tuyere.

[0054] (2) After the feeding process is over, replace the air in the kettle with hydrogen, then inject hydrogen into the reactor to 0.3MPa, turn on the steam for heating, control the temperature in the reactor to 130°C, and keep the hydrogen i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com