Fiber treating agent

A fiber treatment agent and general formula technology, applied in the field of fiber treatment agent, can solve the problems of decreased functionality and poor washing durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

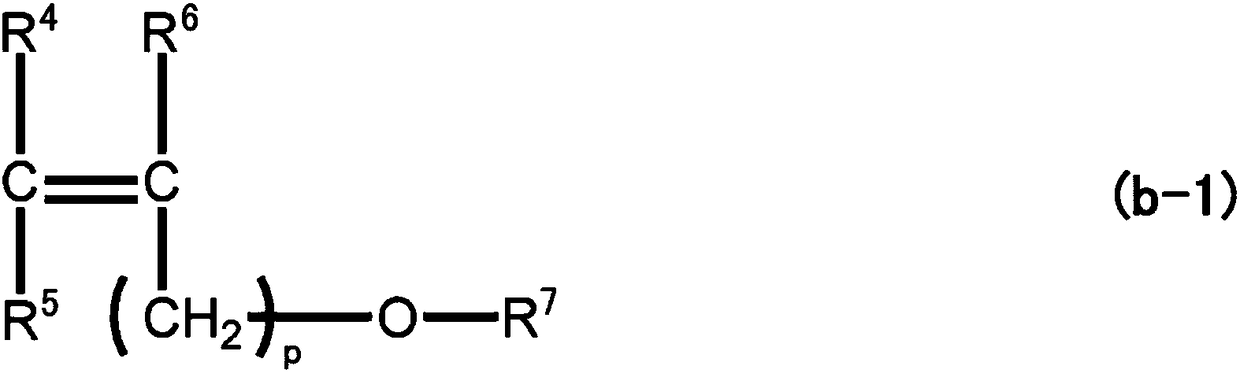

Method used

Image

Examples

Embodiment 1

[0177] 6024 g of 40% by mass 3-allyloxy-2-hydroxyl-1-propanesulfonate aqueous solution (hereinafter, abbreviated as 40% HAPS) was charged into a 25 L capacity SUS reaction vessel equipped with a reflux cooler and a stirrer , Warming up to the boiling point reflux state with stirring. Then, under stirring, 5670 g of 80 mass % acrylic acid aqueous solution (hereinafter referred to as 80 % AA), 6024 g of 40 % HAPS, and 2128 g of 15 mass % sodium persulfate aqueous solution were added dropwise to the polymerization reaction system in the boiling point reflux state. (hereinafter abbreviated as 15% NaPS) (corresponding to 3.8 g of monomers in 1 mol of monomer components). Based on the time point at which 80% AA was added (0 min), 80% AA was added dropwise between 0 min and 90 min, and 40% HAPS was added dropwise between 0 min and 60 min at a constant rate. 15% NaPS as an initiator was added dropwise at an addition rate of 9.7 g / min, and the addition rate was changed to triple 29.1 ...

Embodiment 2

[0182] Using the fiber treatment agent (1) obtained in Example 1, fiber treatment was performed on polyester fabrics, and evaluations of washing durability and hygroscopicity were performed.

[0183] The results are shown in Table 1.

Embodiment 3

[0185] 350.8 g of deionized water was put in a 2.5-L capacity SUS reaction vessel equipped with a reflux cooler and a stirrer, and the temperature was raised to a boiling point reflux state while stirring. Then, under stirring, to the polymerization reaction system in the boiling point reflux state, 630.0 g of 80% AA, 545.0 g of 40% HAPS, 260.0 g of 100% 2-hydroxyethyl methacrylate (hereinafter referred to as 100% HEMA), 267.0 g of 15% by mass sodium persulfate aqueous solution (hereinafter abbreviated as 15% NaPS) (corresponding to 4.0 g of monomers in 1 mole of monomer components), 133.3 g of 45% hypophosphorous acid Sodium monohydrate (hereinafter, abbreviated as 45% SHP). Based on the time point (0 minute) when the addition of 80% AA was started, 80% AA was added dropwise at a constant rate between 0 minute and 180 minutes. For 40% HAPS, it was added dropwise at an addition rate of 6.06 g / minute between 0 minutes and 30 minutes, and was added dropwise at an addition rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com