Rare earth long-afterglow light emitting powder, preparation method thereof, waterborne energy storage type rare earth long-afterglow light emitting coating and preparation method thereof

A long afterglow luminescent powder and long afterglow luminescence technology, which is applied in luminescent coatings, luminescent materials, chemical instruments and methods, etc., can solve the problems of poor water resistance and short afterglow time, and achieve the effect of improving afterglow life and excellent fluorescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

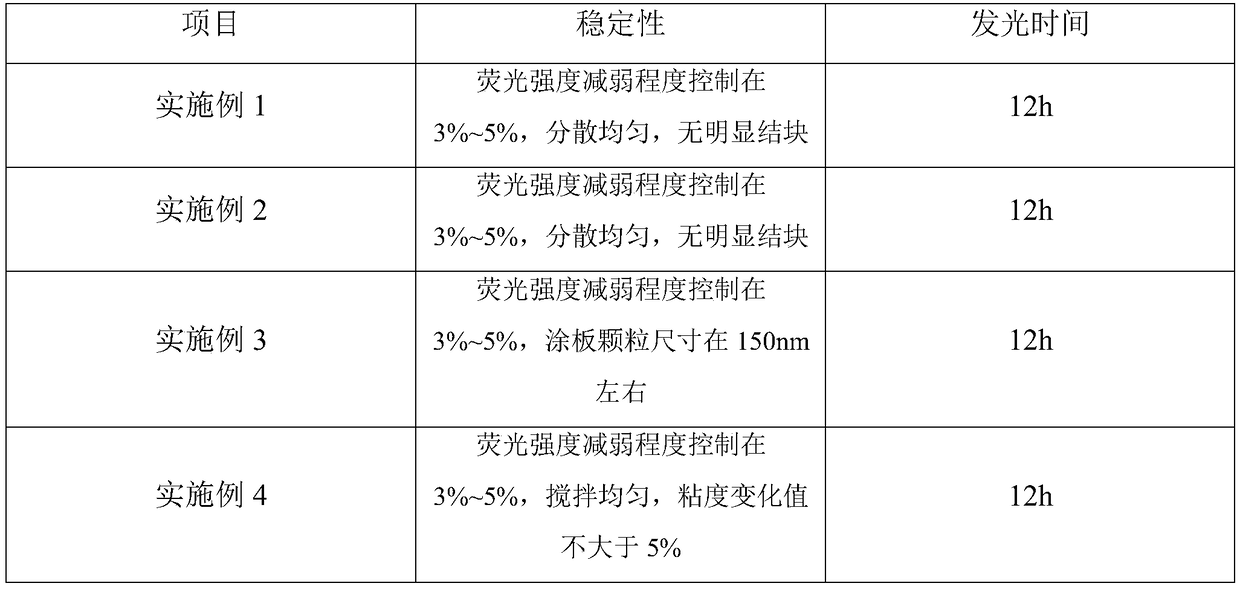

Embodiment 1

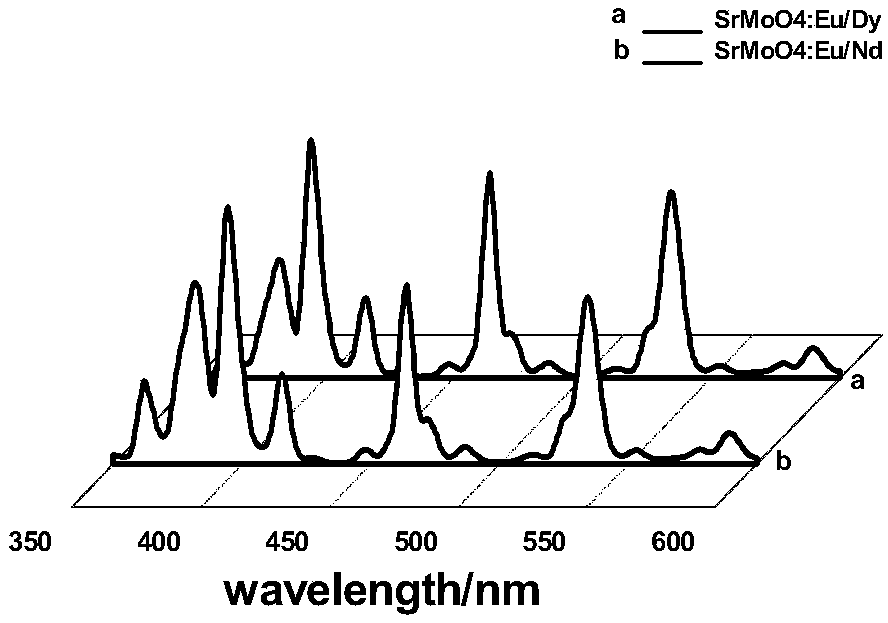

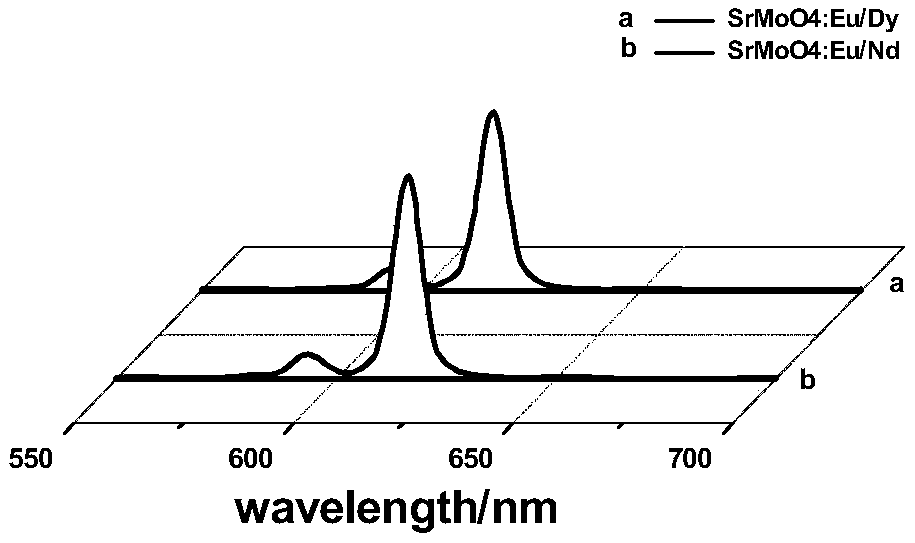

[0069] The rare earth long afterglow luminous powder of this embodiment has a molecular formula of SrMoO 4 :Eu 0.02 : Dy 0.03 , the particle size is 100-200nm.

[0070] The preparation method of the rare earth long-lasting luminescent powder of this embodiment includes the following steps:

[0071] 1) Weigh 0.1mol Eu 2 o 3 and 0.1mol Dy 2 o 3 , were dissolved in excess concentrated nitric acid, respectively, diluted with deionized water to a concentration of 0.1mol / L Eu(NO 3 ) 3 solution and 0.1mol / L Dy(NO 3 ) 3 solution, spare;

[0072] 2) According to the stoichiometric ratio of SrMoO 4 :Eu 0.02 : Dy 0.03 , followed by adding 2mol / L of Sr(NO 3 ) 2 Solution 5mL and Eu(NO 3 ) 3 Solution 2ml, Dy(NO 3 ) 3 Solution 3mL, stirred at constant temperature for 0.5h until uniform, to obtain a mixed solution; 25ml concentration of 2mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 O aqueous solution was slowly added dropwise to the above mixed solution with a burette until the mixe...

Embodiment 2

[0079] The difference between this embodiment and Embodiment 1 is that the Dy element in Embodiment 1 is replaced by Nd.

Embodiment 3

[0081] The rare earth long afterglow luminous powder of this embodiment has a molecular formula of SrMoO 4 :Eu 0.02 :Nd 0.03 , the particle size is 100-200nm.

[0082] The preparation method of the rare earth long-lasting luminescent powder of this embodiment includes the following steps:

[0083] 1) Weigh 0.1mol Eu 2 o 3 and 0.1mol Nd 2 o3 , were dissolved in excess concentrated nitric acid, respectively, diluted with deionized water to a concentration of 0.1mol / L Eu(NO 3 ) 3 solution and 0.1mol / L Nd(NO 3 ) 3 solution, spare;

[0084] 2) According to the stoichiometric ratio of SrMoO 4 :Eu 0.02 :Nd 0.03 , followed by adding 2mol / L of Sr(NO 3 ) 2 Solution 4mL and Eu(NO 3 ) 3 Solution 2mL, Nd(NO 3 ) 3 Solution 3mL, stirred at constant temperature for 0.5h until uniform, to obtain a mixed solution; 2mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 28ml of O aqueous solution was slowly added dropwise to the above mixed solution with a burette until the mixed solution appeare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com