Sensing method of fiber grating earth sound sensing system

A sensing system and sensing method technology, applied in the sensing field of fiber grating geoacoustic sensing system, can solve the problems of limited sensitivity improvement, complex preparation process, complex system, etc., and achieve easy industrial production, simple physical structure, The effect of strong system adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are described in further detail below in conjunction with accompanying drawings:

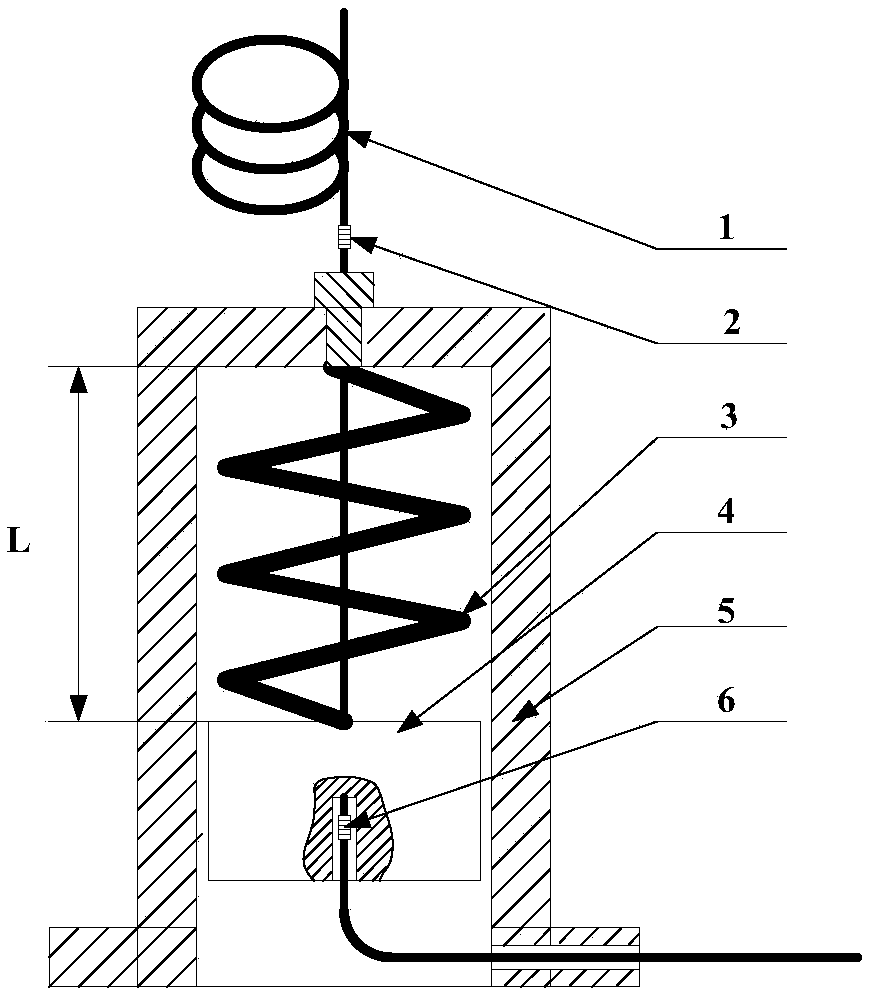

[0028] The structure of the fiber grating geoacoustic sensing probe of the present invention is as follows: figure 1 As shown, it includes an optical fiber 1 , a first chirped grating 2 , a spring 3 , a proof mass 4 , a second chirped grating 6 , and a barrel 5 . The mass block 4 is suspended on the inner wall of the cylinder, and the center top of the cylinder body 5 is provided with an introduction hole. The optical fiber 1 is introduced through the introduction hole of the cylinder body 5, and after passing through the mass block 4, the other end is drawn out from the export hole opened on the support of the cylinder body 5 . One end of the spring 3 is connected to the mass block 4 , and the other end of the spring 3 is connected to the cylinder body 5 ; one end of the optical fiber 1 is cemented to the mass block 4 , and the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com