Multi-degree-of-freedom micro-vibration diagnosis method and sensing terminal

A diagnostic method and micro-vibration technology, applied in earth-moving drilling, instrumentation, design optimization/simulation, etc., can solve the problems of asynchronous data being unable to be truly synchronized, limited sensing range, single function, etc., to achieve large-scale mass production and low-cost Cost-mass deployment capability, ensuring high-precision synchronization, and the effects of strong data correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

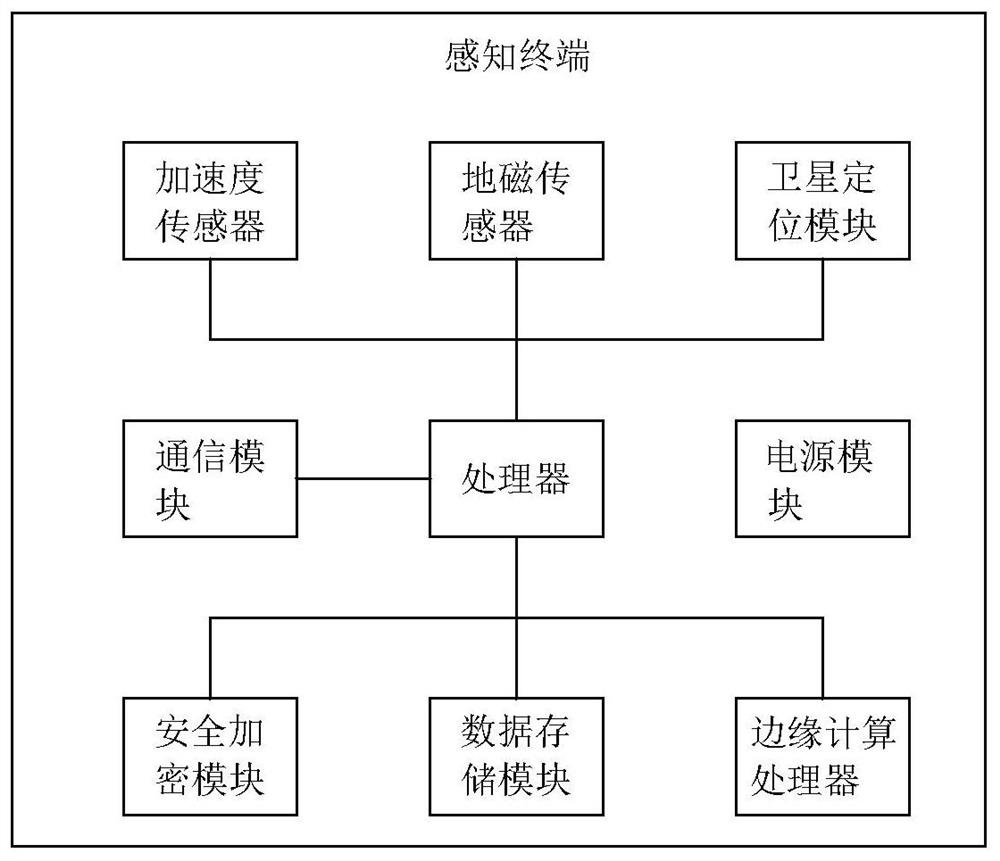

[0034] The invention provides a multi-degree-of-freedom micro-vibration diagnosis method and a sensing terminal, which solves the problems of low data reliability, installation of multiple single-function sensors, complex installation, high construction cost, inconvenient data communication, and data synchronization in the prior art. Low performance, poor timeliness, unable to give dynamic simulation on the software platform, and give a preliminary diagnosis and other deficiencies.

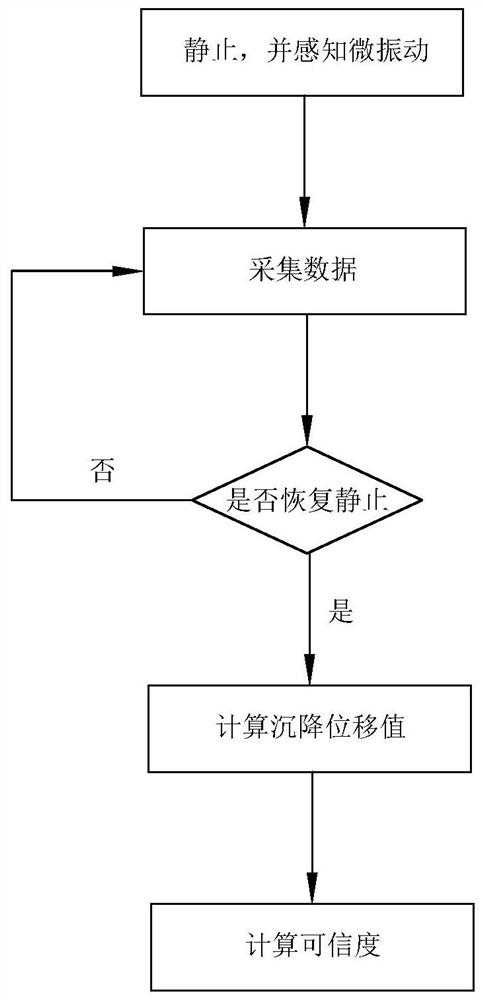

[0035] The multi-degree-of-freedom micro-vibration diagnosis method of the present invention, such as figure 1 As shown, the steps are as follows:

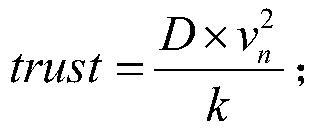

[0036] Step 1), the acceleration sensor is used to determine whether there is vibration or disturbance (usually micro-vibration) at the observation point, and if so, the acceleration sensor performs data collection u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com