Method and process for treating salt-containing phenolic wastewater by virtue of silver phosphate compound photocatalyst

A composite light and catalyst technology, applied in chemical instruments and methods, water treatment of special compounds, light water/sewage treatment, etc., can solve problems such as wastewater treatment process limitations, achieve simple process and operation, and efficiently degrade mineralization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

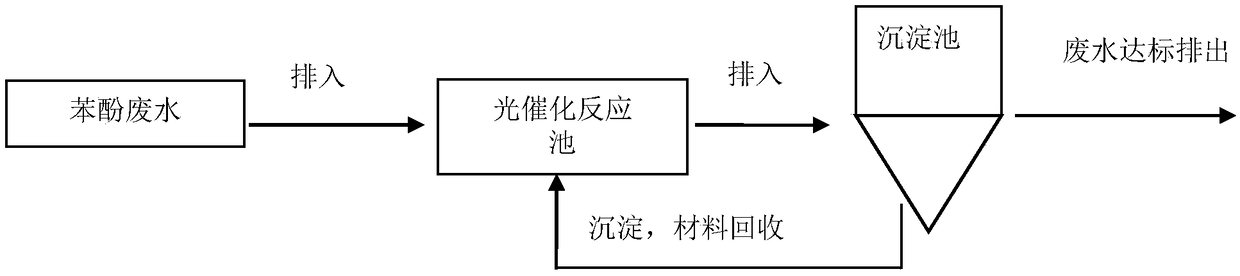

Method used

Image

Examples

Embodiment 1

[0031] Select phenol concentration as 25mg / L, Na 2 SO 4 Concentration 0.1mol / L, volume 10m 3 The phenol wastewater was used as the target pollutant, and 2kg of the prepared photocatalytic material was added, and the sunlight was used as the light source to degrade the pollutants. Specific steps are as follows:

[0032] (1) Weigh 2kg photocatalytic material in 10m 3 In the methylene blue wastewater, stir and mix.

[0033] (2) The waste water is introduced into the photocatalytic reaction pool under sunlight.

[0034] (3) Turn on the aeration device and start the reaction timing;

[0035] (4) Draw 3-4 mL of the reaction solution with a 5 mL syringe every 2 minutes, and pass the solution through a 0.22 μm water-based polyethersulfone filter head.

[0036] (5) The concentration of the solution obtained by filtration is measured by HPLC. At the same time, the reaction system without photocatalytic material was used as the blank control group, and the test results were as fol...

Embodiment 2

[0039] Select phenol concentration as 25mg / L, Na 2 SO 4 Concentration 0.1mol / L, volume 10m 3 The phenol wastewater was used as the target pollutant, and 2 kg of the prepared photocatalytic material was added, and the pollutant was degraded by using a xenon lamp as a light source. Specific steps are as follows:

[0040] (1) Weigh 2kg photocatalytic material in 10m 3 In the methylene blue wastewater, stir and mix.

[0041] (2) The wastewater is introduced into the photocatalytic reaction pool where the xenon lamp light source is turned on.

[0042] (3) Turn on the aeration device and start the reaction timing;

[0043] (4) Draw 3-4 mL of the reaction solution with a 5 mL syringe every 2 minutes, and pass the solution through a 0.22 μm water-based polyethersulfone filter head.

[0044] (5) The concentration of the solution obtained by filtration is measured by HPLC. At the same time, the reaction system without photocatalytic material was used as the blank control group, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com