Alkali-developable photosensitive resin composition, dry film and cured product, and printed circuit board

A photosensitive resin, alkali developing technology, used in printed circuit parts, optics, photography, etc., can solve the problems of chemical tin plating resistance and insufficient chemical gold plating resistance of the resin composition, and achieve the effect of excellent chemical gold plating resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

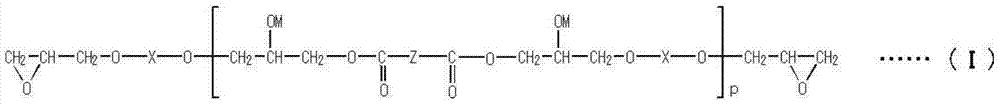

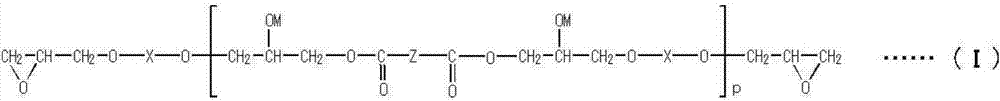

Method used

Image

Examples

Embodiment

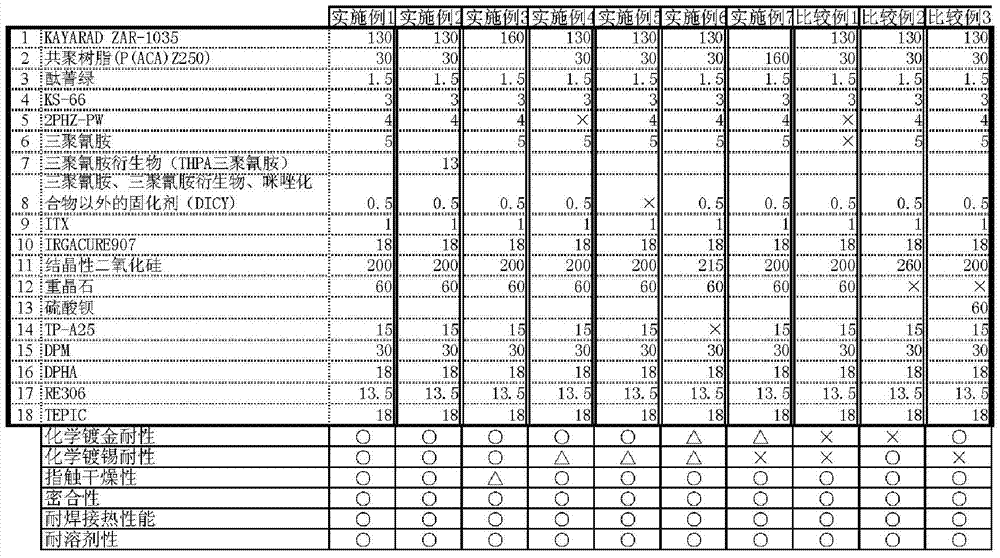

[0121] Substrate production conditions:

[0122] According to the composition shown in Table 1, each component was mixed with the dissolver, and it was made to disperse uniformly, and curable resin composition was obtained. Using a 100-mesh polyester screen, the composition was coated on the entire surface with a thickness of 20 to 30 μm on a patterned copper through-hole printed circuit board by a screen printing method. Next, the coating film was dried for 30 minutes using a hot air circulation drying oven at 80° C., and tests for dryness to touch and developability were performed by the test method and evaluation method described later.

[0123] Next, a negative film having a resist pattern is closely bonded to the coating film, and an ultraviolet exposure device (manufactured by ORCMANUFACTURING CO., LTD., model HMW-680GW) is used to irradiate ultraviolet rays (exposure amount: 300mJ / cm 2 ), followed by developing for 60 seconds with 1 wt % sodium carbonate aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com