Automatic monitoring system and monitoring method for quality change of energetic material

An automatic monitoring and quality change technology, which is applied in the direction of material weighing, material analysis, measuring devices, etc., can solve the problems of complicated operation steps, large manpower and time cost, and low degree of automation, so as to achieve constant temperature heating and save manpower , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

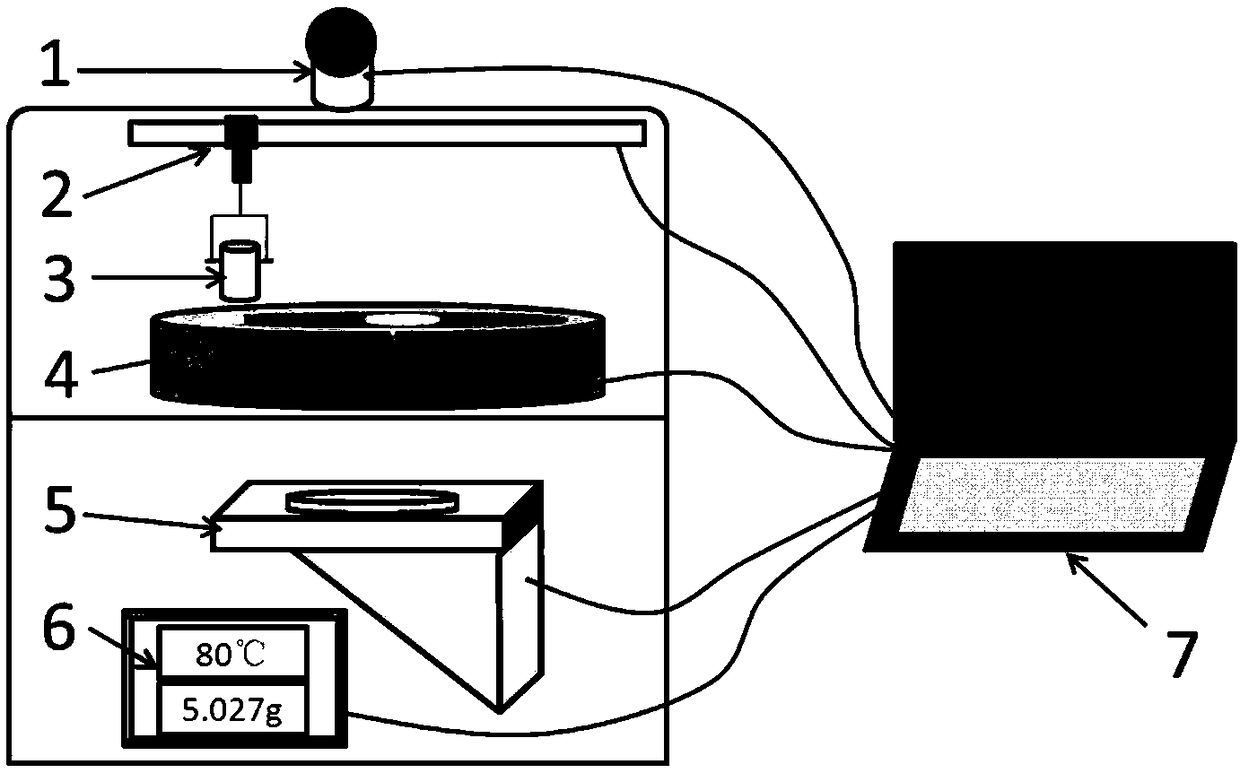

[0028] Taking the mass change of 6 powder samples of 200mg energetic material RDX (RDX) at 120°C for 90 days as an example to illustrate the realization method of the present invention, the steps are as follows:

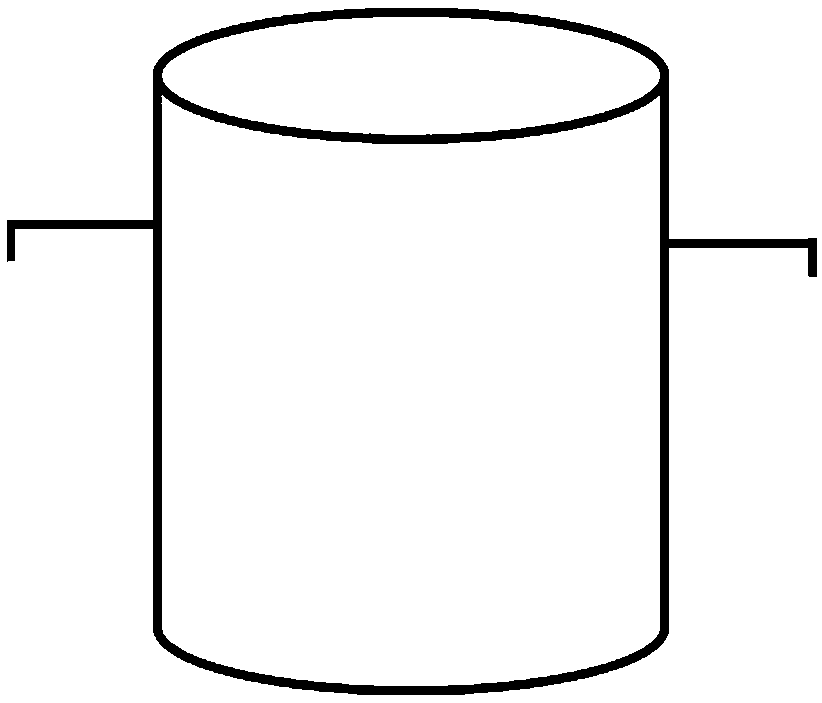

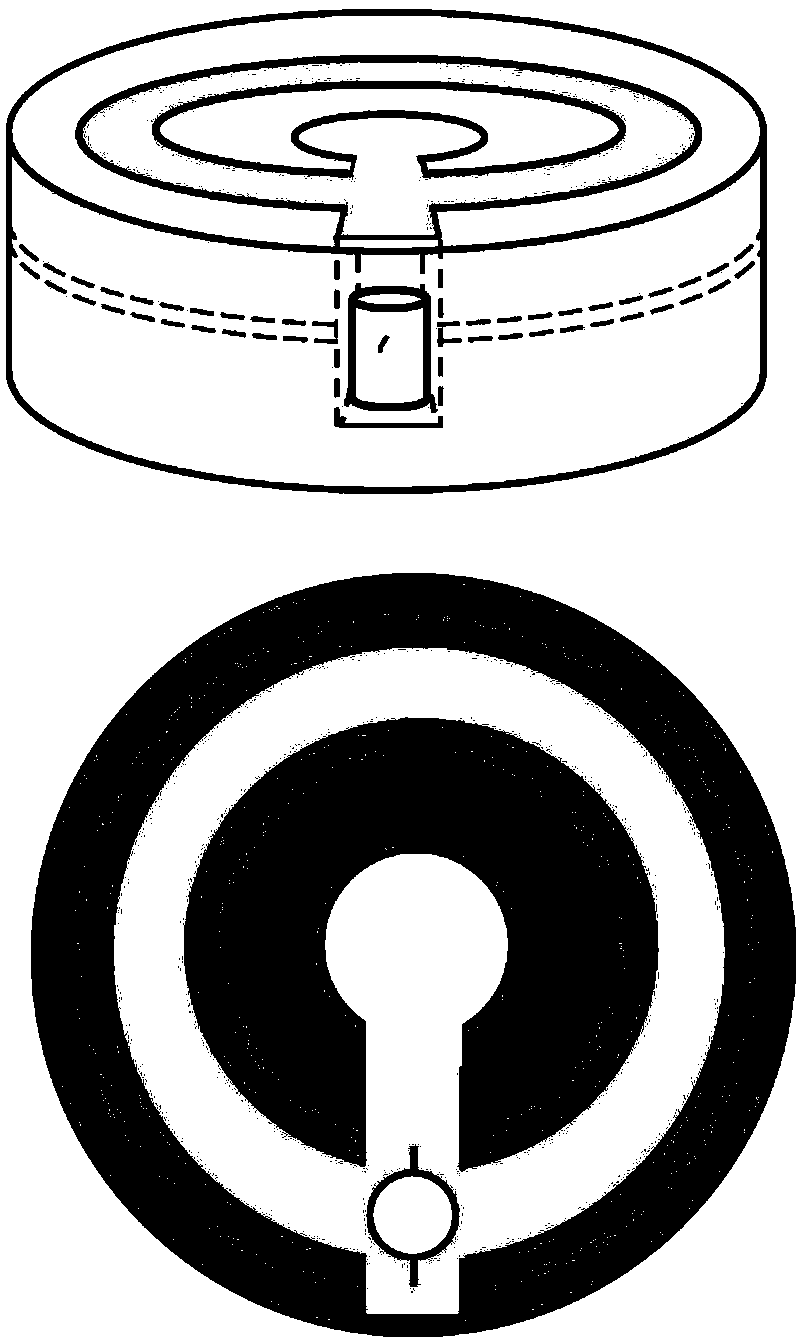

[0029] (1) Select 6 sample cells with a diameter of 20 mm and a height of 50 mm, number them sequentially, and carry out mass weighing, and enter the weighing results into the computer software;

[0030] (2) Set the constant temperature of the heating constant temperature device in the computer software to 120°C, the heating rate to 5°C / min, the automatic sampling frequency to 3 days / time, and the number of times to use 30 times, and the alarm temperature of the alarm system is set to 125°C;

[0031] (3) Add 200 mg of RDX samples to 6 sample containers respectively, and when the temperature of the heating constant temperature device is constant at 120°C, put the sample containers into the heating constant temperature device in turn;

[0032] (4) Control the mechanical ...

Embodiment 2

[0035] Taking the mass change of four Ф10×10 energetic material polymer bonded explosive (PBX) grains at 100°C for 60 days as an example to illustrate the implementation method of the present invention, the steps are as follows:

[0036] (1) Select 4 sample cells with a diameter of 20 mm and a height of 50 mm, number them sequentially, and carry out mass weighing, and enter the weighing results into the computer software;

[0037] (2) Set the constant temperature of the heating constant temperature device in the computer software to 100°C, the heating rate to 3°C / min, the automatic sampling frequency to 2 days / time, and the number of times to use 30 times, and the alarm temperature of the alarm system is set to 110°C;

[0038] (3) Add a Ф10×10 PBX powder column to each of the four sample pools. When the temperature of the heating thermostat is constant at 100°C, put the sample containers into the heating thermostat in turn;

[0039] (4) The robot arm and weighing system of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com