Steam generator and manufacturing method thereof

A technology of steam generator and economizer, which is applied in the direction of steam generation, steam boiler, steam boiler accessories, etc., which can solve the problems of water shortage, intermittent steam production, burst pipe, etc., to ensure saturation purity, stable operation, and easy normal use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

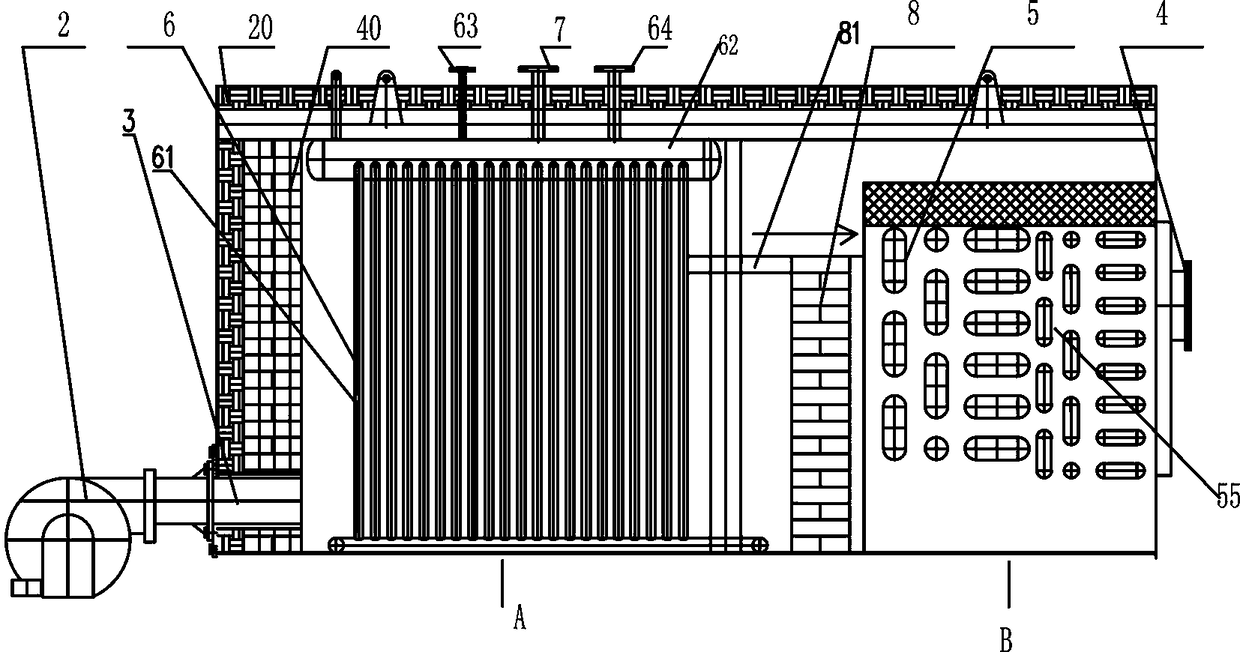

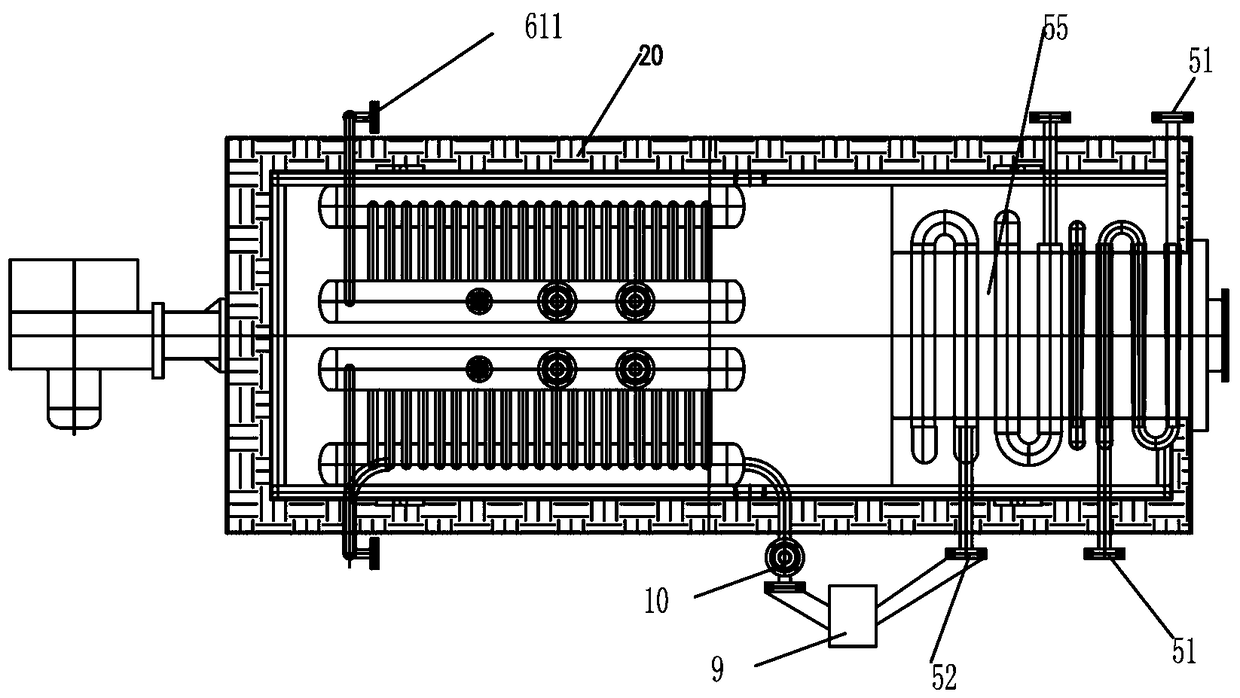

[0032] This embodiment provides a steam generator, which includes a tank body 1, a burner 2 and a steel frame arranged in the tank body 1, and the opposite sides of the tank body 1 are respectively provided with air inlets 3 communicating with the burner and the chimney mouth 4, an economizer 5 communicating with the chimney mouth 4 is arranged in the tank body 1 on the side of the chimney mouth 4, and a preheater 6 is arranged in the tank body 1 on the side of the air inlet; The economizer 5 is provided with a water inlet 51 and a water outlet 52, the preheater 6 is provided with a preheating pipe 61, the water outlet 52 of the economizer 5 communicates with the preheating pipe 61, and the tank body 1 is provided with a main steam valve 7 communicating with the preheating pipe 61. Water at normal temperature enters the economizer 5 through the water inlet 51 on the economizer 5, and then enters the preheater 6 through the water outlet 52. During the whole process, since one s...

Embodiment 2

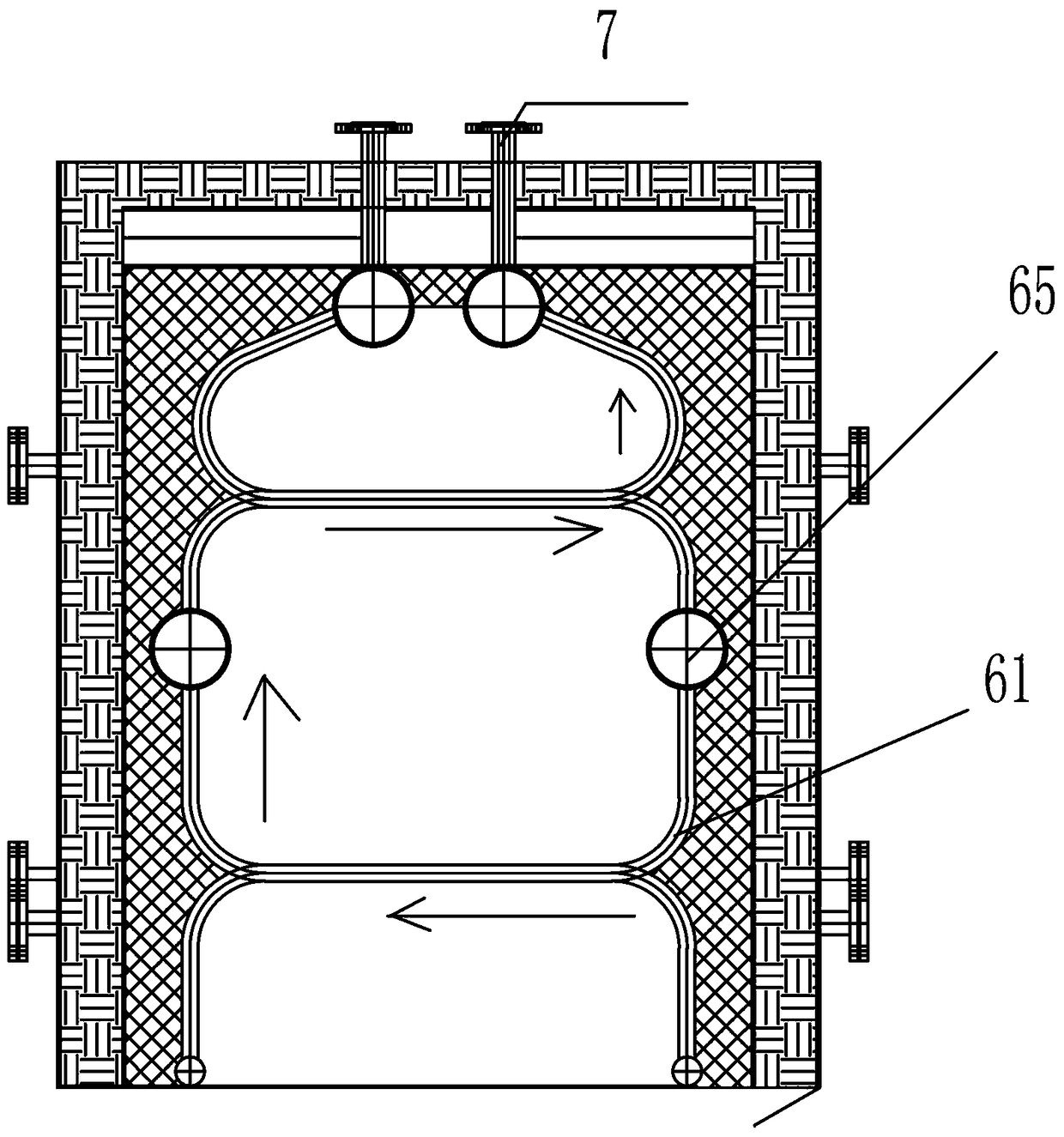

[0034]Embodiment 2 is further defined on the basis of Embodiment 1: a smoke-folding wall 8 is provided between the preheater 6 and the economizer 5, and a smoke-folding wall 8 is reserved between the top of the smoke-folding wall 8 and the top of the tank body 1 There is a flue gas passage, and a smoke folding baffle 81 connected to the preheating pipe 61 is arranged horizontally on the top of the smoke folding wall 8 , and the flue gas in the preheater 6 flows along the flue gas passage. The hot gas used in the preheater by the smoke-folding wall 8 can be blocked by the smoke-folding wall 8 and then flow back into the space of the preheater 6 for heating. Using the function of the smoke-folding baffle 81, the hot gas rises to the bottom of the preheater 6 The upper part enters the economizer 5 through the flue gas channel, which improves the utilization rate of the hot gas, avoids the heat loss caused by the direct entry of the hot gas into the economizer 5, and improves the e...

Embodiment 3

[0036] Embodiment 3 is further defined on the basis of Embodiment 1: the preheater 6 includes two preheating pipes 61, and the two preheating pipes 61 are arranged in an S-shaped curve from bottom to top. The preheating pipes cross each other and are not communicated. The inlet of the lower part of the preheating pipe 61 communicates with the water outlet of the economizer 5 . The steam storage package 62. The hot water in the preheating pipe 61 moves from bottom to top to the steam storage package 62 on the upper part of the preheating tube 61 while being heated. When it is in the steam storage package 62, it has been directly usable steam, and the steam storage package 62 is set There are pressure gauges 63 and safety valves 64 for measuring pressure to avoid potential safety hazards caused by excessive pressure, and a main steam valve for connecting to the outside and using steam is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com