Non-ideal explosive detonation power capability and power measuring device

A power measurement, non-ideal technology, applied in the direction of ammunition, ammunition testing, weapon accessories, etc., can solve the problems of inability to guide formulation kinetic design, unable to characterize the energy output structure of explosives through functional evaluation, and overcome the shortcomings of pressure relief. 、Accurately do functional force measurement to ensure continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

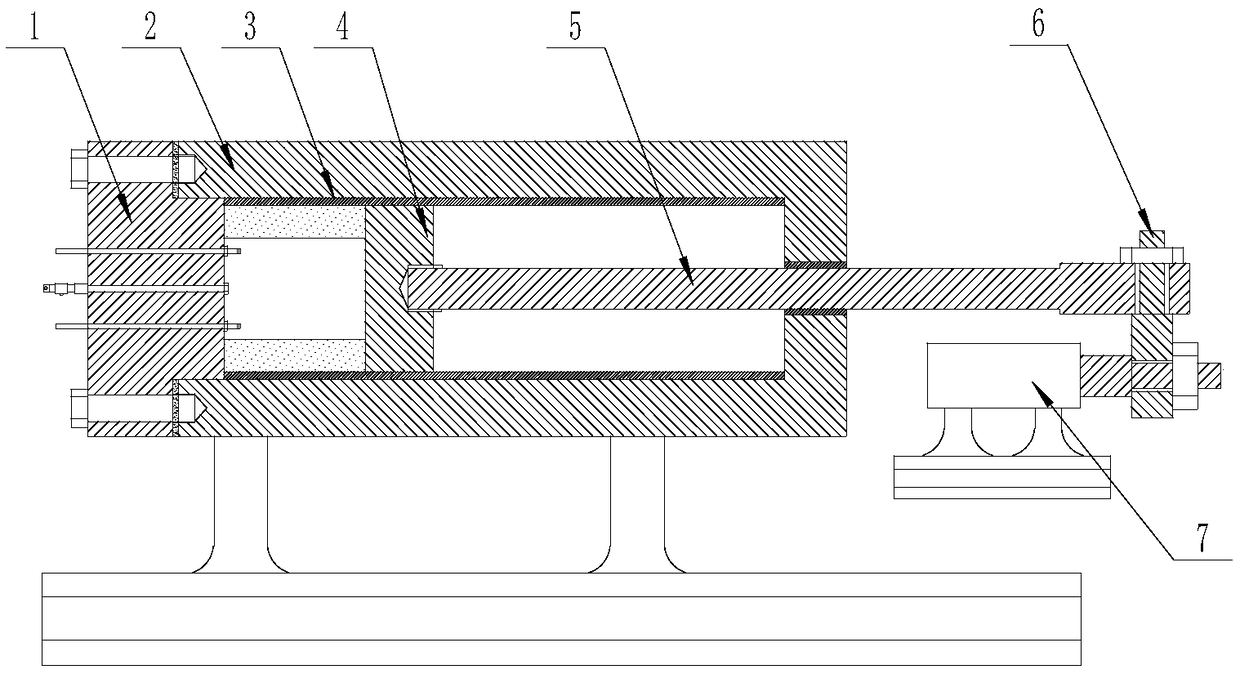

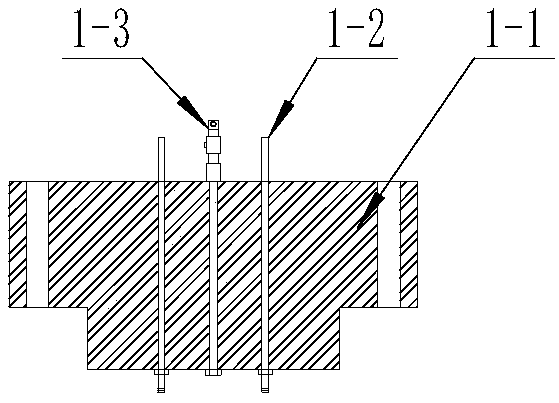

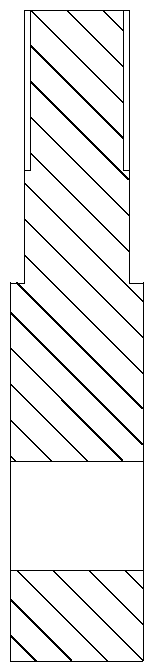

[0020] refer to Figure 1 to Figure 3 , the present embodiment provides a specific structure and manufacturing and assembly examples of a non-ideal explosive detonation work ability and power measuring device. The non-ideal explosive explosion work ability and power measuring device at least includes an explosion chamber end cover 1, an explosion chamber body 2, a nylon sleeve 3, an impact end cover 4, a piston rod 5, a connecting rod 6, a hydraulic damper 7, and a base 8 , Ceramic shell 9.

[0021] refer to figure 1 , the explosion chamber 2 is a horizontal cylinder, integrally cast from stainless steel, with an outer diameter of 310mm to 360mm, an overall length of 500mm to 600mm, a thickness of 30mm to 40mm on the right side, and an opening at the left end with a depth of 60mm to 80mm. Internally threaded, with a circular through hole in the center at the right end. Nylon sleeve 3 is made of round tubular nylon, 440mm-520mm in length, 220mm-260mm in outer diameter and th...

Embodiment 2

[0026] This embodiment provides an example of measuring the explosive performance of a certain aluminum-containing non-ideal explosive by using a device for measuring the explosive performance and power of a non-ideal explosive manufactured in Example 1.

[0027] The formula of the non-ideal explosive used in this example is 65RDX / 30Al / 5 viscosity, and a compression molding process is adopted to prepare a cylindrical explosive column with a diameter of 40 mm and a mass of 50 g. The assembly process adopts the method used in Example 1, and the test result is that the work is 127.5kJ, the work force is 2.55MJ / kg, and the peak work power is 3.35MW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com