Heat pump drying system

A heat pump drying and heat pump system technology, applied in drying, dryer, fluid heater and other directions, can solve the problems of air pollution, heat waste, unfavorable sustainable development of the national economy, etc., and achieve recycling and enhancement effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

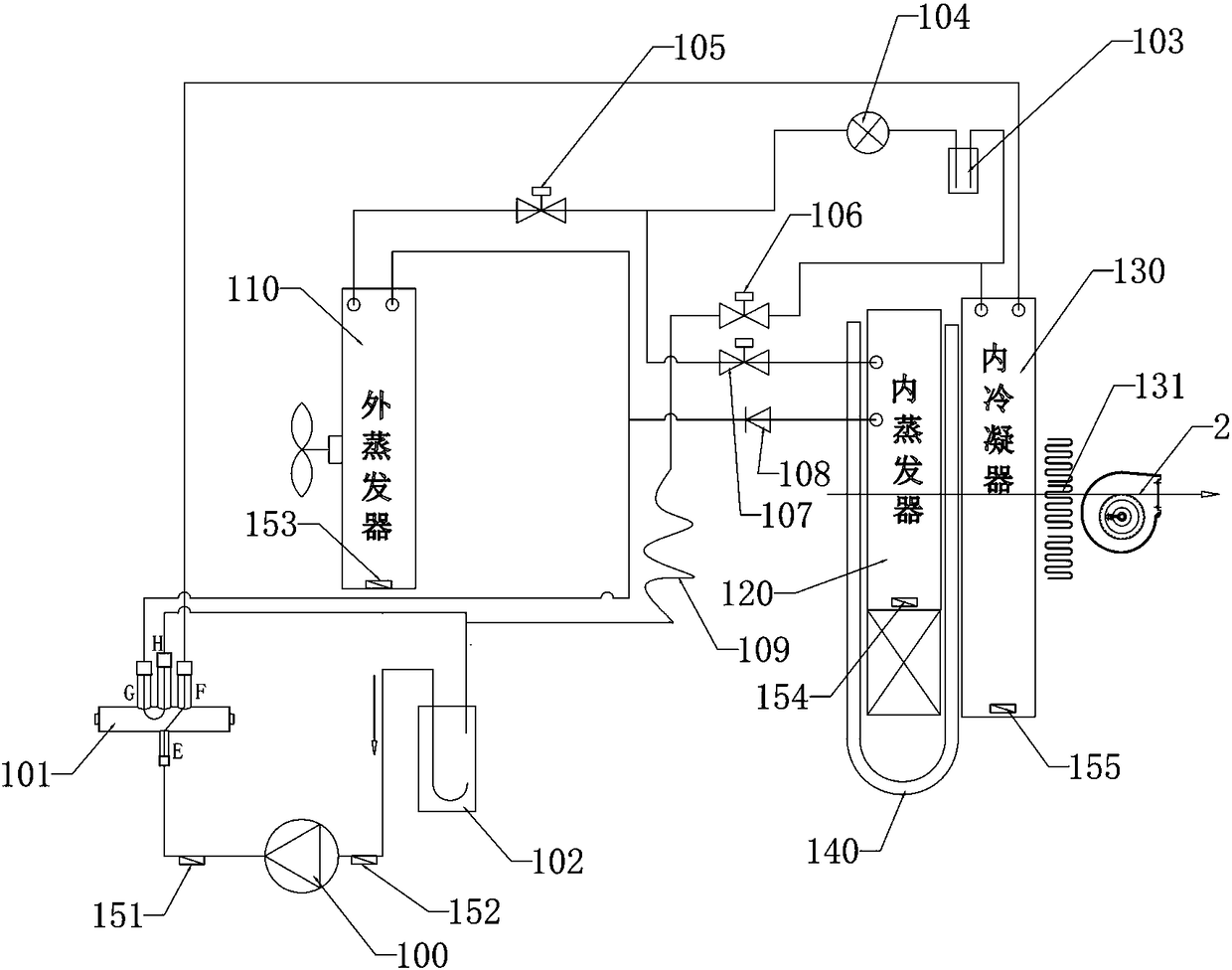

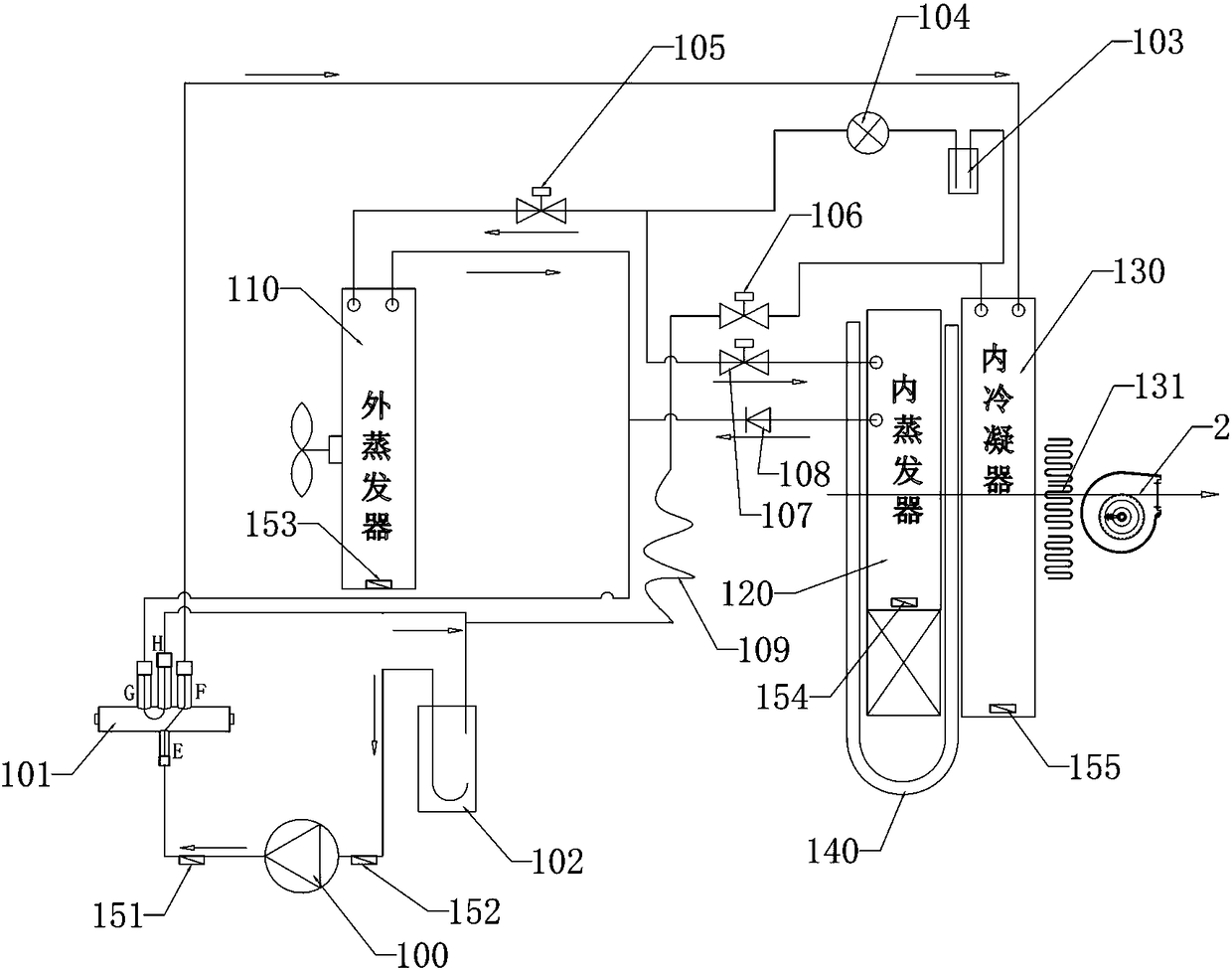

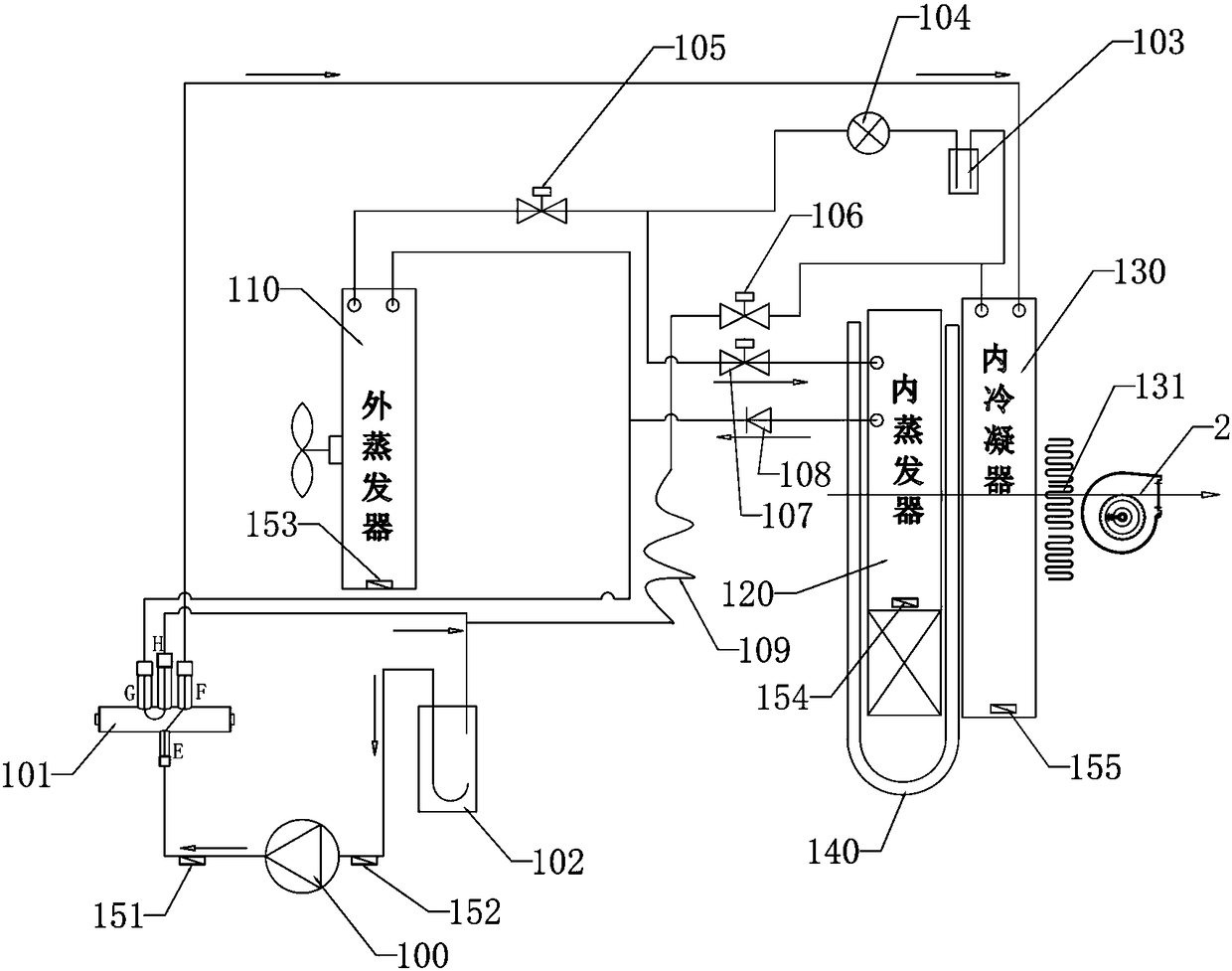

[0018] See attached figure 1 to attach Figure 4 As shown, in this embodiment, a heat pump drying system includes a heat pump system, a heat pipe 140 unit and an auxiliary heating unit 131, wherein the heat pump system includes a compressor 100, a four-way valve 101, and an outdoor heat exchanger 110 , internal evaporator 120, internal condenser 130, vapor-liquid separator 102, liquid reservoir 103, liquid injection solenoid valve 106, throttling unit 109, expansion valve 104, first solenoid valve 105, second solenoid valve 107, the first Three solenoid valves and the first one-way valve 108; the four-way valve 101 includes E, F, G and H ports, wherein, the ports E and F of the four-way valve 101 communicate in the four-way valve 101 and the ports G and The interface H communicates in the four-way valve 101; the output port of the compressor 100 communicates with the interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com