Simply supported variable continuous bridge construction method with steel beam tensioning connector

A simple-support variable continuous bridge construction technology, which is applied in bridges, bridge materials, bridge construction, etc., can solve problems such as unreasonable structural forms and bridge quality problems, so as to improve connection reliability, shorten age differences, reduce The effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

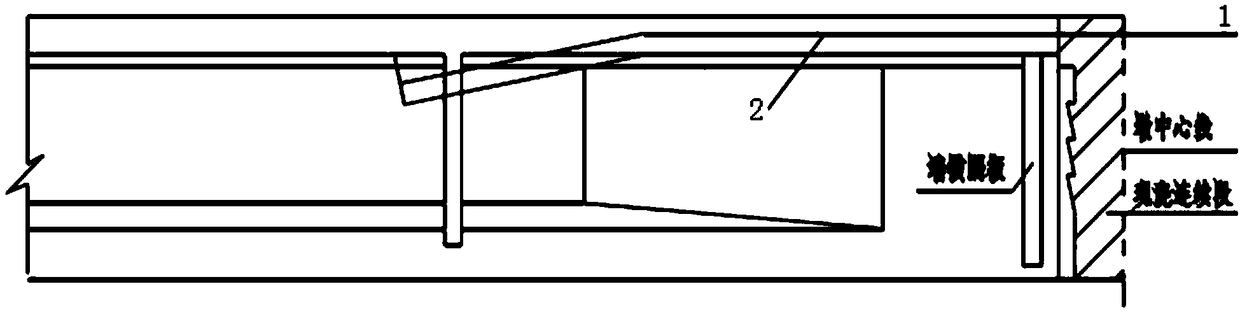

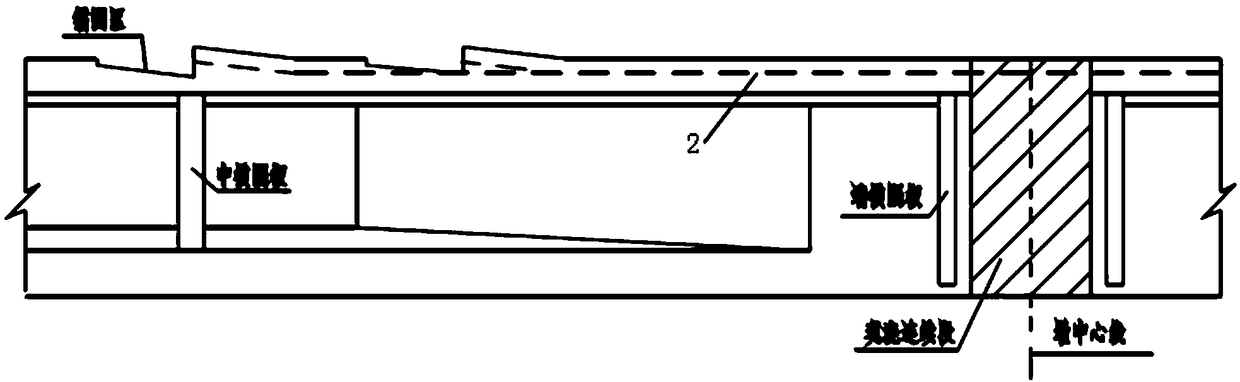

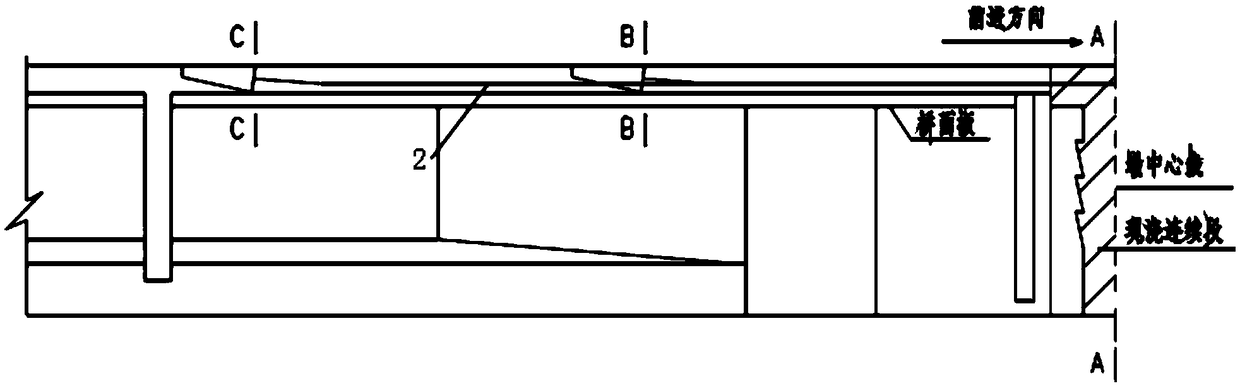

[0042] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0043]The steel beam tension connector set in the bridge includes a bellows 1 and a steel beam 2 inserted in the bellows 1. An anchoring device 3 is provided at one end of the steel beam 2, and a connection with the other end of the steel beam 2 is also included. The tightening mechanism 4 ; the connection tightening mechanism 4 is mainly composed of a steel beam anchor 41 and a connection tightener 42 , the connection tightener 42 is set outside the steel beam anchor 41 and cooperates with the outer peripheral thread of the steel beam anchor 41 . The anchoring device 3 is composed of a conventional structure, including an anchoring block 31 clamped at the end of the steel beam 2 and an anchoring steel plate 32 matched with the anchoring block 31 , and also includes a helix that is sleeved outside the bellows 1 and located inside the anchori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com