Online detection system and method for ammonia gas concentration plane distribution at outlet of SCR

A technology of plane distribution and detection system, applied in the measurement of color/spectral characteristics, etc., can solve the problems of large maintenance, unrepresentative single-point measurement results, low measurement efficiency, etc., to reduce equipment costs and maintenance costs, shorten the network. The effect of the format detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing and example, but the implementation and protection of the present invention are not limited to this, it should be pointed out that if there are no special details below, those skilled in the art can refer to existing technically understood or realized.

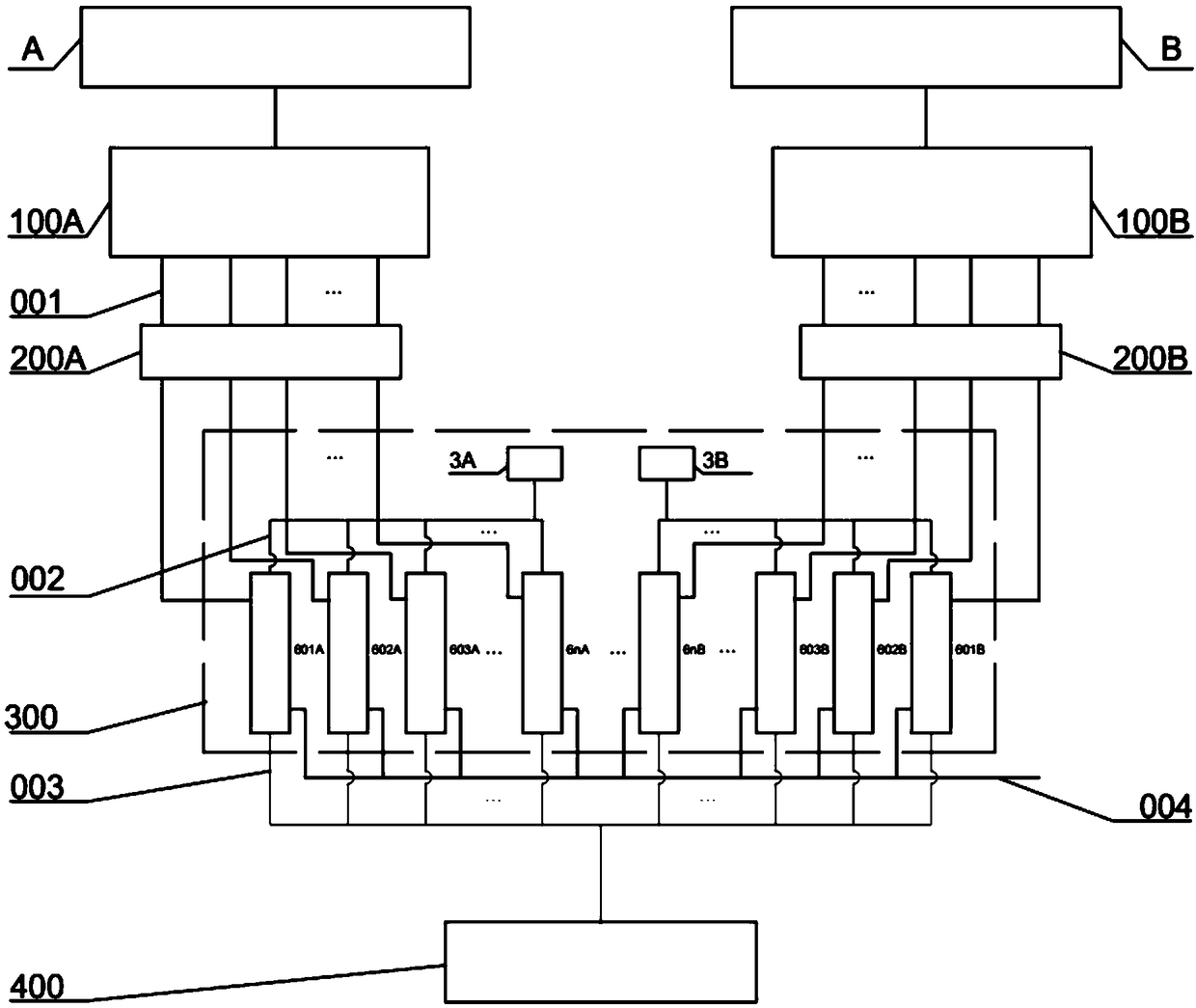

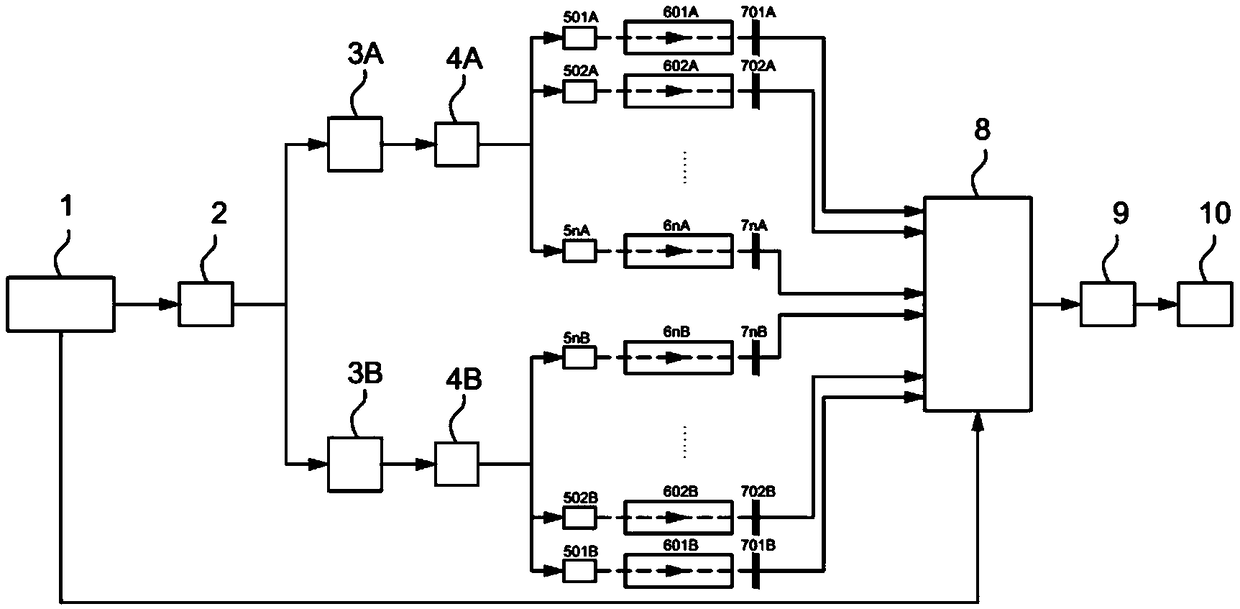

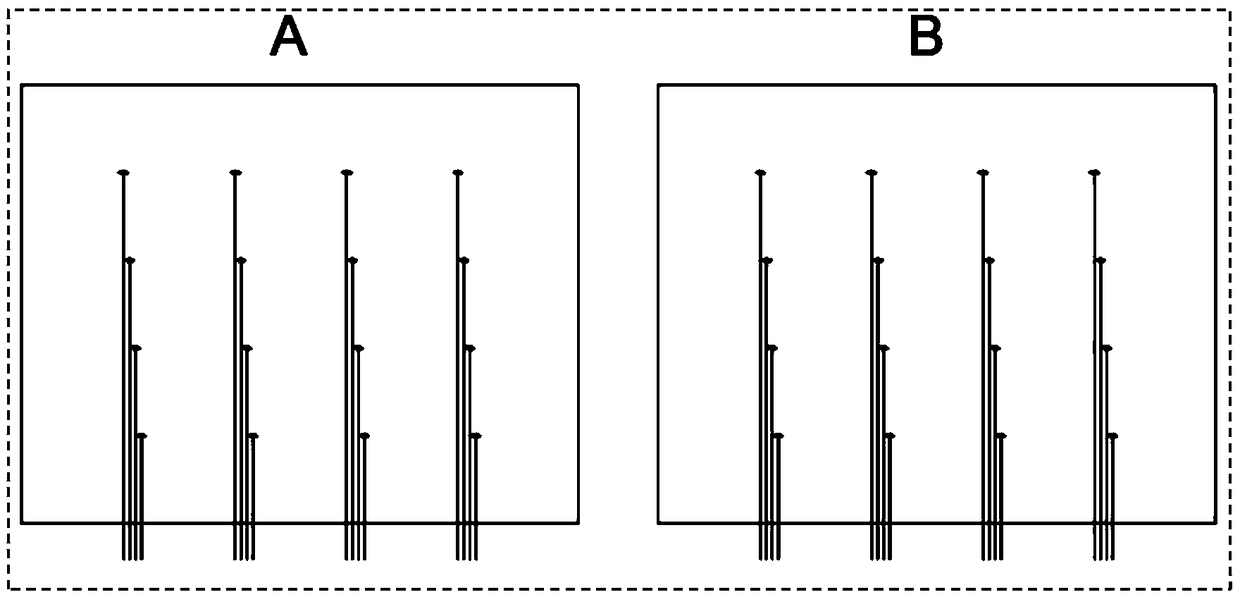

[0024] A kind of SCR outlet ammonia concentration plane distribution online detection system of this example, such as figure 1As shown, it includes flue (A, B), two sampling modules (100A, 100B), two flue gas pretreatment modules (200A, 200B), laser detection module 300, data processing and display module 400, electric heating pipe 001, signal line 002, optical fiber 003, exhaust pipe 004, two lasers (3A, 3B), gas absorption cell (601A / 602A / 603A… / 6nA / 601B / 602B / 603B… / 6nB).

[0025] In this example, the first sampling module 100A and the first flue gas pretreatment module 200A are arranged corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com