Pipeline seismic mitigation and absorption device and construction method thereof

A construction method and vibration reduction and isolation technology, applied in the direction of pipeline supports, pipeline systems, springs/shock absorbers, etc., can solve the problems of uneven force on the pier, poor energy consumption effect, and uneconomical, etc., to reduce water flow vibration The effect of easy installation and disassembly, and the effect of restoring normal functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

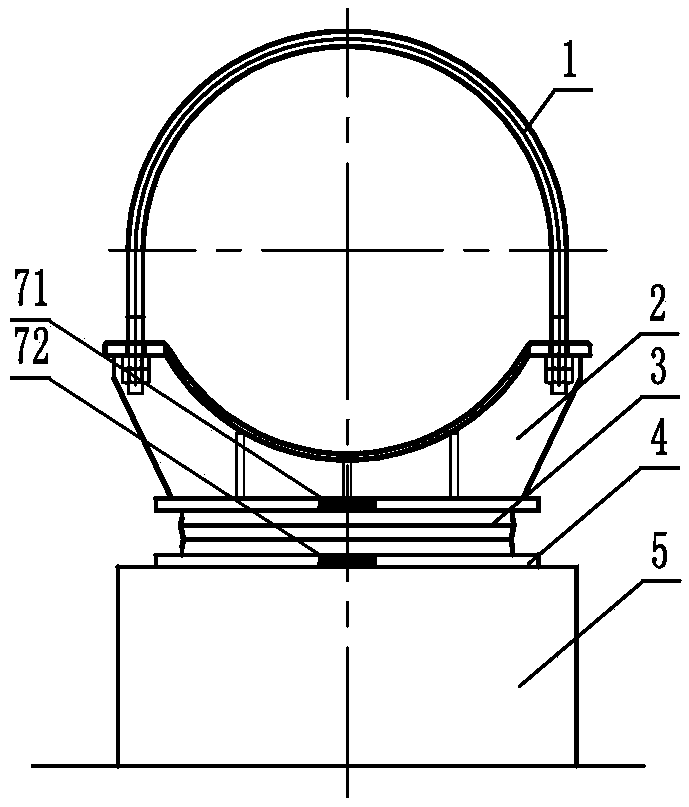

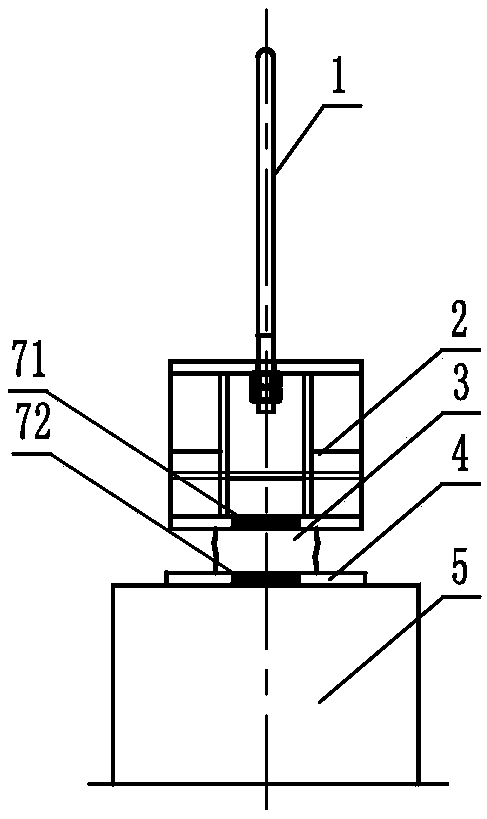

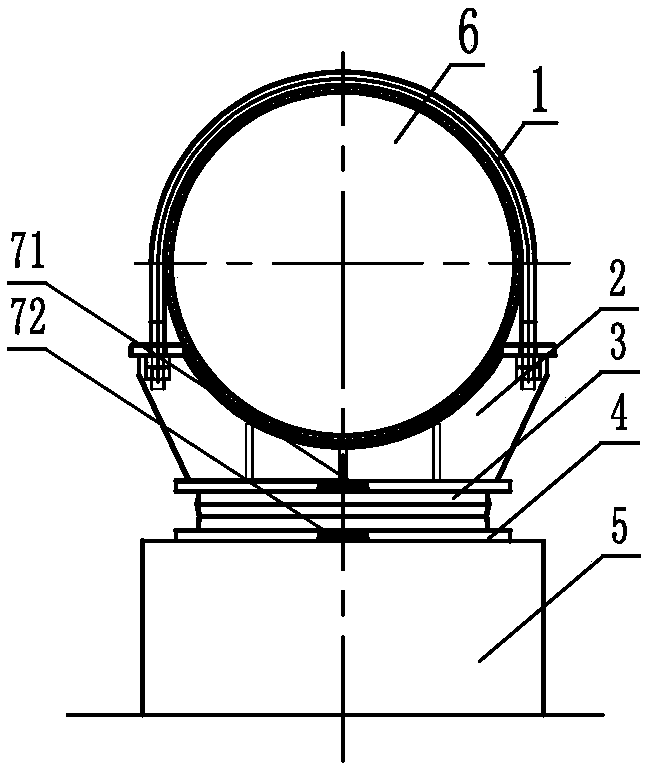

[0080] The pipeline vibration isolation device includes a pipeline support 5 and a lower connecting piece 4 installed on the pipeline support, an energy dissipation component 3, an upper pipe support 2 and a structural hoop 1, and the lower connecting piece 4 is fixed to the pipeline support 5 connection, the upper pipe support 2 and the lower connecting piece 4 are connected with the energy dissipation part 3, the upper part of the upper pipe support 2 is connected with the structural hoop 1 and the pipe 6 is fixed through the structural hoop, and the pipe support is either a concrete pier or a steel frame;

[0081] Displacement scales are installed on the longitudinal side of the pipeline shock-isolation device and its adjacent lateral side, including an upper displacement scale 71 and a lower displacement scale 72. The upper displacement scale is installed on the upper pipe support 2, and the lower displacement scale is installed on the lower part. on the connector;

[008...

Embodiment 2

[0086] A pipe shock absorber, the structure of which is basically the same as that of Embodiment 1, the difference is that the upper pipe holder 2 is a split pipe holder, and the split pipe holder includes a pipe holder seat 22 and a movable bracket 21 , The pipe bracket and the movable bracket are matched by a rotating pair, the rotating pair is an arc surface or a spherical surface with the same radian, and the pipe bracket is provided with a limit plate for limiting the lateral movement of the movable bracket.

[0087] Now the upper displacement scale is installed on the pipe holder 22, and the laser displacement sensor is connected on the pipe holder 22.

[0088] This embodiment is used for the support and fixation of pipelines laid on slopes (see attached Figure 6-10 ).

Embodiment 3

[0090] A pipeline shock-proof and isolation device, the structure of which is basically the same as that of Embodiment 1, the difference is that the pipeline shock-proof and isolation device is equipped with an intelligent displacement acquisition system, and the intelligent displacement acquisition system includes a collector 8, a laser displacement sensor 10 and reflector 11, the laser displacement sensor 10 and the reflector 11 are installed on the longitudinal side and the lateral side of the displacement scale installed in the pipeline shock isolation device at the same time, the laser displacement sensor is connected on the upper pipe support 2, and the reflector 11 is connected to the lower connector 4 through the reflective plate positioning frame 12, and the reflective plate 11 is opposite to the position of the laser displacement sensor 10, and the laser displacement sensor 10 is connected to the acquisition instrument 8 through the connection line 9, and the acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com