A device and method suitable for preparing starch sugar by drying corn at high temperature

A technology of high-temperature drying and starch sugar, which is applied in the direction of sterilization methods, biochemical equipment and methods, methods of supporting/immobilizing microorganisms, etc., and can solve problems such as unrecyclable filter residue, poor liquefaction effect, and difficulty in saccharification and filtration , to achieve the effect of increasing the value of by-products, improving the liquefaction effect and saccharification effect, and reducing the content of modified starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

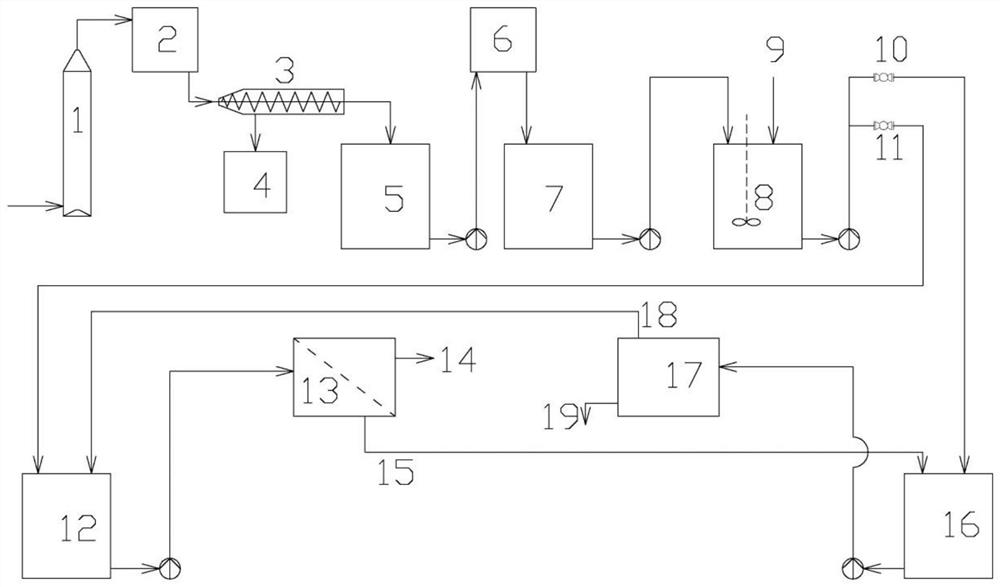

[0047]A device suitable for high-temperature drying corn to prepare starch sugar, including a starch milk separation unit disc separator for separating crude starch milk, a starch lotion unit, a solid-phase separation unit for separating liquefied liquid after starch lotion, and a saccharification flocculation unit for saccharification and protein flocculation.

[0048] The solid phase separation unit for separating liquefied liquid after starch lotion includes a primary cooling device, a horizontal screw centrifuge connected with the primary cooling device and a secondary cooling device connected with the liquid phase separation port of the horizontal screw centrifuge. After the primary cooling, the liquefied liquid is separated from the light phase and the heavy phase by the horizontal screw centrifuge, and the light phase enters the saccharification flocculation unit for saccharification after the secondary cooling. Protein drying device 4 connected to the solid phase separatio...

Embodiment 2

[0062] (1) The crude starch milk processed by high-temperature drying corn is separated by a disc separator to obtain gluten water and starch milk. The feed concentration of crude starch milk in the main separation disc separator is 10.0b é. After separation by the separator, the underflow concentration is 17.7b é and the top stream dry matter content is 2.5%;

[0063] (2) After liquefaction, the liquefied liquid with a temperature of 95 ℃ enters the plate heat exchanger for primary cooling, and the temperature of the liquefied liquid is reduced from 95 ℃ to 80 ℃ by adjusting the cooling water flow of the plate heat exchanger;

[0064] (3) The liquefied liquid after primary cooling enters the horizontal screw centrifuge for separation, and the feed flow is 13m 3 / h. The solid content in the feed is 1.2%, and the parameters of horizontal screw centrifuge are differential speed 10rpm and separation factor 3000. After separation by horizontal screw centrifuge, it is separated into so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com