A kind of preparation method of reverse osmosis composite non-woven fabric

A non-woven fabric and reverse osmosis technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of not being able to make good use of the water-repellent properties of kapok and the high pressure of environmental protection, so as to achieve weakened reverse osmosis ability and good conductivity. The effect of clear paths and channels, and good water-conducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

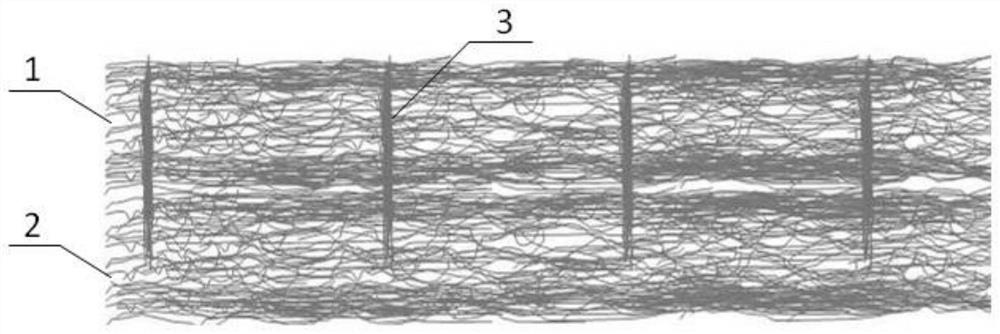

[0033] like Figure 1-3As shown, the present embodiment discloses a preparation method of a reverse osmosis composite nonwoven fabric, comprising the following steps: forming a double-layer fiber web layer of kapok and modal through web laying, and the thickness of the kapok fiber web layer 1 accounts for the total thickness of the nonwoven fabric The thickness of the modal fiber web layer 2 accounts for 0.65% of the total thickness of the nonwoven fabric; the double-layer fiber web layer is transported through the mesh curtain at a speed of 5m / min for mechanical reinforcement. The mechanical reinforcement method is spunlace reinforcement, and the mechanical reinforcement direction is from The kapok fiber net layer 1 is reinforced towards the modal fiber net layer 2, and the first kapok fiber bundle 3 in the kapok fiber net layer 1 is embedded in the modal fiber net layer 2, and the length of the first kapok fiber bundle 3 embedded section is modal fiber net layer 2 0.31 of th...

Embodiment 2

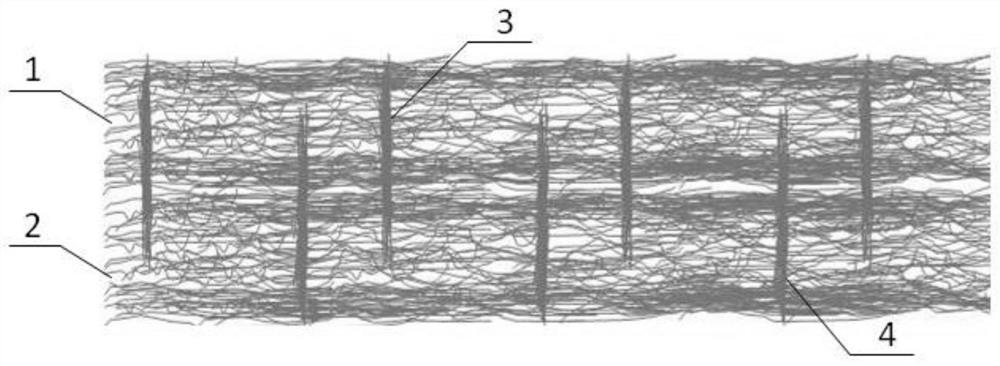

[0036] This embodiment discloses a method for preparing a reverse osmosis composite nonwoven fabric, comprising the following steps: forming a double-layer fiber web layer of kapok and modal through laying, the thickness of the kapok fiber web layer accounts for 0.4 of the total thickness of the nonwoven fabric, and the modal The thickness of the fiber web layer accounts for 0.6 of the total thickness of the nonwoven fabric; the double-layer fiber web layer is conveyed through the mesh curtain at a speed of 9m / min for mechanical reinforcement. The mechanical reinforcement method is spunlace reinforcement, and the mechanical reinforcement direction is from the kapok fiber web layer to The modal fiber net layer is reinforced, and the first kapok fiber bundle in the kapok fiber net layer is embedded in the modal fiber net layer, and the length of the first kapok fiber bundle embedded section is 0.4 of the thickness of the modal fiber net layer; The layered fiber web is reinforced ...

Embodiment 3

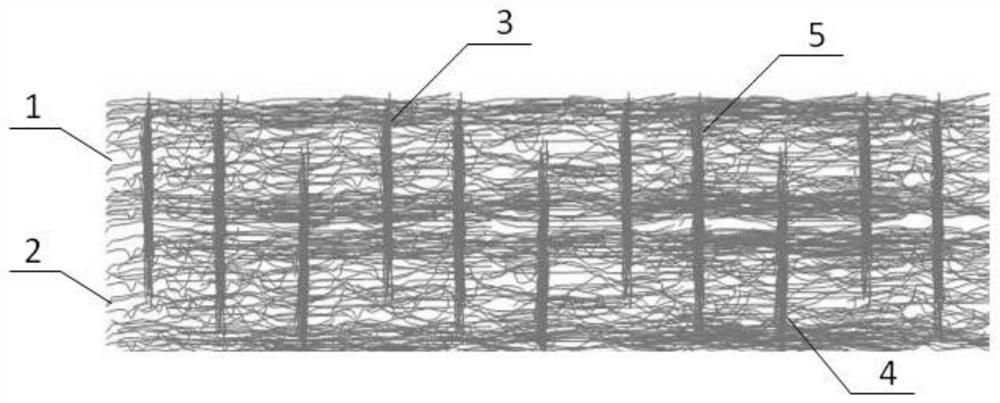

[0039] This embodiment discloses a method for preparing a reverse osmosis composite nonwoven fabric, comprising the following steps: forming a double-layer fiber web layer of kapok and modal through web laying, the thickness of the kapok fiber web layer accounts for 0.45 of the total thickness of the nonwoven fabric, and the modal The thickness of the fiber web layer accounts for 0.55% of the total thickness of the nonwoven fabric; the double-layer fiber web layer is conveyed through the mesh curtain at a speed of 7m / min for mechanical reinforcement. The mechanical reinforcement method is acupuncture reinforcement, and the mechanical reinforcement direction is from the kapok fiber web layer to The modal fiber net layer is reinforced, and the first kapok fiber bundle in the kapok fiber net layer is embedded in the modal fiber net layer, and the length of the first kapok fiber bundle embedded section is 0.45 of the thickness of the modal fiber net layer; The fiber web is reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com