Insulating porous layer for non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, batteries, lithium batteries, etc., can solve the problems of battery characteristics degradation, electrode and spacer position deviation, battery characteristics are not high enough, etc., to achieve high air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] [Embodiment 1: Insulating Porous Layer for Nonaqueous Electrolyte Secondary Battery]

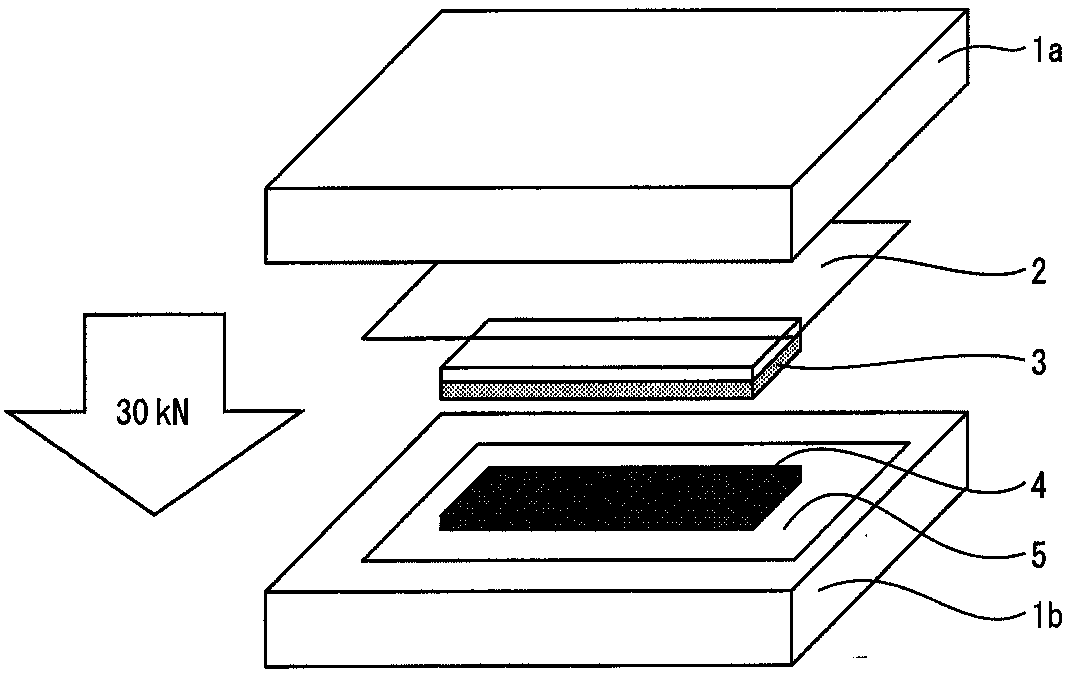

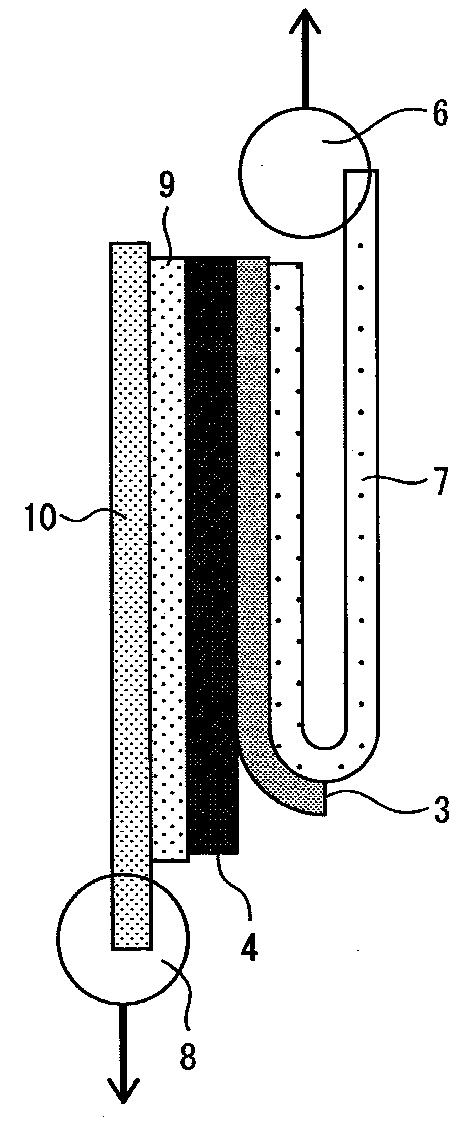

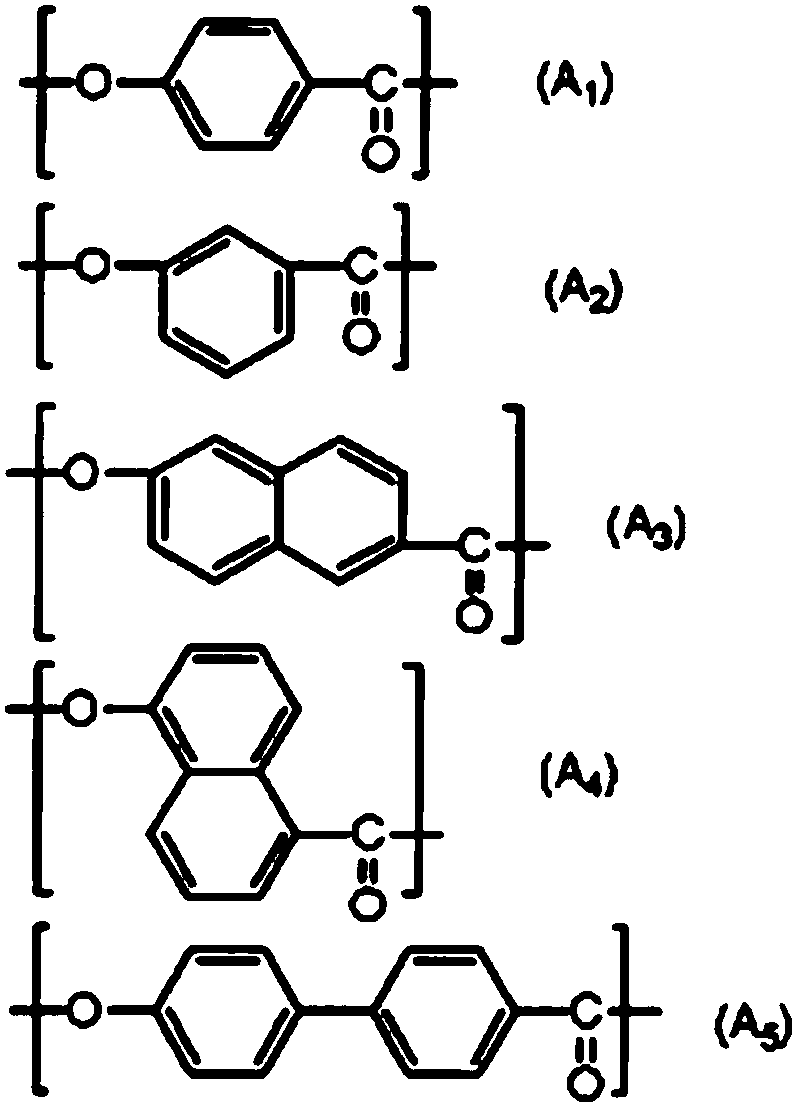

[0028] The insulating porous layer for a non-aqueous electrolyte secondary battery (hereinafter also simply referred to as "porous layer") according to Embodiment 1 of the present invention is for covering the porous layer constituting the laminated separator for a non-aqueous electrolyte secondary battery. An insulating porous layer for a non-aqueous electrolyte secondary battery on at least one side of the substrate, which contains a thermoplastic resin and has a porosity of 25% or more and 80% or less, at 25°C, 30kN, 1 minute x 2 times Under the conditions, the peel strength when crimping with the electrode for non-aqueous electrolyte secondary battery containing electrode active material, conductive agent and binder in the mass ratio of 92:2.7:5.3 is greater than 0N / m and 2.0N / m below m.

[0029] An electrode for a nonaqueous electrolyte secondary battery containing an electrode ...

Embodiment approach 2

[0158] [Embodiment 2: Laminated separator for non-aqueous electrolyte secondary battery]

[0159] The laminated separator for nonaqueous electrolyte secondary batteries according to Embodiment 2 of the present invention includes a polyolefin porous film and the porous layer according to Embodiment 1 of the present invention. It is preferable that the laminated spacer for a non-aqueous electrolyte secondary battery according to Embodiment 2 of the present invention includes a polyolefin porous film and the separator according to Embodiment 1 of the present invention laminated on at least one side of the polyolefin porous film. porous layer.

[0160]A laminated spacer for a nonaqueous electrolyte secondary battery according to an embodiment of the present invention is provided with the insulating porous layer for a nonaqueous electrolyte secondary battery according to an embodiment of the present invention so as to be able to connect with the battery. The air permeability linke...

Embodiment approach 3

[0183] [Embodiment 3: Member for Nonaqueous Electrolyte Secondary Battery, Embodiment 4: Nonaqueous Electrolyte Secondary Battery]

[0184] The member for non-aqueous electrolyte secondary batteries according to Embodiment 3 of the present invention is to sequentially arrange the positive electrode, the insulating porous layer for non-aqueous electrolyte secondary batteries according to Embodiment 1 of the present invention, or an embodiment of the present invention. The non-aqueous electrolyte secondary battery according to Embodiment 2 is formed by laminating a separator and a negative electrode.

[0185] The nonaqueous electrolyte secondary battery according to Embodiment 4 of the present invention includes the insulating porous layer for a nonaqueous electrolyte secondary battery according to Embodiment 1 of the present invention, or the nonaqueous electrolyte secondary battery according to Embodiment 2 of the present invention. A laminated separator for aqueous electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com