Water-base environment-friendly crayon

An environmentally friendly and water-based technology, applied in pencil leads, household appliances, applications, etc., can solve the problems of difficult cleaning, easy slag removal, poor color rendering effect, etc., to achieve the effect of good hardness, environmental friendliness, and bright writing colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

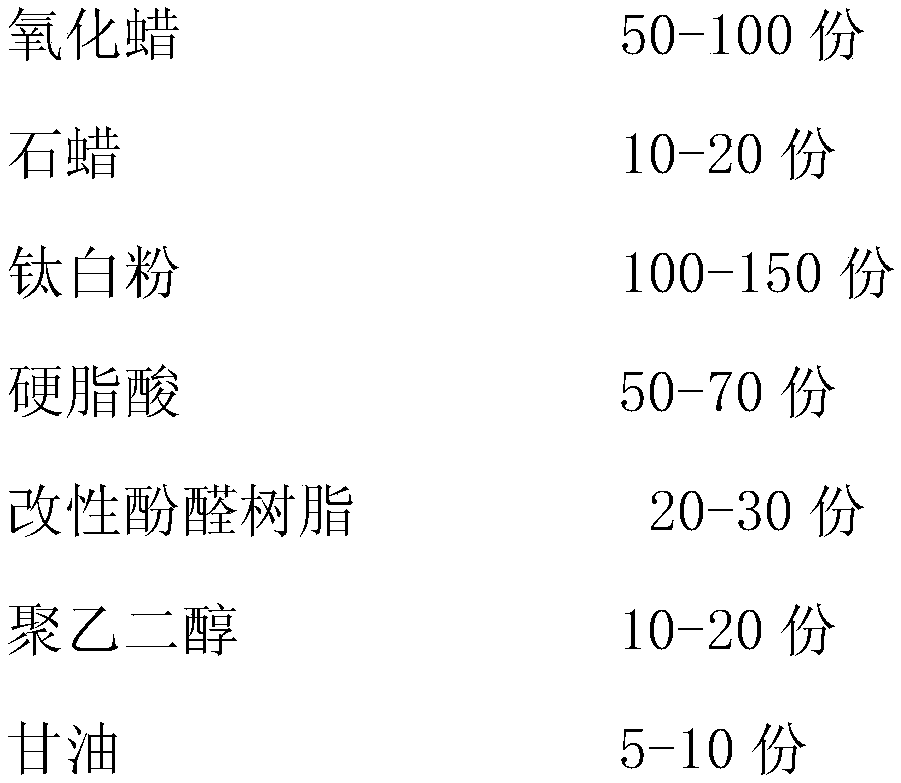

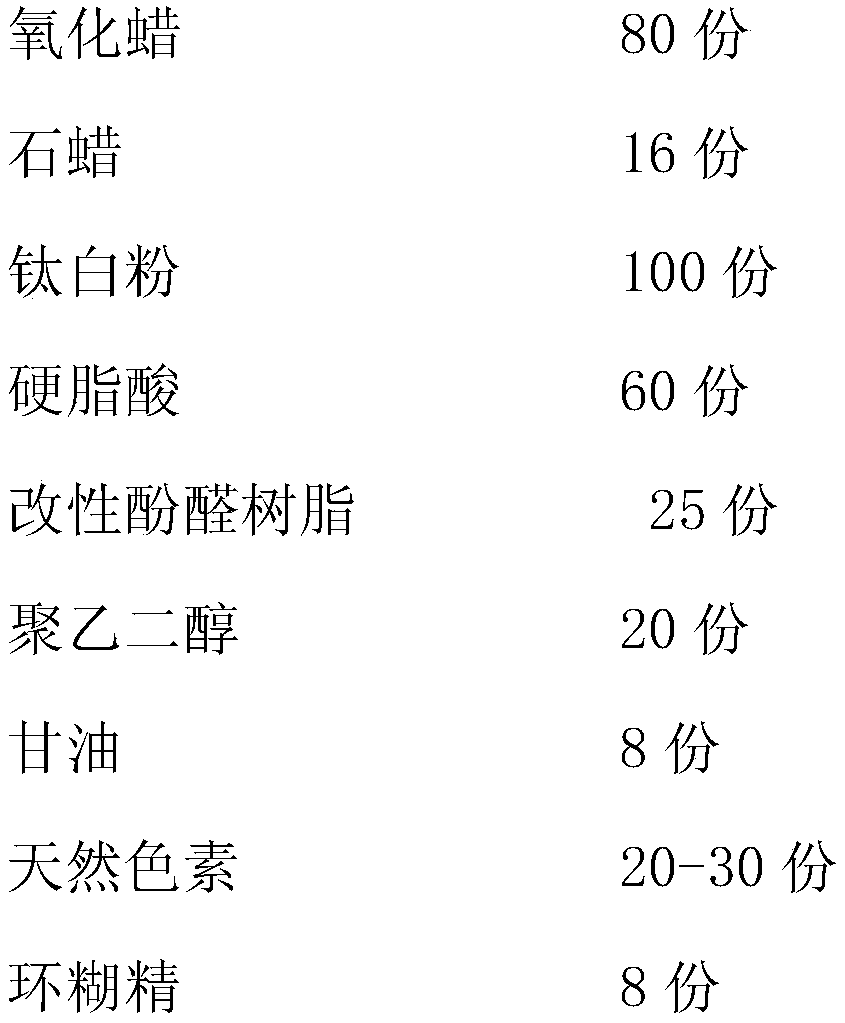

Method used

Image

Examples

Embodiment 1-9

[0026] Examples 1-9 provided by the present invention are produced according to the above-mentioned components through the following preparation method, which specifically includes the following steps:

[0027] S1. Add oxidized wax, paraffin wax, and titanium dioxide into the reaction kettle, heat and stir according to the ingredient formula, raise the temperature to 100-130°C, stir at a speed of 60-70 rpm, stir and mix for 1-1.5h, and cool down to 90°C;

[0028] S2. Add modified phenolic resin, polyethylene glycol, and glycerin into the reaction kettle according to the composition formula, heat and stir, keep the temperature at 90°C, stir at 60-70 rpm, and stir and mix for 0.5-1.0h;

[0029] S3. Add titanium dioxide, natural pigments, and cyclodextrin into the reaction kettle according to the ingredient formula, keep the temperature at 90°C, stir at a speed of 60-70 rpm, stir and mix for 0.5-1.0h, and cool;

[0030] S4. Bundle the mixed material in the reaction kettle twice o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap