Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element using same

A liquid crystal aligning agent and liquid crystal technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of harsh characteristics of liquid crystal aligning films, etc., and achieve the effect of not being easy to flicker, promoting relaxation, and rapid accumulation of charge relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

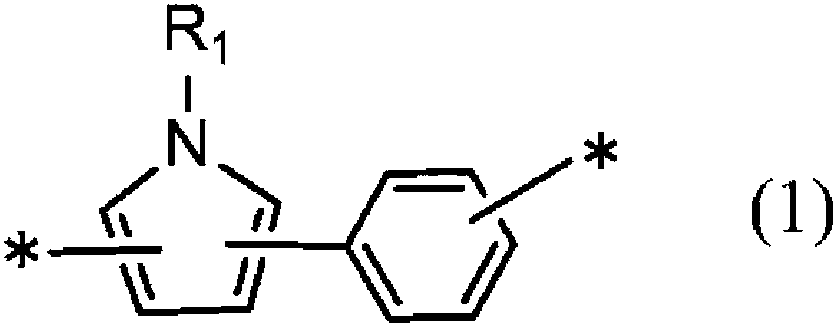

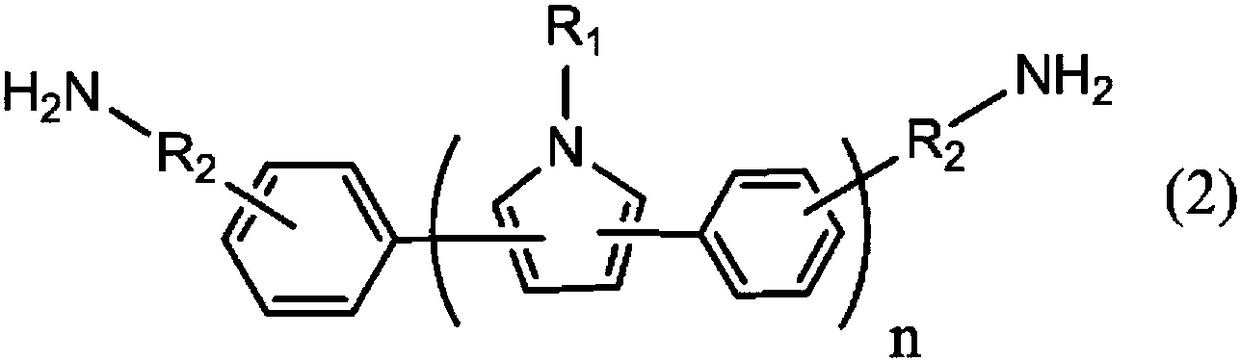

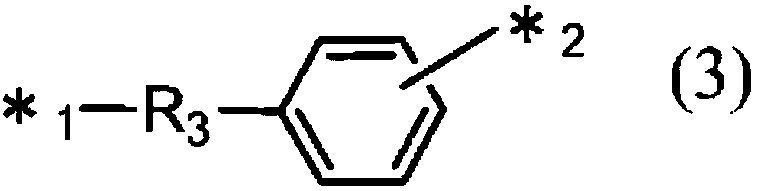

Image

Examples

Embodiment

[0141] Hereinafter, the present invention will be specifically described with examples and the like. In addition, this invention is not limited to these Examples. The abbreviations of the compounds used below and the method of characteristic evaluation are as follows.

[0142]

[0143]

[0144] In the above formula, Boc is a group represented by the following formula.

[0145]

[0146]

[0147] NMP: N-methyl-2-pyrrolidone, GBL: γ-butyrolactone,

[0148] BCS: Butyl Cellosolve

[0149]

[0150] LS-4668: 3-Glycidoxypropyltriethoxysilane

[0151]

[0152]

[0153] ( 1 H-NMR measurement)

[0154] Device: Varian NMR system 400NB (400MHz) (manufactured by Varian Corporation), and JMTC-500 / 54 / SS (500MHz) (manufactured by JEOL Corporation)

[0155] Determination solvent: CDCl 3 (deuterochloroform), DMSO-d 6 (Deuterated Dimethyl Sulfoxide)

[0156] Reference material: TMS (tetramethylsilane) (δ: 0.0ppm, 1 H) and CDCl 3 (δ: 77.0ppm, 13 c)

[0157]

[0158...

Synthetic example 1

[0176] After adding DA-1 (2.49 g, 10.0 mmol) to a 100 ml four-necked flask equipped with a stirring device and a nitrogen gas introduction tube, 29.0 g of NMP was added, and stirred while feeding nitrogen gas to dissolve it. After adding CA-2 (0.98 g, 5.0 mmol) and NMP 3.6 g (addition amount 1 in Table 1) while stirring this solution, it stirred at 25 degreeC for 1 hour. After that, CA-1 (0.87g, 4.0mmol) was added, NMP3.6g (addition amount 2 in Table 1) was added, and stirring was carried out at 50° C. for 12 hours to obtain a polymer having a resin solid content concentration of 12% by mass. Amic acid solution (PAA-A1). The viscosity of this polyamic acid solution was 300 mPa·s.

Synthetic example 2~16

[0178] Using the tetracarboxylic dianhydride component, the diamine component and the NMP amount shown in Table 1, respectively become the reaction temperature shown in Table 1, except that it was carried out in the same manner as Synthesis Example 1, thereby obtaining Polyamic acid solutions (PAA-A2)~(PAA-A9) and polyamic acid solutions (PAA-B1)~((PAA-B7) with solid content concentration and viscosity shown.

[0179] [Table 1]

[0180]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com