High-speed centrifugal spinning device for preparing nanofibers

A technology of nanofiber and high-speed centrifugation, which is applied in fiber processing, textile and papermaking, and melting of filament raw materials. It can solve the problems of low production efficiency, conductivity constraints, and high cost, and achieve high production efficiency without conductivity. The effect of constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

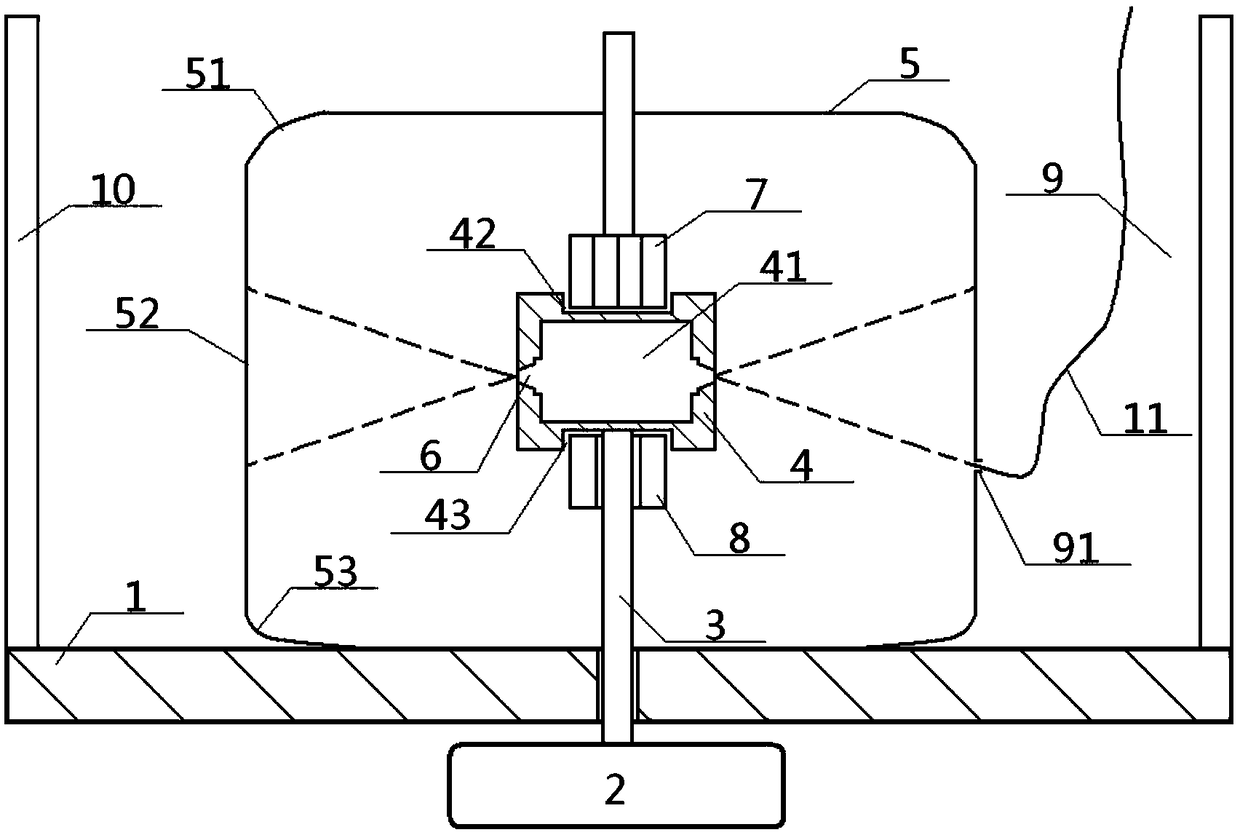

[0042] see Figure 1 to Figure 3 , a high-speed centrifugal spinning device for preparing nanofibers, comprising a filling rotor 4, a rotating shaft 3 and a collecting device 5, the filling rotor 4 communicates with a nozzle 6, the inside of the filling rotor 4 is filled with a polymer, and the filling rotor The bottom of 4 is connected with the rotating shaft 3, and a collecting device 5 is arranged around the rotor 4;

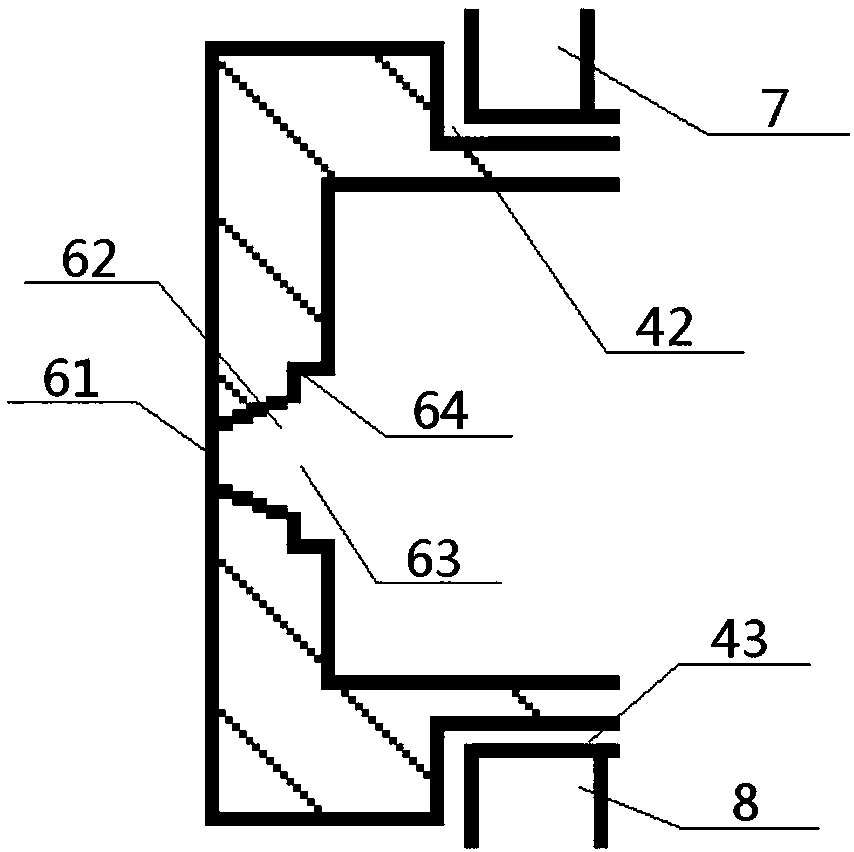

[0043] The inside of the material-filling rotor 4 is provided with a material-filling cavity 41, and a polymer is arranged in the material-filling cavity 41, and a nozzle 6 communicating with the material-filling cavity 41 is provided on the side wall of the material-filling rotor 4, and the material-filling rotor 4 An upper heater 7 and a lower heater 8 are arranged on the upper and lower sides respectively, the bottom of the rotor 4 is connected to the top of the rotating shaft 3, and the bottom of the rotating shaft 3 passes through the base 1 and is conne...

Embodiment 2

[0046] Basic content is the same as embodiment 1, the difference is:

[0047] The top and the bottom of the rotor 4 are respectively provided with a top groove 42 and a bottom groove 43, the top groove 42 is provided with the bottom of the upper heater 7, and the top of the upper heater 7 is extended to the top of the material. Directly above the rotor 4 , the bottom groove 43 is provided with the top of the lower heater 8 , and the bottom of the lower heater 8 extends down to directly below the rotor 4 . The lower heater 8 is sleeved on the outer wall of the rotating shaft 3 , and the junction of the rotating shaft 3 and the material-filling rotor 4 is set higher than the top of the lower heater 8 .

Embodiment 3

[0049] Basic content is the same as embodiment 1, the difference is:

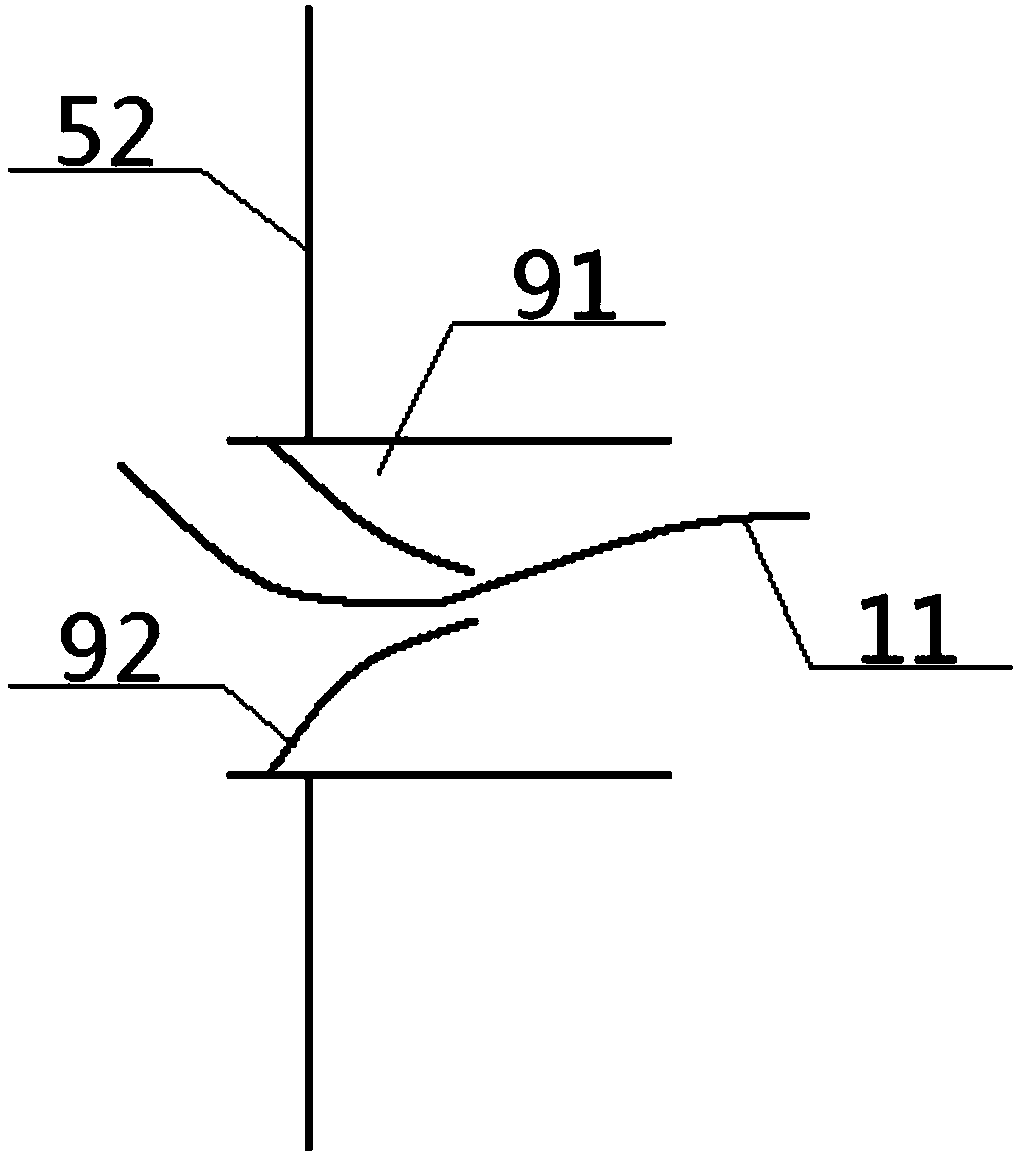

[0050] The collection device 5 is a cylindrical structure with openings at both ends. The side enclosure of the collection device 5 includes an upper inner arc edge 51, a middle vertical edge 52 and a lower inner arc edge 53. The upper inner arc edge 51 passes through the middle vertical edge 52, The lower inner arc edge 53 is then connected to the top surface of the base 1, and the upper inner arc edge 51 and the lower inner arc edge 53 are both inner turning structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com